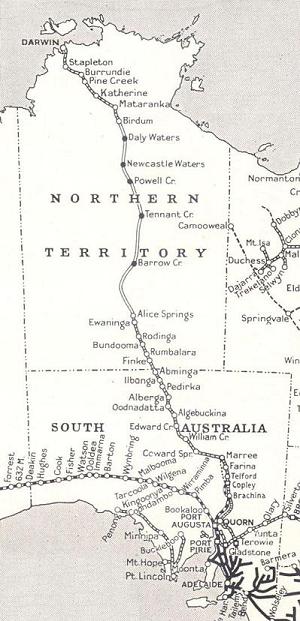

A line drawn between Darwin and Port Augusta roughly approximates the route of an incomplete narrow gauge Australian north-south transcontinental route. Work commenced on the southern section of the route in 1879 with the last additions completed in 1929 when Alice Springs was reached. The northern section saw construction commence from Palmerston (later Darwin) in 1883, with Birdum reached in 1929, although the effective terminal was at Larrimah. During the operation of the NSU Class locomotives the substantial gap between Alice Springs and Birdum would remain. (This lengthy gap would not be closed until a new standard gauge railway of 1,420km was completed between Darwin & Alice Springs, with freight and passenger services operating by February 2004). Operation of the southern route had been under the control of the Commonwealth Railways since 1911, the northern section not coming under their control until 1918. During the early 1950's the prospect of dieselisation beckoned, the advantages of which would not only bring cost savings but an improvement in dealing with the onerous conditions in this hot desert region. This included a scarcity of water, all of which required treatment, though in many cases the quantity of water made it uneconomic and some of the water even after treatment was harmful to the steam locomotive boilers.

Like many other railways throughout the world the Commonwealth Railways had seen its physical assets suffer from increased use during World War II with minimal maintenance taking place during this period, which was not helped by the harsh conditions encountered over this route. With the war over and the economic situation easing, funds became available to invite tenders for new diesels to replace the aging steam locomotives currently working the route. The tenders required the applicants to fulfill some important needs:

Axle loading of no more than 10.5 tonnes (in order to operate over lightly laid rail of 41lb, 50lb & 60lb per yard).

Electric transmission

Three axle bogies

Tractive effort of at least 21,000lbs

Ability to operate in extreme conditions, with temperatures in excess of 45C, poor quality water and dry & dusty air, heavily laden with sand. The greatest altitude was only 190 feet, temperatures and humidity varied but the Central section (Port Augusta - Alice Springs, 771 miles) endures long periods of 100F+ temperatures, with highs to 120F.

Capacity to haul 202 tons up a 1 in 60 uncompensated grade with main line curves of 7 chains radius and sidings with 4 chains radius.

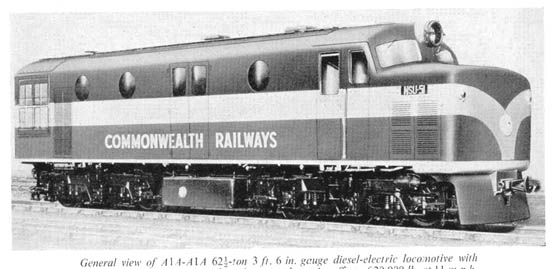

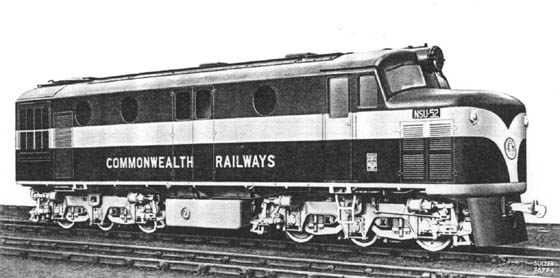

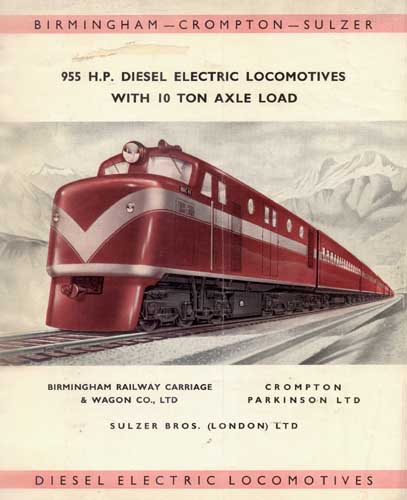

Over thirty designs were submitted with most failing to comply with the conditions stated. Many were rejected because of the Commonwealth Railways preference for a slow speed engine coupled to an electric transmission. In 1951 the contract was awarded to BRCW but with Sulzer, because of its long experience in the industry being responsible for all matters related to the new locomotives. BRCW did have a long history of building rail vehicles but this order was its first involving the construction of locomotives.

Because of the presence of standard gauge track in the Port Augusta area the order for the new diesels therefore included four standard gauge bogies to permit two locomotives to operate over these lines, this however seems not to have been a frequent occurrence.

The ruling grade was 1 in 60 with 460 feet uncompensated curves. Specified trailing loads were:

Port Augusta - Quorn: 25 miles: passenger 162 tons, freight 202 tons

Quorn - Copley: 139 miles: passenger 264 tons, freight 330 tons

Copley - Marree - Oodnadatta - Alice Springs: 607 miles: passenger 344 tons, freight 430 tons.

At the time of the placing of the order for the BRCW diesels the services on both lines was limited. A mixed train ran weekly over the entire length of the Central route, a bi-weekly service ran as far as Marree. Freight trains were more frequent on the southern half of the route, particularly coal from the Leigh Creek area. Passenger journeys on the Northern section were about one tenth of the Central line, freight tonnage was about 10,000 tons per annum.

Maximum speed was 50mph on the most favourable sections, an over-speed relay activated at 53mph, which reduced power and applied the brakes, normal control then became available at 45mph. Air brakes were standard on Central region trains, the Northern train relied on automatic vacuum.

The freight timetable for steam service between Port Augusta & Alice Springs allowed six hours 'standing time' en-route, which included three mechanical examinations at Marree, Oodnadatta & Abminga in addition to coaling & watering. This time would be almost completely eliminated with the arrival of the new diesels.

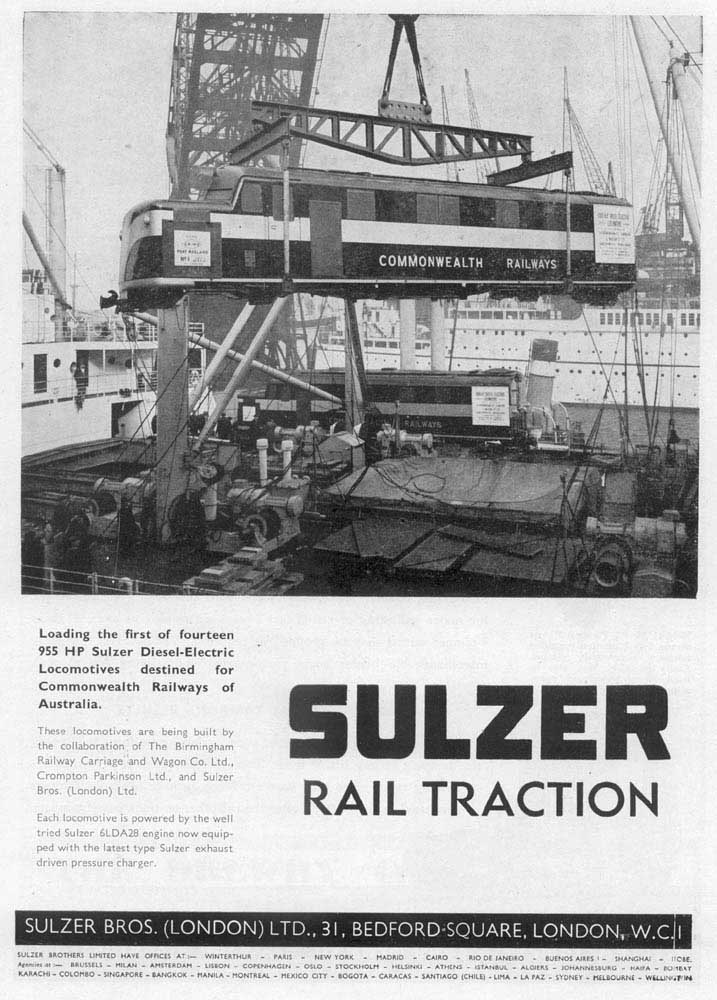

An order for fourteen locomotives was placed with the Birmingham Railway Carriage & Wagon Co Ltd as main contractor, with the engine and auxiliary equipment supplied by Sulzer Brothers (London), electric transmission and control equipment was provided by Crompton Parkinson Ltd. Because of the long history of Sulzer in this field they were asked to assume full technical responsibility for the entire design.

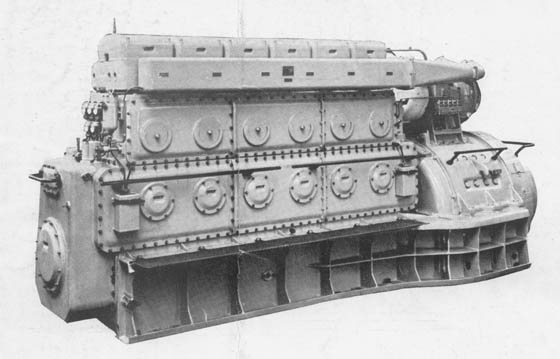

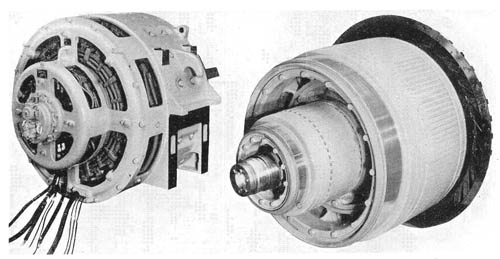

The power unit was a Sulzer 6LDA28 pressure-charged vertical four stroke with six 280mm by 360mm (11in by 14.2 in) cylinders. For the local Australian conditions the one hour rating was set at 955hp at 750rpm, continuous output was 850hp at 700rpm. Dry weight including mounted accessories was 20,000lb. The engine followed the normal Sulzer practices of a welded mild steel crankcase with cast steel tranversals welded in, crankcase & engine-generator underbed as an integral structure; welded steel cylinder block bolted to the crankcase with cast iron wet cylinder liners inserted; U-shaped main bearing saddles with top caps let into the crankcase structure - to increase the lateral strength of the frame and having no bearing studs in shear; a toothed wedge locking & adjusting device allowed bearing adjustments as fine as 0.1mm.

One inlet and one exhaust valve were housed in each cylinder head. The forged aluminium alloy pistons carried five pressure and two scraper rings and drove fully machined and polished I-section chrome nickel steel rods with white metalled bearings on the crankpin and four-bolt big ends provided with special toothed locking of the nuts. The crankshaft steel was fully annealed, large white-metalled bearings allowed soft steel to be used for the shaft. At the forward end of the shaft a Sarazin vibration damper allowed safe operation at any rpm. Individual Sulzer fuel injection pumps with double helix plungers were fitted, they and the engine inlet and exhaust valves were actuated from a gear driven camshaft.

The Sulzer exhaust gas pressure charger was carried on the main generator frame, it was a plain-bearing machine with a high-efficiency impeller of special aluminium alloy, the turbine rotors were made up of milled steel blades. A Sulzer centrifugal air cleaner was fitted at the pressure charger inlet.

The main generator was a ten pole machine with continuous ratings of 535kW at 700rpm 535 volts 1,000 amp and 520kW at 700rpm 800 volts 650 amp, maximum voltage is 900 and maximum current 1,540 amp. The magnet frame was of cast steel, armatures were combined on a common rotor which is of cast steel bottle form. Tandem brushes were used, the brush holders were carried on a revolving rocker with a rack & pinion arrangement allowing rotation for access to the brush holders. Rating of the eight-pole auxiliary generator was 63kW continuous at 500 to 750rpm 110 volts 575 amp. The auxiliary generator was recessed into the main machine.

The four traction motors were rated at 197hp 300 amp 550 volts one hour and 165hp 250 amp 550 volts continuous. Ratio of the single-reduction non-resilient gears was 14:65. The four traction motors were in permanent parallel with field weakening introduced automatically at three stages by electromagnetic contactors operated automatically when the generator excitation reached its maximum.

The control gear was designed & constructed by Allen West & Co Ltd to specifications provided by Crompton Parkinson Ltd. Two cubicles housed this equipment, the main one situated near the generator, the cubicle containing the auxiliary gear was at the other end of the engine room. The main motor contactor group and the reverser were electro-pneumatically operated; the weak field contactors and all the auxiliary contactors were of the electromagnetic type.

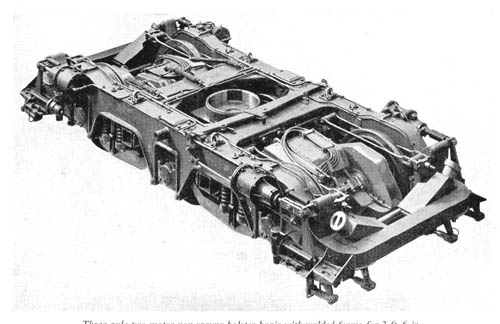

A completely welded superstructure of steel plate and pressed sections was riveted to a completely welded underframe. The main longitudinals were of box section and were used as ducts to distribute air to the traction motors. End buffing loads and equipment weight was carried entirely by the underframe. The main transoms were specially designed to accommodate the low position of the centre pivots. From the cab bulkhead forward the flooring was of steel plate, forming part of the strengthened nose area. Removeable roof panels allowed for the complete removal of the engine/generator set, or of the smaller components. Because of the extemely sandy conditions encountered, the engine room was pressurised through the installation of two Keith Blackman electrically driven fans at diagonally opposite corners of the engine room. Forced upwards, then downwards this deposited the larger particles at floor level, the finer material was captured by oil wetted Visco air filters prior to the air entering the engine room. Pressure release was through three air outlet traps, two in the engine room roof and one in the cab.

The cab nose housed the Crompton Parkinson 48-cell lead acid battery of 243 amp/hr capacity, at the five hour rate of discharge. Also housed in the nose were the air reservoirs and lockers for the crew's belongings.

Bogie frames were single welded steel structures, as was the bolster, both these assemblies being stress relieved. Main members were of box form though the side members were of open box shape to accomodate the equalisers. The bogie was of the swing bolster type though the bolster was not itself sprung. Nests of helical springs between the side equalisers and the frame formed the primary suspension. The springing was soft to provide easy riding over the light tracks, assisted by twin Newton Bennett shock absorbers to minimise the bounce. The swing links were on knife edges, the side swing stabilised against horizontal pre-loaded rubber springs. Side motion was finally limited by rubber stops.

Timken roller bearing axleboxes had thrust faces and liners of manganese steel, which was also used for the thrust faces on the bolster & bogie transoms. To prevent the bogie slewing round in the event of a derailment bogie-underframe interlocks were fitted, this would also stop the body from lifting off the bogie.

The brake system was the Australian Westinghouse A7-EL standard, interchangeability being achieved through the manufacture of certain components in Australia. Each bogie carried four horizontal brake cylinders and standard pattern of slack adjusters. Air was provided by a Westinghouse 2C.100 two cylinder reciprocating compressor. On the two machines destined for the Darwin - Birdum route one cylinder acted as an exhauster. Air was also used to operate the sanding gear and the electro-pneumatic control gear. Fuel was carried in a 700 gallon tank slung under the frame between the bogies, additionally a fifty gallon service tank was situated in the engine room roof space.

Two Serck radiators provided the means for cooling the water and lubricating oil. Electrically driven fans pulled air up through the side mounted radiators. The speed of the motor was connected electrically to the traction motor blower group, running at reduced speed until the controller was opened above notch 5 - there were 18 positions available.

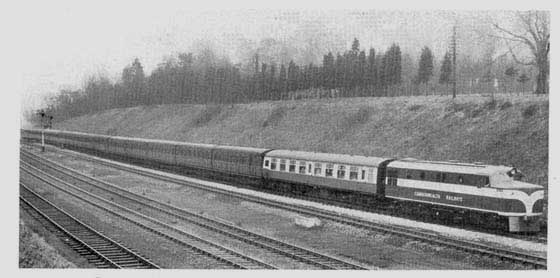

Prior to shipping the first locomotive made several test runs on British Railways between Smethwick, Birmingham & Banbury, using two of the four standard gauge bogies. The first locomotive was destined for the Central section & was therefore air brake equipped, this required the use of an ex-LNER quintuple articulated suburban set, a specially piped new BR saloon was provided for guests and observers. Maximum load was 360 tons trailing. The test run from Banbury to Birmingham Snow Hill on February 25th 1954 ran with a load of 250 tons trailing. The 45.75 miles was covered in 80 minutes, maximum speed was 50mph, with half a dozen 20mph restrictions through certain stations due to restricted clearances.

Another view of the test train, the locomotive features a decal on the nose, which appears to have been removed prior to shipment of the locomotives.

Photographs courtesy Donald Luscombe / collection of webmaster.

The locomotives were shipped through Liverpool to Port Augusta.

![]()

| Locomotive | Builders Number | Delivered | Withdrawn |

| NSU51 | DEL 1 | June 3rd 1954 | ?? - to Pichi Richi Rly 1980 - spares for NSU 52 | NSU52 | DEL 2 | May 26th 1954 | ?? - to Pichi Richi Rly April 1982 | NSU53 | DEL 3 | July 27th 1954 | 9/82 - Ghan Preservation Soc; Alice Springs | NSU54 | DEL 4 | December 15th 1954 | ?? - to Pichi Richi Rly 1983 - spares for NSU 52 | NSU55 | DEL 5 | December 24th 1954 | ?? - to Steamtown, Peterborough 1994 | NSU56 | DEL 6 | December 31st 1954 | ?? - abandoned at Marree | NSU57 | DEL 7 | February 2nd 1955 | 1980 - abandoned at Marree | NSU58 | DEL 8 | January 14th 1955 | ?? - Ghan Preservation Soc; Alice Springs July 1988 | NSU59 | DEL 9 | March 8th 1955 | ?? - Ghan Preservation Soc; Alice Springs | NSU60 | DEL 10 | February 18th 1955 | 1980 - abandoned at Marree | NSU61 | DEL 11 | March 20th 1955 | 1980 - Port Dock Station Rly Museum 1988 | NSU62 | DEL 12 | May 25th 1955 | 1980 - to Steamtown Peterborough 1994 | NSU63 | DEL 13 | July 9th 1955 | 1982 - on display Adelaide River NT (south of Darwin) | NSU64 | DEL 14 | October 12th 1955 | 1982 - to Ghan Preservation Society; Alice Springs |

NSU 51 & NSU 54 are held by the Pichi Richi Railway Preservation Society to provide a source of spares for NSU 52, which with NT 76 are used on a regular basis for tourist trains through the Pichi Richi Pass during the fire ban season when steam locomotives are not permitted. They are also used as general shunting locomotives around Port Augusta & Quorn including track work and ballast trains.

Miscellaneous Notes

This page was not meant to be a detailed historical document on the individual locomotives, however a number of contributors have supplied information which may be of definate interest:

May 20th 1954

NSU 51 & 52 and two sets of standard gauge bogies were offloaded from the 'Empire Star' on May 20th 1954 by an SA Harbors Board 60 ton floating crane to No.20 Berth, Port Adelaide. The locomotives was lowered on to SAR 5ft 3in gauge bogies for movement to Port Pirie Junction and on to Port Augusta.

The first two BRCW diesels were placed into service during June 1954, the third went into service during July 1954 after which there was a six month break before delivery restarted. The locomotives had a fuel range of about 700 miles with a trailing load of 330 tons at a maximum speed of 50mph. This fuel capacity will allow those on the northern section of the line to make a Darwin - Birdum round trip without refuelling. When all twelve diesels hade been delivered, along with four Gloucester Railway Carriage & Wagon Co Ltd diesel hydraulic railcars, they would replace twenty two steam locomotives over the narrow gauge route. The diesels were expected to cut at least five hours from the steam schedule between Marree and Alice Springs and with the completion of the standard gauge line to Marree in 1957, a total of twelve hours would be cut from the steam powered Adelaide - Alice Springs service.

June 12th 1954

The fast diesel electric locomotive service which will replace the leisurelv 'Ghan' on the 771-mile stretch of narrow-gauge line between Port Augusta and Alice Springs was inaugurated on June 12th. Mrs. McLeay, wife of the Minister for Shipping and Transport (Senator McLeay) opened the service and named the first diesel the George McLeay after her husband. About 100 guests from Adelaide, entertained at a buffet luncheon at the railway station, were received by Senator McLeay and the Commonwealth Railways Commissioner (Mr. P. J. Hannaberry). The guests were taken on a 104-mile trial round trip using NSU 51 on standard gauge bogies between Port Augusta and Kookaloo. The stock included Special Service Car No.44, Budd Cars CB.1 & CB.2, first class sleeping cars AR.53, AR.71, AR.72 and power van HRGA.096. A dinner was held later that night to celebrate the opening of the service. Mr. Hannaberry proposed the toast 'The Diesel Builders.' The Managing Director of Sulzer Bros. (London) Ltd. (Mr. R. M. Atkinson), who travelled from England for the opening, responded. He was supported by Mr. T. R. Scales on behalf of the Birmingham Railway Carriage and Wagon Co. Ltd.

June 24th - 26th 1954

NSU51 & NSU52 worked the first diesel hauled northbound Ghan from Port Augusta on June 24th 1954. Departure from Quorn was 203 minutes late due to a minor derailment. However on the 453 mile journey to Oodnadatta 189 minutes were recovered. The on-time arrival at Alice Springs at 12.23pm June 26th had been crafted by halting the train south of Alice Springs for about an hour. The arrival was greeted by many people including the Prime Minister Menzies. The southbound departure occurred on June 28th at 4.30pm, 210 minutes after the scheduled departured, but arrival at Quorn was at 9.37am, 17 minutes ahead of schedule. Although both steam and diesel locomotives were resticted to 30mph, it was expected that eight hours would be cut from both the north and soutnbound journies.

July 9th 1954

NSU 53 & NSU 54 were unloaded from the 'Clan MacDonald' at Port Adelaide on July 9th.

Shortly after delivery NSU 54 worked on the standard gauge between Port Pirie & Port Augusta.

NSU 51 was named George McLeay on August 12th 1954, working a round trip to Bookaloo.

From the introduction of the first NSU Class locomotives in 1954 through to May 26th 1956, the total miles accumulated by the entire fleet was 1,411,645 miles at an average operational cost of 52.5pence per locomotive mile. Heavy repairs to the NSU Class were carried out at the Port Augusta workshops.

The NSU's initially worked the full Central Australia Railway (CAR) from Port Augusta to Alice Springs. A power station at Port Augusta provided much coal traffic from the coalfields in the Marree area, creating demanding work for the NSU's. Such was the level of traffic that in 1957 a new standard gauge route was laid between Port Augusta & Marree. This new alignment avoided the scenic Pichi Richi pass. The break of gauge point would now be Marree with the narrow gauge section remaining in place from Marree to Alice Springs. If used the spare standard gauge bogies required about fours hours to be fitted to the BRCW locomotives.

Following the successful operation of the NSU class, the maximum train loads were increased from 375 tons to 530 tons.

Eleven NSUs covered the Marree - Alice Springs line, and from 1958 to 1960 one was retained at Port Augusta to handle the barytes traffic on the Hawker line, the end of the truncated narrow gauge line to Marree. After 1961 it proved cheaper to use the South Australian Railways locomotive (available at Quorn)

NSU 63 & 64 were sent to Darwin in 1956. These locomotives assisted with the heavy traffic volumes left over from World War Two, initially covered by the transfer of many vacuum braked Western Australia Locomotives & wagons, later supplanted by post WW2 built stock. They also worked a weekly train to Larrimah & Katherine. In the latter years this traffic was mostly containers and trailers on flat wagons, which looked most precarious on the narrow gauge track! NSU 63 & 64 continued to provide all the motive power for the North Australia Railway until 1967. During November 1967 NSU 63 returned south to the Central Australian Railway following a major engine failure. After repairs NSU 63 remained operating on the CAR and was involved in its dismantling after the standard gauge reached Alice Springs in 1980. For the 50th anniversary of the bombing of Darwin the shell of NSU 63 returned north for display at Wishart Siding during 1992. NSU 63 was later moved to the Adelaide River Heritage Railway station site in October 2002.

By the end of 1956 the NSU class had aggregated over 1.5 million miles at an average operating cost of 52.5d per locomotive-mile. These operating costs had allowed the owners to recoup the original purchase price in less than three years.

During the 1950s stone traffic, in air braked hoppers was a staple traffic for a new RAAF airfield at ??.

The NSUs returned to the Quorn & Wilmington lines in 1980 with 53 & 58 working the goods and block grain trains. They were later joined by 52 & 56 and several NT's. These branches had remained narrow gauge long after the Broken Hill - Port Pirie line had converted to standard gauge. 58 was probably the last NSU in traffic, operating at least into 1988.

Out of the factory & across the ocean........

Seen here are the first two NSU's BRCW's in the process of being shipped between the United Kingdom & Australia. The placard on the diesel references shipment to Port Adelaide, the location of these views is believed to be Liverpool. The lower view comes from publicity material from 1954.

........... Into the Desert

And out to pasture

When the standard gauge line opened late in 1980 the original narrow gauge route immediately lost its reason for being. Deferred maintenance had taken its toll on the permanent way. During 1982 - 1983 the dismantling of the line commenced with Oodnadatta being the break point, separate crews working north or south to remove the rails. For the southern section through to Marree two NSU Class locomotives, NSU55 & NSU56 were used by Goss Brothers. Roberts Construction was responsible for removal of the route north of Oodnadatta.

The dismantling trains comprised two sets of flat wagons, a crew wagon and a locomotive. The rake of wagons were equipped with a track mounted on each side which allowed a converted digger to travel the whole length of the wagons, and which, in conjuction with a fixed winch was used to drag the salvaged rail lengths onto the wagons. The rails had been separated from the sleepers by a pair of metal wedges attached to the last wagon which tore the track from the sleepers as power was applied to the locomotive at the other end of the train. When a section of rail the length of the wagons had been ripped from the sleepers the workman would cut the rail and then use the digger/winch combination to drag the rails onto the wagons.

When the wagons were fully loaded a second locomotive took the recovered rails to Marree, where they were stockpiled pending transfer to standard gauge trains for movement south. Generally the two locomotives kept to their respective duties, though on occasion the locomotive from the dismantling train would take the salvaged rails on to Marree.

Once the dismantlers had reached Marree they continued their recovery efforts by removing the standard gauge line as far as Leigh Creek where the line remained in use by coal trains destined for the power station at Port Augusta. For whatever reason the dismantlers left a quantity of trackwork in place at Marree.

For the NSU Class locomotives at the southern end of the line Marree would become their resting place, mostly as decaying museum pieces.

![]()

Pichi Richi Railway, October 2006

On my Australia adventure during August 2006 I had stayed for several days in the Adelaide area and paid a visit to the Pichi Richi Railway at Quorn, this was on a winter's weekday so not surprisingly all was very quiet and the Workshop area was closed. Some might have considered this a wasted drive from Adelaide but we were tourists so 'nothing ventured, nothing gained' and we got to see a little more of Australia!

However shortly after my return to the USA the following text and pictures came from Gordon Byles announcing a unique event (so far!) on the Pichi Richi & perhaps best told in his words -

Pichi Richi Railway has just recorded a "FIRST"!!!

We have, for the first time, double headed our two SULZER powered locos on a passenger service.

This only occurred as the result of a number of events:

1. A windy day during drought conditions and temperatures in the high thirties on October 4th 2006 saw a decision made due to fire risk to cancel the steam hauling of our Afghan Express on the return trip to Port Augusta (PA). Instead, it was hauled by "NSU52". This left us with no steam locos available at PA to haul Saturday's Afghan Express.

2. Saturday's roster included two train services: The Pichi Richi Explorer (From Quorn to Woolshed Flat and return) and The Afghan Express (From PA to Quorn and return). This included combining the two trains at Woolshed Flat as a double headed train for the journey to Quorn before the Afghan Express returned to PA.

3. It was decided to use steam loco "NM25" to haul the Exporer to Woolshed Flat, lead the double header to Quorn and haul the Express back to PA. This would give us the desired situation of having our Commonwealth Railways loco stabled and ready to haul our Commonwealth Railways consist at PA.

4. Less than an hour before departure "NM25" was failed due to a severe leak from the boiler blowdown valve leaving no time to prepare another steam loco to haul the Explorer.

5. "NT76" was then pressed into service instead of "NM25" with steam loco "W22" being prepared for service for the Return journey to PA

This gave us the wonderful experience of hearing SULZERS in STEREO!!!!!!!

Thanks Gordon for the views and the events leading up to it.

![]()

|

Map of the narrow gauge rail - road - rail route from Port Augusta to Darwin Route as at the arrival of the NSU Class diesels

|

The presence of the large coal mine at Leigh Creek (near Copley) which supplied power stations in the Port Augusta area led to the narrow gauge line from Stirling North (Port Augusta) to Leigh Creek being converted to standard gauge during 1957 in order to better handle the increasing coal traffic. During 1961 this line carried over 1.2 million tons of coal. Following this the standard gauge was eventually pushed through to Marree allowing through standard gauge service from Adelaide to Marree, which then became the change of gauge point. The southern end of the narrow gauge route now ran only from Port Augusta to Hawker (66 miles) whilst from Marree to Alice Springs (540 miles) the narrow gauge remained unchanged. In April 1961 an air-conditioned standard gauge passenger train with lounge and dining car was converted to narrow gauge and proved vey popular on the Marree - Alice Springs route. The introduction of an a la carte meal service at the same time also proved popular and helped increase passenger loadings.

During 1962 tests were carried out with concrete sleepers designed to allow conversion of the track from narrow gauge to standard gauge. Tests were conducted on the Trans-Australian route and the Stirling North - Marree line.

In October 1980 the standard gauge rail was extended through to Alice Springs, connecting with the Trans-Australian Railway at Tarcoola. This original narrow gauge route had been built to connect with the known sources of water and was susceptible to flooding and drifting sand. The replacement standard gauge route was built to avoid these difficulties. It also bypassed Marree, which not only lost its importance as the change of gauge point, but eventually its presence on the rail network.

The opening of this new standard gauge route was the major factor in the demise of the tired & aging narrow gauge route and its work worn NSU Class locomotives.

Finke River crossing

The Finke River follows a NW - SE course, its source is west of Alice Springs and runs towards Lake Eyre, though only in very wet years does it join up with the waters of the Macumba to actually reach Lake Eyre. Which is perhaps a good thing because the narrow gauge line crossed the Finke River, as shown in the view below. Originally the track bed was laid on a low level formation across the river bottom, but due to the consequences of damage and delays caused when the river did run with any volume a low concrete bridge was constructed in about 1961. In the view below an NSU powered train uses the original formation, with the new bridge in the background.

The Alice Springs - Birdum gap

The 882 mile standard gauge rail gap between Alice Springs, Birdum & Darwin saw construction of the standard gauge rail line begin during 2000, with completion effected during 2003. On Sunday February 1st 2004 the first through passenger train between Adelaide & Darwin departed Adelaide at 12.10pm and arrived Darwin on February 3rd at 4.30pm. The special 43 coach train was hauled by NR109 & NR74 for its historic 1,851 mile journey. The NR Class locomotives were built during 1996/1997 in Australia utilising GE Dash-9 technology, the 16 cylinder power units being equipped with a variable horsepower feature - ranging from 2,850hp to 4,020hp. Fuel capacity is 12,500 litres, axle load 22 tonnes with a total locomotive weight of 132 tonnes. The aforementioned statistics are a world away from those imposed on the NSU Class approximately four decades earlier.

![]()

Other Australian Sulzers:

Commonwealth Railways NT Class

![]()

The link below points to a YouTube page which features a variety of railways including a video clip showing the method used to dismantle the southern part of the narrow gauge line. The clip features one of the NSU class locomotives, and if you listen carefully the rhythmic beat of the Sulzer six cylinder engine can be heard......enjoy

![]()

![]()

Over the hills and far away.........to Broken Hill, NSW.

The narrow gauge NSU & NT diesel electric locomotives were the only Sulzer powered locomotives to operate in Australia. However there were other types of installations operating Sulzer diesels in and around Australia. 284 kilometers east of Peterborough SA is the mining town of Broken Hill NSW which in the early 1930's become the home of a very large power generating plant.

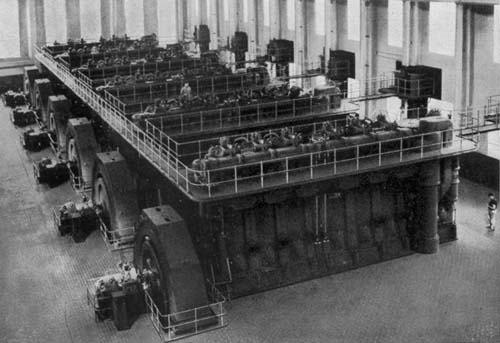

The discovery of the silver-lead-zinc mineral deposits in the area around Broken Hill, New South Wales in the 1880's saw the arrival of miners to work these deposits. During May 1908 two seven inch Sulzer turbine pumps were brought online at the new mill of the South mine. By the 1920's there were nine mines working the 'Line of Lode' with most using steam to power generators, with the electricity used in all areas of the mine operations. Like many of the steam railway operations in parts of Australia the mines also suffered from a shortage of water and the lack of local fuel made the steam generation expensive. To overcome this serious problem a new, centralised powerhouse was proposed in 1927, with an electrical output sufficient to handle all the electrical & compressed air needs of the mines. The cost of this electricty to the mines was at a cheaper rate than they could achieve with their own varied and aging installations.

The plant was originally ordered by the Australian Ore & Metal Co Pty Ltd but was later transferred to the Western New South Wales Electric Power Pty Ltd which would oversee the construction and operation of the plant, with Sulzer Brothers being one of the successful bidders. Six two-cycle engines, each developing 2,900hp were direct coupled to British Thomson-Houston, Rugby built 2,500 kva flywheel generators producing three-phase current of 40 periods and 6,900 volts. Additionally there were four Mirrlees, Bickerton & Day diesel engine driven compressor sets, each of 1,230hp, for supplying compressed air. The switchgear and electrical accessories were contracted to the Australian General Electric Comany, Melbourne.

During November 1930 the first engine and generators arrived at Broken Hill, having been shipped through Port Pirie. Their erection was under the supervision of Messrs J Treichler, chief erector for Sulzer Bros, Switzerland & his assistant J Mueller. The erection of the first engine would take about four months. The other engines would arrive at monthly intervals, with the second engine expected to arrive by the end of November 1930.

On July 18th 1931 the plant took over the continuous electrical load of the mines of the North Broken Hill Ltd, Broken Hill South Ltd, Broken Hill Ltd and Zinc Corporation Ltd. No serious incidents were reported during the first six weeks of operation. After installation a continuous trial of 20 days was successfully completed. Normal output would amount to 22,300hp, but with the ability to run at 20% overlead for short periods, thus providing a maximum output of 27,800hp.

When the Broken Hill plant came online it replaced the power station in Shanghai, China as the world's largest diesel engined power station.

A view of the six Sulzer engines in Station A. These were of the 6Z65 crosshead-type two stroke, each of 2,900bhp at 160rpm, 650mm bore & 880mm stroke. They were originally built with blast injection but were later converted to airless injection during the 1940s & 1950s.

In 1938 a seventh Sulzer engine was added, being a 6ZD65 crosshead-type two stroke, producing 3,200bhp at 160rpm. This engine had the same bore & stroke of the earlier 6Z65 type, but was equipped from new with airless injection.

Increased growth of the mines following World War II led to a major expansion for the Central Power Station, at a proposed cost of £2 million. The output of the existing station was already the largest in the Southern Hemisphere, with completion of the expansion in 1951 it would rank as one of the largest in the world. The new facility, known as Station B would be a replica of the existing Station A. By the summer of 1949 work on Station B and its powerhouse was sufficiently progressed to permit the installation of the first of the four diesel engines and air compressors. These would allow an additional 14,000 cubic feet per minute for use by the mines. Four substantial concrete foundations had been poured, two for the air compressor sets and one for a 3,000kW diesel generator set. Received from England & Switzerland during June 1949 were 500 tons of machinery, including one of the Sulzer engines, weighing 300 tons, from Switzerland and a 3,000kW alternator from British Thompson Houston. With the arrival of this machinery it was anticipated that a trial run would take place in July 1949. The second two would be received during May/June 1950, with the last shipped from Switzerland late in 1950.

Other work included three cooling towers, a 16 inch compressed air pipeline to the Zinc Corporation and N.B.H.C. mine, a workshop for the A & B Stations, switch room and oil treatment plant. For the employees a change-house and mess facilities were added. When completed the existing capacity of the Central Power Station provided by the Sulzer engines would increase from 20,600bhp to 39,100bhp. Total output for Station A would be 15,800 kW electric power and 4,000 kW air power, Station B 12,000 kW electric power and 2,000 kW air power.

On Monday March 6th 1950 the first of the new engine/generator sets had a satisfactory fifteen minute trial run and was expected to be in regular service by the end of March. The complete weight of the unit was about 300 tons, the alternator weighed 43 tons, the crankshaft 20 tons, the crankcase 27 tons, the cylinder cover 1.5 tons and the connecting rod with top and end bearings weighing about 1.5 tons. A second machine was being readied for service.

The engines supplied during this major construction period were:

1947 - one Sulzer 5TPF48 trunk-piston-type two-stroke of 1,450bhp at 218rpm

1949 - three Sulzer 6SF72 crosshead-type two-stroke, each of 4,150bhp at 185rpm.

During 1953 it was reported that four new engines were ordered from Sulzer Brothers to replace existing engines at the facility. These were part of the installation of three new air compressors, and were to replace the original Mirlees units located at Station A. Work on the new installation at Broken Hill was expected to commence during June 1954. Two of the engines arrived at Broken Hill during September 1953, the others were shipped from Winterthur during October 1953, with arrival at Broken Hill expected during December 1953.

These improvements utilised a Sulzer 6SF72 crosshead-type two-stroke of 4,150bhp at 185rpm and seven smaller Sulzer 4T48 trunk-piston-type two-stroke, each of 1,200bhp at 160 to 218rpm. The addition of these engines brought the total output of Sulzer engines at the facility to 47,050bhp.

By 1984 these nineteen Sulzer engines had accumulated 2,450,213 running hours with the longest running engine having more than 255,000 running hours!

In 1986 a new 40 megawatt generating station connected to the 220V was built at Broken Hill to replace the two earlier plants. Once the new plant was on line the older plants were closed and dismantled.

***************************************

Brief summary of engines:

19 engines with a combined site rating of 47050 bhp, comprising:

Central Power Station: six Sulzer engines installed in 1931, one added in 1938

'B' Station: 12 Sulzer engines installed 1939--1953.

The engines installed were, with site ratings:

1931 --- 6 x Sulzer 6Z65 crosshead-type two-stroke, each 2900 bhp at 160 rpm

1938 --- 1 x Sulzer 6ZD65 crosshead-type two-stroke, 3200 bhp at 160 rpm

1947 --- 1 x Sulzer 5TPF48 trunk-piston-type two-stroke, 1450 bhp at 218 rpm

1949 --- 3 x Sulzer 6SF72 crosshead-type two-stroke, each 4150 bhp at 185 rpm

1954 --- 1 x Sulzer 6SF72 crosshead-type two-stroke, 4150 bhp at 185 rpm

Plus 7 x Sulzer 4T48 trunk-piston-type two-stroke, each 1200 bhp at 160--218 rpm

The 'A' station had the seven Sulzer Z65 & ZD65 engines driving generators plus four Mirrlees engines driving air compressors. The other engines listed above were in 'B' station some driving generators and some driving air compressors. In one of the stations there were also a couple of Crossley-Premier engines driving compressors.

The Sulzer Z65 & ZD65 engines were of 650 mm bore & 880 mm stroke. The Sulzer ZD65 was built with airless fuel injection. The Sulzer Z65 engines were originally with blast injection but in the 1940s & 1950s were converted to airless injection.

The Sulzer T48 engines were of 480 mm bore & 700 mm stroke.

****************************************

![]()

Resources:

Sulzer Technical Review, November 4th 1929

Sulzer Technical Review, Special Number 1933

Railway Gazette, Overseas Railway Edition, 1954.

Railway Transportation, July & August 1954.

Railway Gazette, Overseas Railway Edition, 1956 (including map above).

Railway Gazette, Overseas Railway Edition, 1962

Gas & Oil Power, January 1934, pp 6-11

Australia Trove Resource for digitised newspapers and other resources

Information regarding the dismantling of the line: Graeme Reid.

Page added March 18th 2003

Page last updated September 26th 2020.