|

armstrong whitworth locomotive

Armstrong Whitworth Locomotives

& Railcars in the United Kingdom,

Powered by Armstrong-Sulzer engines

Powered by Armstrong-Sulzer engines

The Armstrong Whitworth Company was the product of Victorian era entrepreneurs using their ingenuity & problem solving skills coupled to the ever-growing engineering advancements of the Industrial Revolution.

William George Armstrong, born Newcastle upon Tyne in November 1810 finished his early education by becoming articled to a firm of solicitors. After becoming a partner and a good friend of the owner Armstrong's free time was spent exploring the world of mechanics, particularly the use of waterpower to drive machinery. In April 1847 with financing from close friends land was leased at Elswick, a factory constructed, crane building being the principal activity, the profits from which financed much of the research into other fields. Bridges and their opening mechanisms followed, contracts being received from I K Brunel no less.

Included in the varied research was the invention of the breech loading gun - Armstrong received his knighthood in return for surrendering the patents to the government. The Elswick factory workforce branched out further into the construction of ships, locomotives and armaments.

Joseph Whitworth was born in Stockport in 1804, apprenticing as a mechanic at an Ambergate cotton mill. Further training followed in London & Manchester with a strong desire to improve and enhance the existing mill related technology. His dedication and attention to detail led to the production of precision instruments and the machines & tools required to create them. Whitworth's claim to fame was the 'Whitworth thread' - the mass production of taps & dies, allowing the supply worldwide of standardised nuts & bolts. And as Armstrong's industrial facilities increased its output of items so Whitworth's Manchester area factories expanded their production into many products, including guns.

In 1887 Whitworth died, a multi-millionaire in today's terms, his empire was sold to Armstrong and the company renamed the Sir W.G. Armstrong Whitworth & Co Ltd. Lord Armstrong was also a very wealthy man, in 1894 he purchased Bamburgh Castle, having the majority of it rebuilt. He died in 1900 whilst the castle's restoration continued.

Further amalgamation occurred in 1919 with the Siddeley Deasey Company, and in 1927 with Vickers, when the greater part of the Armstrong Whitworth company became Vickers Armstrong.

And of course in September 1919 Armstrong Whitworth became a Sulzer diesel engine licensee.

During 1929 the board of Armstrong Whitworth approved the decision to enter the field of diesel rail traction and obtained a license from Sulzer Brothers for the use of their engines in these rail vehicles.

|

| Owner |

Engine Model |

Builder/Wheel Arrangement/Gauge |

Electrical Equipment |

Total |

Running Numbers |

| LNER, Armstrong - Shell Express (LMSR) |

6LV22 250hp Armstrong Sulzer |

Armstrong Whitworth, Newcastle 1931, 2-Bo, 4ft 8.5in |

GEC |

3 | 'Northumbrian', 'Tyneside Venturer' & 'Lady Hamilton' |

| Ribble Navigation / Preston Docks |

6LV22 250hp Armstrong Sulzer |

Armstrong Whitworth, Newcastle 1932, 0-6-0, 4ft 8.5in |

Laurence Scott & Electromotors |

1 | 'Duchess' (Works # D8) |

Armstrong Whitworth/LNER |

8LD28 800hp Armstrong Sulzer |

Armstrong Whitworth, Newcastle 1933, 1Co1, 4ft 8.5in |

Laurence Scott & Electromotors, Crompton Parkinson, Allen West |

1 | 'UniversaL' locomotive |

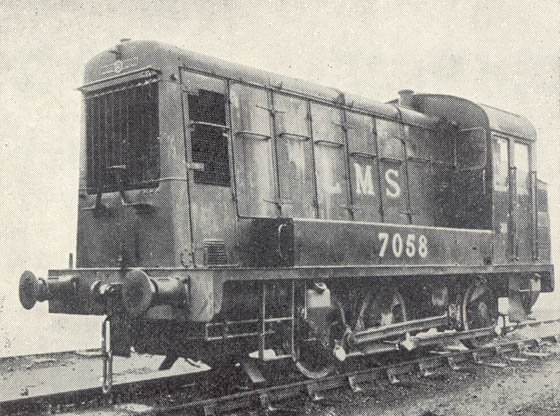

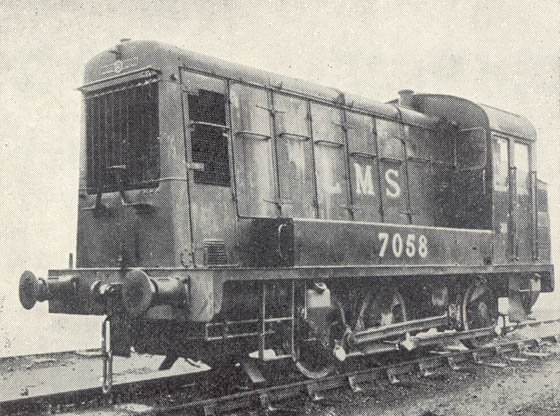

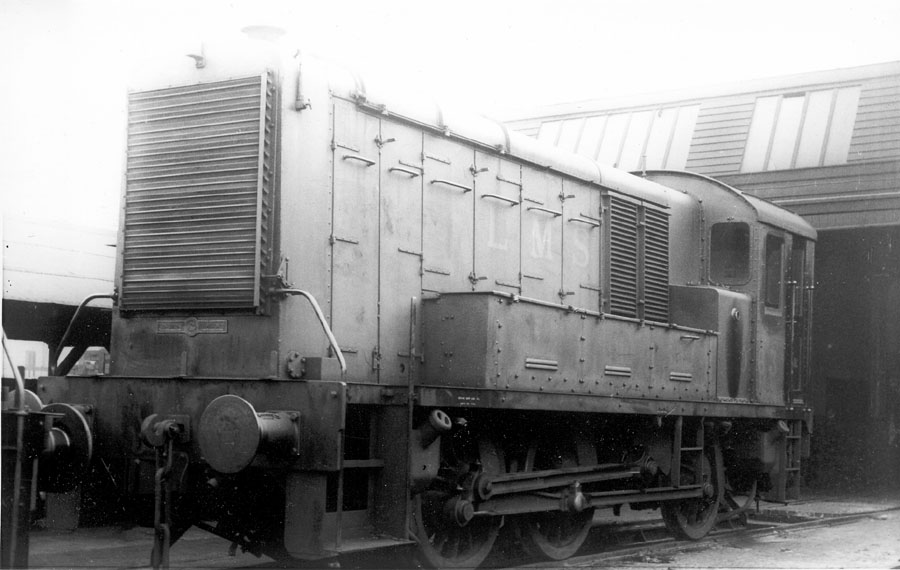

LMSR |

6LV22 250hp Armstrong Sulzer |

Armstrong Whitworth, Newcastle 1933, 0-6-0, 4ft 8.5in |

Laurence Scott & Electromotors |

1 | 7058 later 7408 (Works # D20) |

LMSR |

6LTD22 400hp |

Armstrong Whitworth, Newcastle 1935-1936, 0-6-0, 4ft 8.5in |

Crompton Parkinson |

10 | 7059 - 7068 (Works # D54 - D63) |

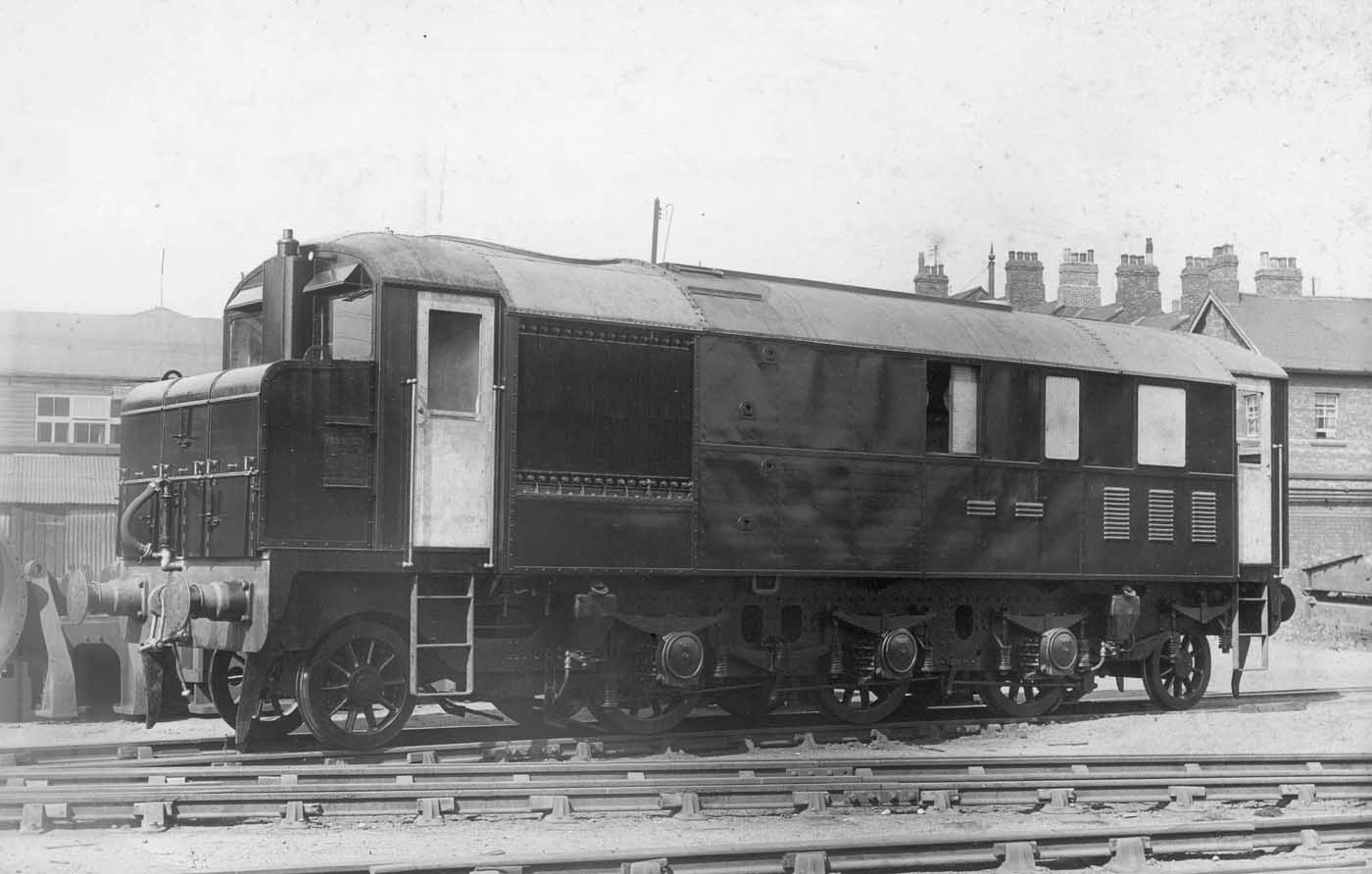

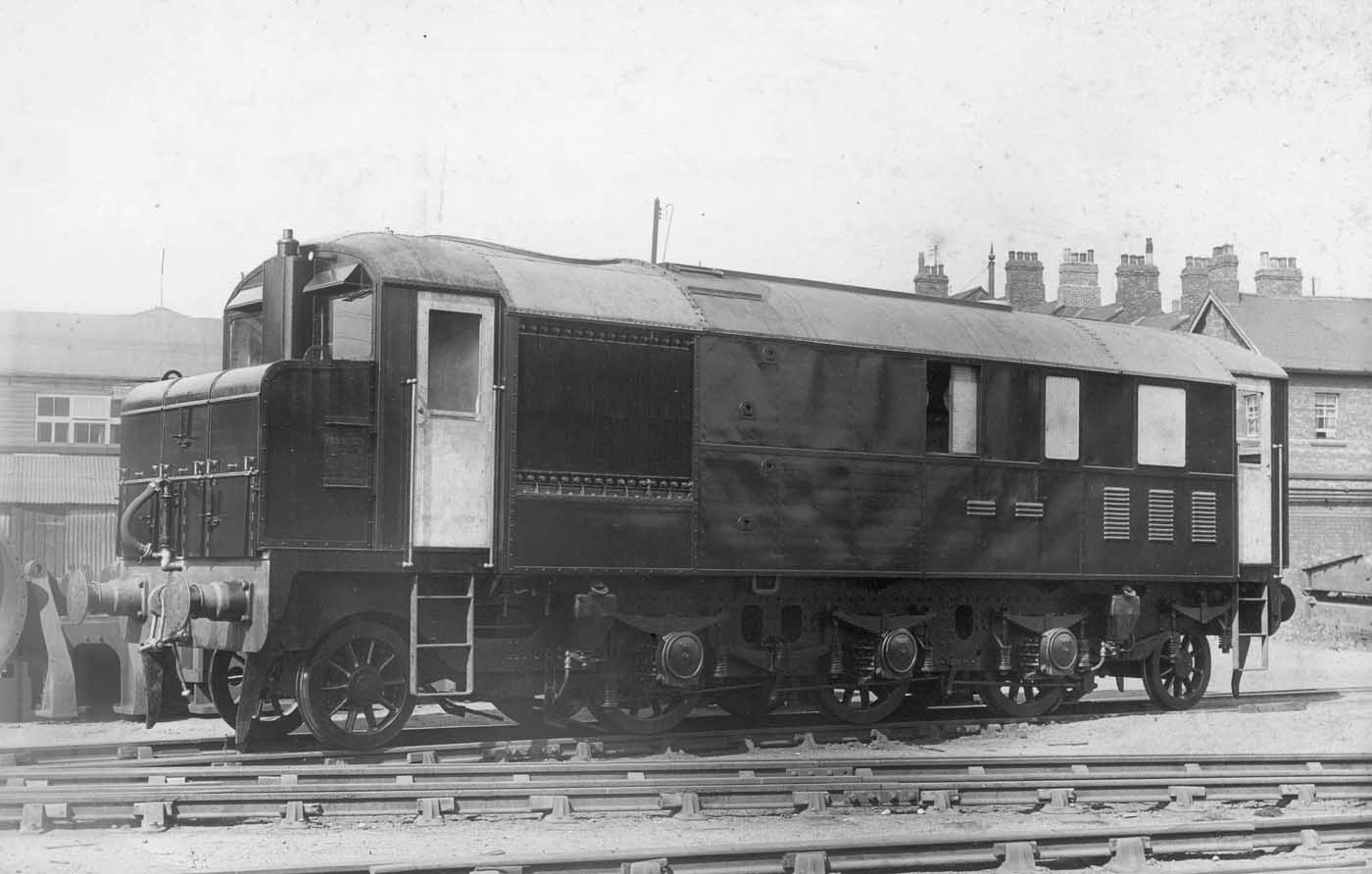

During early 1932 a prototype shunting locomotive was constructed by Armstrong Whitworth that perhaps could be considered the joint precursor (with English Electric demonstrator 7079 of 1936) of a vast fleet of 0-6-0 diesel electric shunters for British Railways.

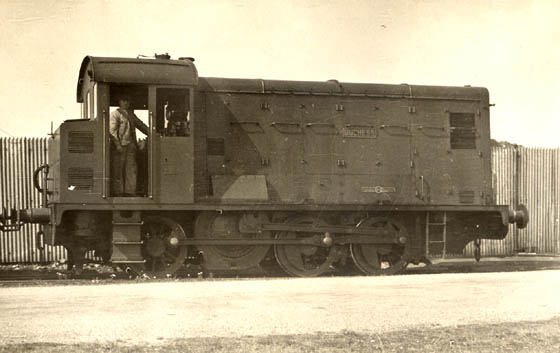

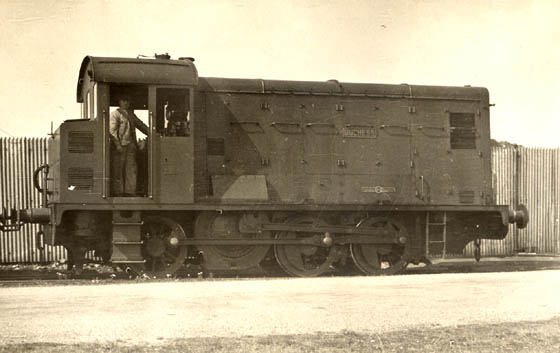

Photograph from a B&W postcard of unknown origin

A side view of Preston Docks 'Duchess' (AW works number D8, order number DT7), the fore-runner of the small fleet of AW shunters that worked on British Railways. All controls in the cab were duplicated, allowing operation from either side of the cab. The deadman's pedal was equipped with a time lag to allow the driver to move about the cab without having to stop the locomotive.

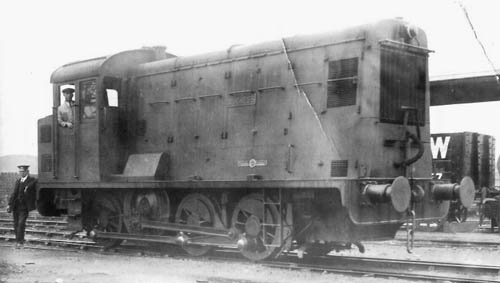

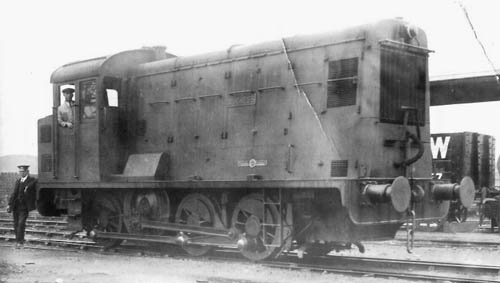

Photograph courtesy of 'Nasher' from Bath.

An early view of 'Duchess', judging by the style of clothing on the staff and the lettered wagons in the background. The locomotive would spend 34 years in service at Preston Docks. Its time there was not without its problems - in particular with the drive to the auxiliary generator and the radiator cooling fan, frequently leading to inconsistant charging of the starting batteries leading to flat batteries.

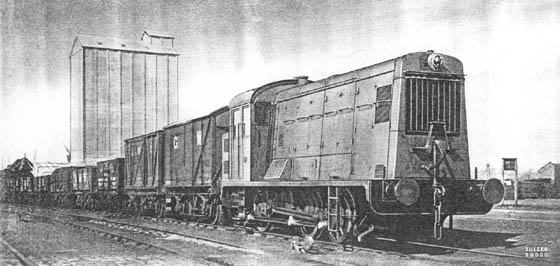

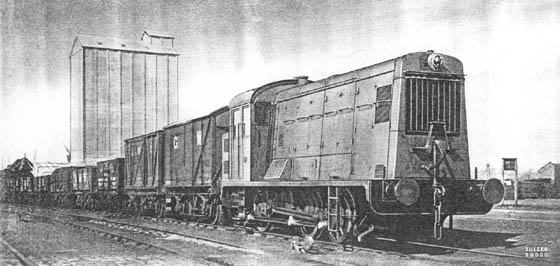

A view frequently used of 'Duchess' in advertising material by Sulzer, particularly in Diesel Railway Traction during 1944.

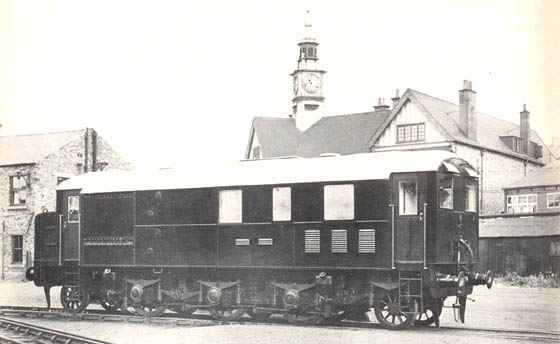

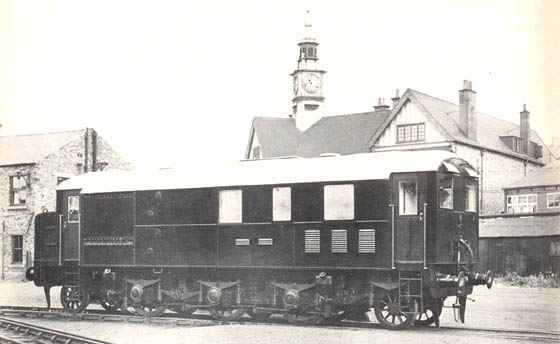

Another early view of the 1932 prototype demonstrator, sometimes used in promotional articles about the locomotive.

This locomotive was fitted with the same engine that went into the three heavyweight railcars produced just prior to this locomotive - a 250hp 6LV22 engine. The main generator and single traction motor were provided by Laurence Scott & Electromotors, the traction motor was frame mounted within the wheelbase using a jackshaft drive with rods to power the wheels. Length over buffers was 29ft, height 12ft 3in, width 8ft 6in, wheelbase 13ft and maximum tractive effort was 24,000lb.

Essentially the locomotive was built as a demonstrator, not having an immediate buyer, and spent much of 1932-1933 working at several LNER goods yards in the Newcastle area. Extensive tests were completed by Armstrong Whitworth prior to the handing over to the LNER on June 10th 1932 for testing in their Forth Goods yard. At the controls for a short time was the LNER CME Mr H N Gresley, who was impressed by the results. An agreement followed with the locomotive taking up shunting duties from July 11th 1932 at Forth marshalling yard, then in the yards at Blaydon & Heaton. Loads at the Forth Yard were upto forty wagons totalling 600 tons, whilst the Blaydon Yard with its gradients permitted a maximum load of 750 tons. After a month at Blaydon it moved to Heaton Yard. Here it was challenged by taking 800 ton loads up the 1 in 150 Benton Bank. Fuel consumption with this type of working was about 2.5 gallons per hour. Availability for this period was 98.5%, (for the engine it was 100%), the general availability being affected by a derailment and brake troubles. It was noted that although scheduled for three eight hour shifts six days a week, the locomotive actually spent just under one third of that time idling! The LNER trials ended on October 30th 1932.

Breakdown of the trials spent on the LNER:

Forth Yard: July 11th 1932 - July 24th 1932

Blaydon No.3 Pilot: July 25th 1932 - July 31st 1932

Blaydon No.2 Pilot: August 2nd 1932 - August 21st 1932

Heaton No.2 Pilot South: August 22nd 1932 - October 16th 1932

Heaton North: October 17th 1932 - October 30th 1932

After the LNER returned the shunter to Armstrong Whitworth it undertook other trials. These included two months spent on the Southern Region, at Bricklayers Arms, Eastleigh & Norwood Junction. Then followed trials on the Hartley Main Colliery Railway, Northumberland, which ended with the locomotive being hit by a loaded runaway ballast wagon which caused considerable damage to the cab. The locomotive returned to Scotswood for repairs. Further trials then followed at Lever Brothers, Port Sunlight and with Ribble Navigation at Preston Docks. The locomotive then returned to Scotswood, remaining there until March 1935 when it was purchased by Ribble Navigation. It was named 'Duchess' and worked alongside the company's steam shunters.

Its thirty four years in service saw very few changes to its appearance. At some point the vacuum brake pipes & hoses mounted on the buffer beams were removed.

It remained in service until 1969 when it was withdrawn following the arrival of new diesel shunters. Its livery at withdrawal was a faded apple green (?) for the cab & body. The buffer beam and frame rail were red, the area above the radiator was a faded black with rusty water stains. As late as March 1968 the 'Duchess' nameplate was still fitted as was the 'Armstrong Whitworth' plate.

Photograph courtesy P. Eckersley/collection of webmaster.

September 25th 1958 and the career of 'Duchess' has now reached its 26th year and still with another decade to go.

Photograph courtesy P. Eckersley/collection of webmaster.

Its May 8th 1967 and the career of 'Duchess' is drawing to a close. It is seen here in the Preston Docks complex.

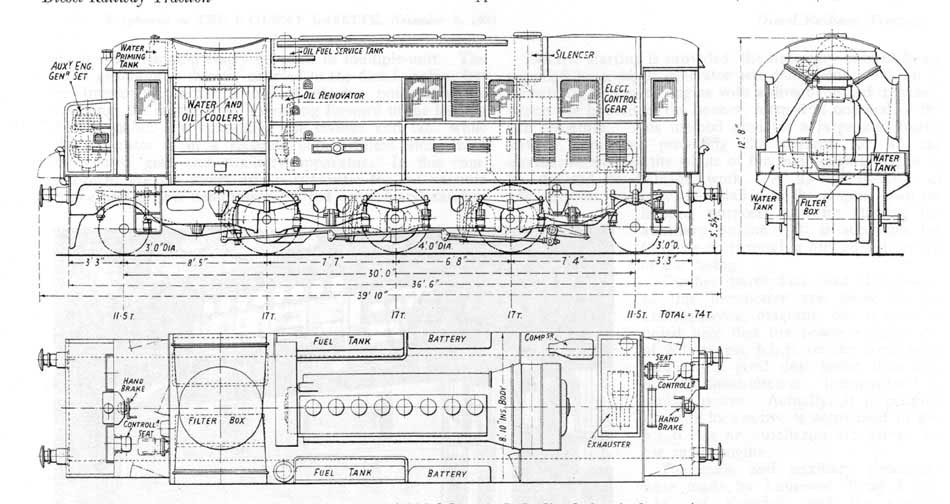

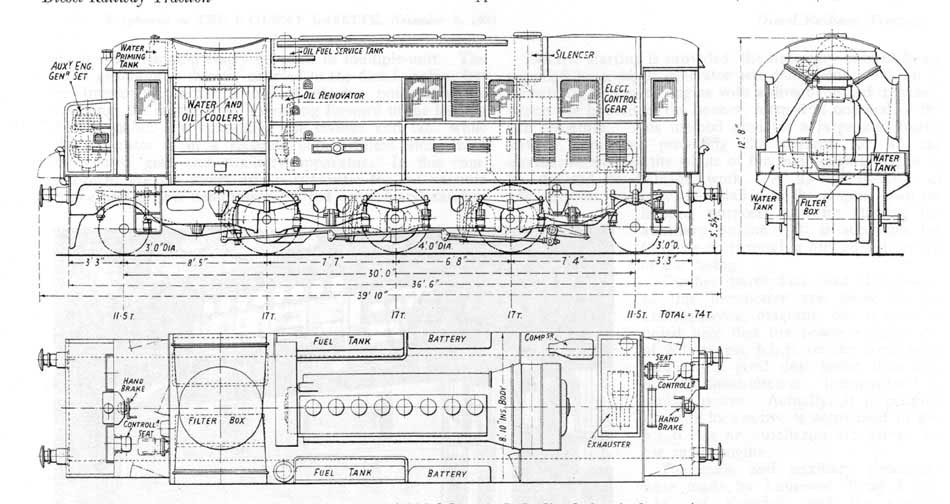

Armstrong Whitworth Order No.DT8, carrying No.D9 of 1933 would become the first mainline diesel locomotive to run in Great Britain.

Photograph courtesy Armstrong Whitworth/Diesel Railway Traction

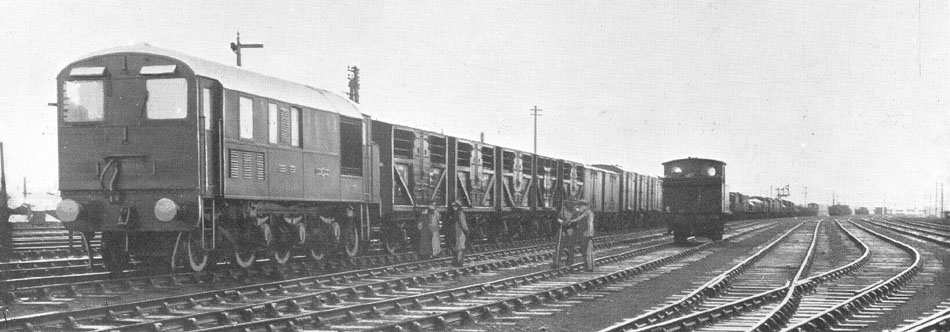

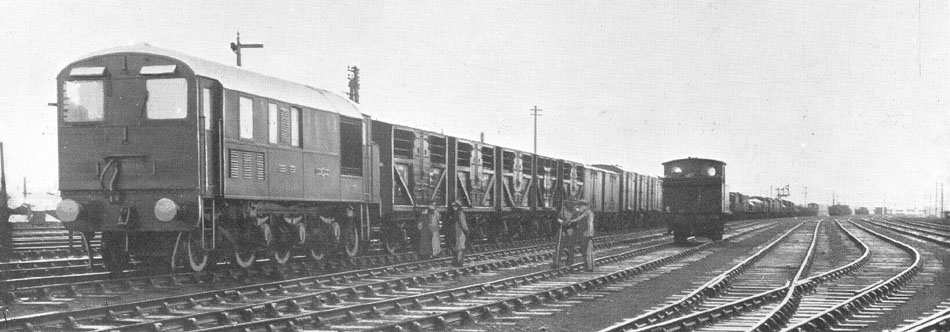

During 1933 Armstrong Whitworth Co. of Newcastle upon Tyne released for trials on the LNER a 1-Co-1 diesel electric locomotive. The 74 ton locomotive had been designed as a mixed traffic machine, with a maximum axle loading of 17 tons, a maximum starting tractive effort of 28,500lb and a maximum speed of 70mph. Although only one locomotive was built it was fitted with multiple unit working capability with the intention that two locomotives could be worked by one driver on goods trains up to 1,500 tons and 500 ton passenger trains up to 60mph on level track. A single unit was permitted to haul 800 ton freights or 260 ton passenger trains.

The 1-Co-1 wheel arrangement (2-6-2 'Prairie' steam classification) utilised 4 ft diameter driving wheels with Isothermos axle boxes with an equalised spring arrangement allowing useage over indifferent track. Sanding was provided on the two outside driving wheels with air supplied from a small compressor. Braking was by means of the automatic vacuum system, two large cylinders applied brake blocks to all the driving wheels.

The diesel engine was an Armstrong-Sulzer 8LD28 eight cylinder inline device, the cast cylinder block comprised of two four cylinder units carried on a steel welded crankcase. Attached to this was the main generator frame, the whole diesel-generator set was supported directly by the locomotive frame. The cylinder heads are seperate, housing the inlet & exhaust valves in cages for easy maintenance of the valve seats. The cylinder liners are of cast iron, of the wet type, with the pistons of forged aluminium.

The rated output was 800hp at 700rpm with a brake m.e.p. of 80lb per square inch. Full engine output was available between 6mph & 65mph. Normal full load fuel consumption was 0.40lb per hp hour, lubrication oil consumption was about one per cent of the fuel oil total. All output of the engine was available for traction, an 80hp Armstrong-Saurer model 6BXD auxiliary engine housed in the nose supplied all the auxiliary needs and obviated the need for a large and heavy set of batteries to start the main engine. Rather unusually the main engine carried no metal rocker covers, roll-back leather covers were used, held in place by spring fasteners. Two large side mounted radiators provided cooling for the water and lubricating oil, air being drawn through by a roof mounted fan. The fuel tanks and 24 cell batteries were mounted either side of the engine alongside the walls. Because of the fitting of the auxiliary engine descriptions of the locomotive give its horsepower as either 800 or 880.

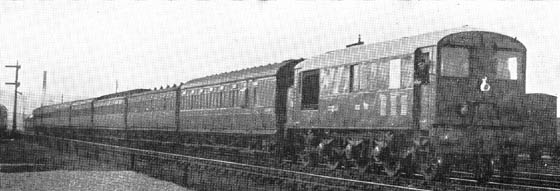

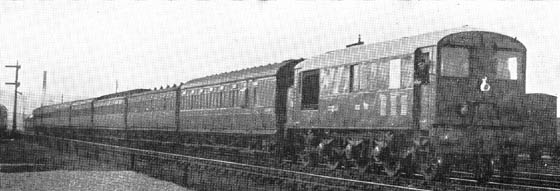

The Universal locomotive on test with passenger stock at Blaydon. For a short time the locomotive was used on passenger services between Newcastle & Carlisle.

The electric transmission was controlled by a regulator operated by an hydraulic servo motor permitting full output of the diesel engine from 6mph to 65mph. Although the Laurence, Scott & Electromotors main generator was directly coupled to the engine the bodywork was built up between the two so as to place the generator in a seperate enclosed space. This compartment also contained the control gear, compressor & exhauster. The three Crompton Parkinson Ltd self-ventilated axle-hung traction motors were equipped with roller bearings for the armatures and white metal lined pad lubricated suspension bearings on the axle. The control gear was supplied jointly by Laurence, Scott & Electromotors and Crompton Parkinson.

The locomotive had been built as a demonstrator and initial trials commenced on July 6th 1933, working between Newcastle & Alnmouth, additionally making several trips between Newcastle and Hexham. Further tests in 1933 were to be completed with goods trains of forty five & sixty wagons between Newcastle and Berwick & York. Passenger workings took place between Newcastle & Carlisle. Runs with empty coaching stock also took place between Newcastle & Tweedmouth. On June 7th 1934 the locomotive strayed slightly from its more familiar routes when it worked an eight coach Institute of Transport Congress return special between Leeds & Darlington. A short while later the locomotive suffered a crankcase explosion, returning to Scotswood for repairs. The repairs were not forthcoming with the locomotive, minus its engine stored in the yard, having accumulated 26,140 miles in its year of service. The locomotive was dismantled sometime during 1937, however its engine would be repaired and see further service.

Although this pioneer locomotive proved to be a deadend for its builder, a further two similar machines were built, intended hopefully for service in India, but in fact tested briefly in Ceylon and later purchased for use in Argentina.

Photograph courtesy J W Armstrong

AW's 800hp demonstrator spent some time testing on the LNER between Newcastle & York. It is seen here on an unknown date near Darlington.

Photograph courtesy Armstrong Whitworth.

The 8LD28 engine is lowered into the body of the 'Universal' locomotive. This was early days for the LD series engine, some 20 years later and now fitted with a pressure charger the LDA model would power the BR/Sulzer Type 2's, some of which spent many years at Gateshead and would travel the same routes used by the Universal locomotive and others produced by AW.

Photograph courtesy Armstrong Whitworth.

A lengthy goods train awaits departure from Blaydon. Tests on the ECML between York - Newcastle - Berwick involved goods trains of 45-60 wagons.

Photograph courtesy Armstrong Whitworth.

The 'bonnet' end of the locomotive leads with a set of passenger coaches at Alnmouth. Under the bonnet was the 80hp auxiliary Armstrong-Saurer engine. The locomotive trialled between Newcastle & Tweedmouth on empty coaching stock. One of it's early tests had been with a train of 17 coaches under the watchful eye of AW engineers and LNER railway officials including Nigel Gresley.

Photograph courtesy Armstrong Whitworth.

A view of the almost completed UL locomotive in Scotswood yard. Some parts still remain to be fitted whilst the roof and cab doors still require painting.

Elevations for the 'Universal' locomotive.

Photograph courtesy W Bryce Greenfield.

The AW locomotive on a freight train believed to be photographed somewhere near present day Tyne Yard, sometime during 1934.

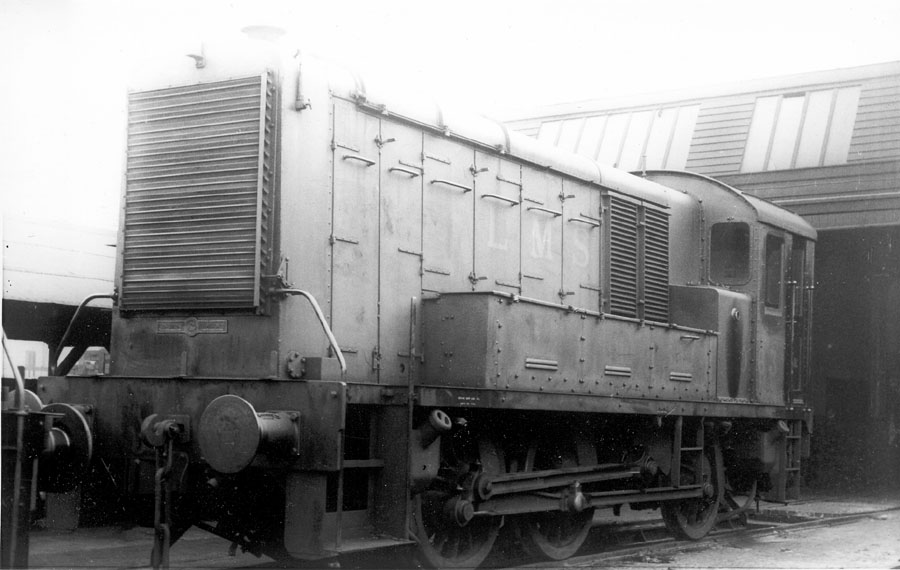

The decision made by the LMSR to test a variety of diesel shunters, including one of 250hp capacity led to Armstrong Whitworth building an 0-6-0 diesel electric shunter very similar to D8 during 1933. This machine carried the numbers 7408 & 7058 on the LMSR and was allocated the British Railways number 13000 in the post nationalisation re-numbering scheme, although it was broken up prior to carrying this number.

Allocated Works number D20 of 1933 it was fitted with a Armstrong Sulzer 6LV22 diesel engine, powering a Laurence Scott & Electromotors generator and single frame mounted, force ventilated traction motor. With the engine rated at 250hp at 775rpm with a maximum tractive effort of 24,000lb and a maximum speed of 30mph, this shunting locomotive clearly had the best characteristics that the LMSR were seeking when compared to the other locomotives tested. Most significant were its electric transmission, its heavier weight and a fuel capacity that would allow a week of shunting prior to refuelling. Its overall dimensions were similar to that of D8.

Of the nine diesel shunters ordered by the LMSR in 1933 (?) only the Armstrong Whitworth locomotive was a diesel-electric, all the others were diesel mechanical.

Photograph courtesy Diesel Railway Traction

As No.7408 and then 7058 the locomotive entered service on the LMSR during the middle of February 1934, working in the yards at Brent, Crewe, Beeston, Toton and Bescot. It was also borrowed by the War Dept, returning to the LMSR during 1943. Availability proved to be very good, in one year it averaged 22 hours per day in service, covering 9,200 miles. The locomotive survived until 1949, by which time its place was being taken by its offspring.

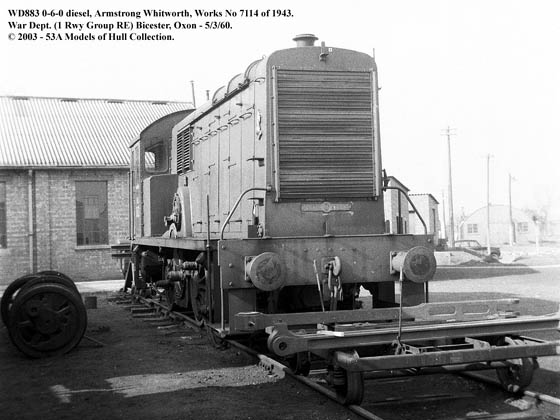

The success of the 7408/7058 led the LMSR to place an order for a further twenty locomotives, ten from Armstrong Whitworth and ten from English Electric - with the mechanical portions of these sub-contracted to Hawthorn Leslie. Interestingly in both cases the mechanical portions were constructed in the Newcastle area, however the Hawthorn Leslie machines were shipped to Preston for the installation of the power equipment. Armstrong Whitworth delivered their ten locomotives between May 1935 & November 1936.

These ten locomotives were enlarged versions of the two early 0-6-0 diesel electric shunters. The engine was similar to that in 7408, however the extra horsepower was obtained by increasing the speed by 100rpm and the mean effective pressure of the cylinders from 65 psi to 81psi. Lighter components were also incorporated wherever possible, assisted by the use of cast & welded construction techniques. Although their output was normally quoted as 350hp to match the English Electric machines, the fuel racks and governors could be set to allow operation of the engine at 400hp at 1,000rpm.

The single traction motor with double reduction gear drive again used a jackshaft drive to pass power the the wheels. This created an unequal spacing of the wheels creating a longer wheelbase than the Hawthorne Leslie units.

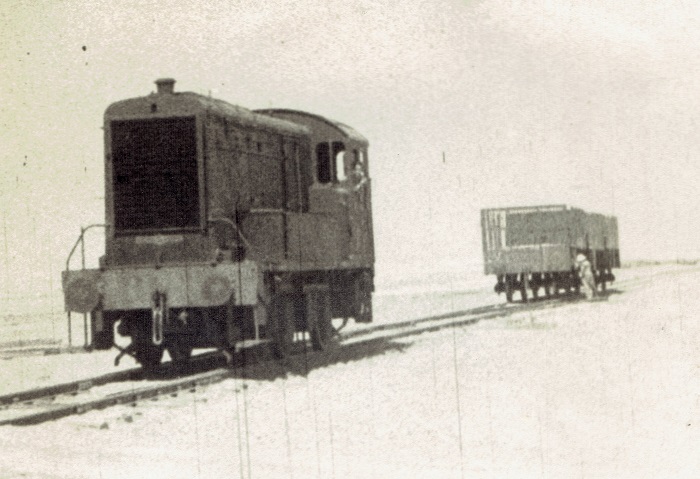

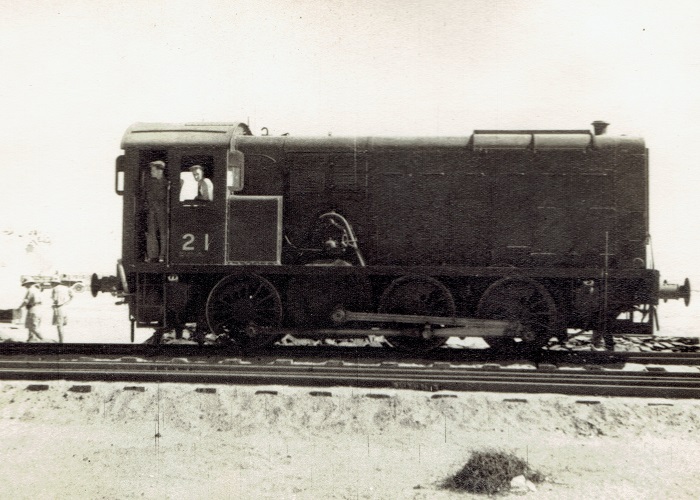

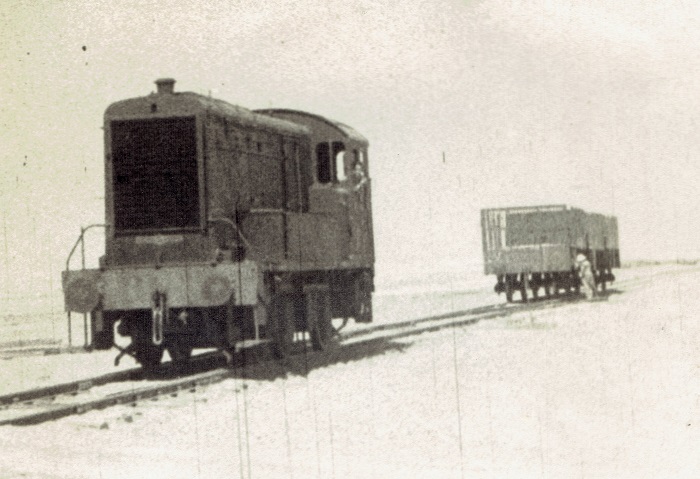

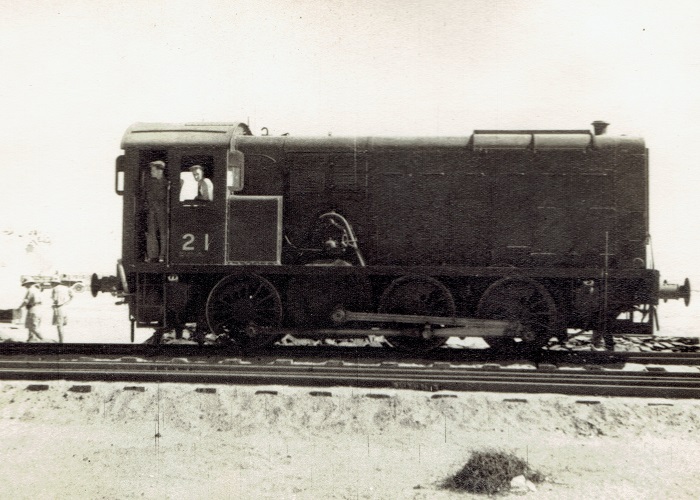

After completion and testing at Scotswood the locomotives were delivered to the LMSR at Carlisle for acceptance trials. In service they spent time at many LMSR yards including Carlisle, Crewe South & Willesden. All ten were taken over by the War Department with many seeing service overseas, particularly Suez and Europe. After the end of World War II most remained in service until the late 1960's.

Two views above courtesy Historical Railway Images on Flickr

Two views above of WD 21 (ex-LMSR 7066, later WD 70021), believed to be in Egypt, the photograph indicates 'Mex Junction', but uncertain where this is precisely.

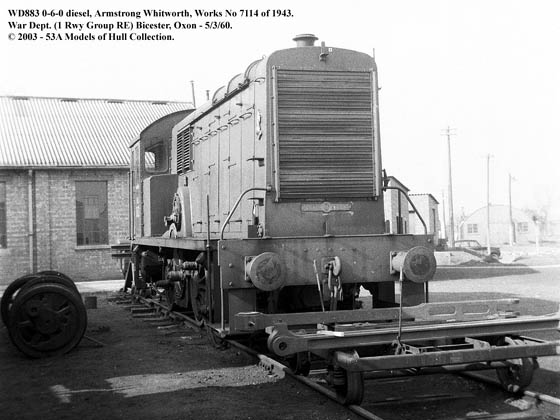

The above view shows the WD883 (former LMSR No.7063) from the driving cab end. (Photograph collection of webmaster)

With many thanks to John Turner for permission to use this view, click on any part of the picture to get a bigger view.

A fine view of WD 883 (previously LMS 7063 & WD70216) at Bicester on May 3rd 1960. Clearly visible is the tapered bonnet and the Armstrong Whitworth insignia on the front panel. The locomotive had received an overhaul during 1958. This locomotive ended its days at Hams Hall power station shunting coal wagons. It was broken up there in late 1967, just a stones throw from the Derby - Birmingham main line where a considerable amount of the freight and passenger traffic passed by with locomotives powered by the Sulzer 6 & 12 cylinder LDA28 engines.

The movement of WD 883 from Brackley (from E L Pitt or R Fenwick & Co.??) to Hams Hall took place under its own power on February 16/17th 1966. The Buckingham - Banbury line, which had been closed to all traffic in December 1963, was reopened temporarily to accommodate this move. The shunter ran from Brackley - Verney Junction - Blethcley, staying here overnight, then to Nuneaton - Stockingford - Whitacre Junction & Coleshill.

By April 1967 WD883 was noted stored out of use at CEGB Hams Hall.

| LMS 7059 - LMS 7068 |

| LMSR # | AW Works # |

Retired from LMSR |

WD # | Final Owner & # | Withdrawn/Broken Up |

| 7059 | D54 |

11/44 |

70213 | SNCB 230.001 | WD 3/58, BU ?? |

7060 | D55 |

12/42 |

70019 | WD 70019 | WD ?/45, BU by 1952 |

7061 | D56 |

11/44 |

70214 | SNCB 231.001 | WD 2/65, BU ?? |

7062 | D57 |

11/44 |

70215 | LKW Union WD 882 | working in 1975 |

7063 | D58 |

11/44 |

70216 | WD 883 | WD c.1967, BU late 1967 |

7064 | D59 |

11/44 |

70217 | SNCB 231.102 | WD 5/61, BU ?? |

7065 | D60 |

12/42 |

70020 | ESR 4022 | WD 1974, BU ?? |

7066 | D61 |

12/42 |

70021 | WD 70021 | WD c.1945, BU 1951 |

7067 | D62 |

11/44 |

70218 | SNCB 231.103 | WD 1/66, BU ?? |

7068 | D63 |

12/42 |

70022 | ESR 4021 | WD 1974, BU ?? |

ESR = Egyptian State Railways

LKW Union = LKW-Union, Import-Export, Dortmund, Germany.

SNCB = Societe Nationale de Chemins de Fer Belgique.

WD = War Department.

| Comparisons between 7408 and the ten production shunters |

| 7408/7058 |

7059 - 7068 |

| Transmission (Electric) | Laurence Scott & Electromotors |

Crompton Parkinson |

Weight | 40t 10cwt |

52t 0cwt |

Length over buffers | 28ft 10in |

31ft 4.5in |

Max width | 8ft 6.5in |

8ft 7in |

Wheelbase | 13ft 0in |

14ft 6in |

Wheel diameter | 3ft 6in |

4ft 3in |

Maximum Tractive Effort | 24,000lb |

34,000lb |

Maximum Speed | 30mph |

20mph |

Rated power of engine | 250hp at 775rpm |

350hp @ 875rpm |

Cylinder bore & stroke | 220mm x 280mm |

220mm x 280mm |

Fuel capacity | 570 gallons |

630 gallons |

Traction motor | One - force ventilated, six pole |

One - force ventilated, four pole |

Gearing | Single reduction, jackshaft 5.76 : 1 |

Double reduction, jackshaft 11.1 : 1 |

Photograph courtesy W L Good.

Willesden shed April 22nd 1934, LMS 7408 receives attention to its batteries and other bits and pieces.

Photograph courtesy W L Good.

Willesden shed April 18th 1937, LMS 7408 has now been renumbered LMS 7058 and keeps company with a number of other diesel electric shunting locomotives.

Photograph courtesy W L Good.

LMS 7063 at Crewe South September 19th 1937.

Photograph collection of webmaster.

A busy scene at E L Pitt's yard, Brackley, Northamptonshire on May 14th 1964. In the left background is the former LMS 7063. Its next move would be to Hams Hall power station, Coleshill.

As mentioned in the opening notes of this page, during 1929 the board of Armstrong Whitworth approved the decision to enter the field of diesel rail traction. Their first vehicles would be the three heavyweight railcars detailed below. Within the company and no doubt a significant influence in their construction was Donald Watkins. Mr Watkins had graduated as an Electrical Engineer in the 1920s and spent time in Switzerland, being taken on as a trainee by Brown Boveri and which included visits to the Sulzer Brothers Works in Winterthur. On returning to the United Kingdom in about 1929 Mr Watkins joined the fledgling Diesel Traction Department of Armstrong Whitworth. In 192 Mr Watkins was appointed Chief Electrical Engineer in the Diesel Traction Department and in 1934 the title of Scotswood Contract Manager was added to his responsibilities. Mr Watkins also grew to know the then current LNER CME Nigel Gresley, who took some interest in these new railway technologies.

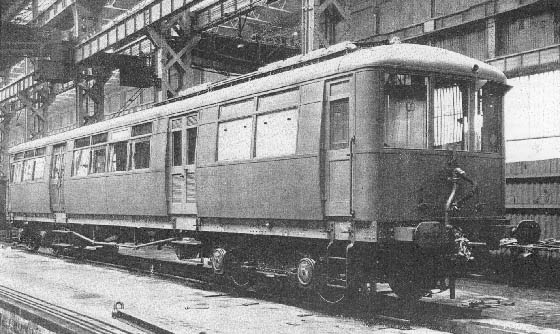

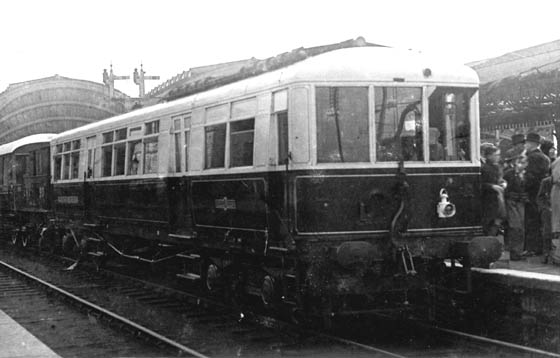

In 1931 the Diesel Department of Armstrong Whitworth began construction of its first venture: three heavy diesel electric railcars, which operated under the names of 'Tyneside Venturer', 'Lady Hamilton' & 'Northumbrian'. They were powered by an Armstrong-Sulzer six cylinder 250hp four stroke diesel engine coupled to GEC electrical equipment. The vehicles were 60 feet long with a cab at each end and a compartment for the engine. They weighed 42tons 10cwt, could carry sixty passengers and luggage at 65mph. The bodywork was provided by Craven Railway Carriage & Wagon Co of Sheffield. The body was of sheet steel panels riveted together. Operating costs were expected to be half those of a steam service of similar capacity.

As well as running singly the railcars could haul a trailer coach, and were flexible enough to allow all three to be combined with three trailer vehicles.

Tyneside Venturer, #25

'Tyneside Venturer', in a livery of dark blue and cream was the first car to be delivered from Scotswood, following trials in October/November 1931 it was made available for inspection by LNER officials on November 23rd 1931. A brief report in the Railway Gazette from November 27th 1931 gives information on trials carried out by 'Tyneside Venturer' in the Newcastle area. The trial was under the supervision of H. N. Gresley, CME of the LNER, P.D. Ionides, Vice-Chairman of Sir W G Armstrong Whitworth & Co (Engineers) Ltd. Others present were senior members of the LNER staff and a director from Armstrong Whitworth. The trial was made under normal service conditions from Newcastle Central to Blackhill, with nine stops being made. The scheduled journey time of forty five minutes was bettered by almost seven minutes. Operation of the railcar was by an LNER steam locomotive driver with only three hours training on the railcar!

The return journey was an express run made via Lanchester, Durham & Birtley which included a long gradient of 1 in 66. On level track the railcar attained a speed of 64mph. Favourable comment was made about the smooth running and the quietness of the railcar. Mr Gresley commented: 'The trial has been extremely successful, and I think that the car stood up to the severe test put to it very well'.

Following this success tests were carried out on January 21/22 1932 over the York - Malton - Whitby - Scarborough route. The railcar was put through its paces over this varying route which included the coastal section between Whitby & Scarborough with its stiff grades of 1 in 39 & 1 in 43. In all events the railcar performed admirably. Acceleration tests on the Scarborough - York route revealed:

0 to 20mph in 26 seconds

0 to 30mph in 46 seconds

0 to 40mph in 82 seconds

Fuel consumption averaged 5mpg, with 4mpg achieved on the gradients and 6mpg on level track.

On February 16th 1932 the railcar worked a demonstration run to Hexham in multiple with the recently completed and grey liveried 'Lady Hamilton', on the return journey the railcars stopped at the Scotswood Works to allow the party of railway officials from home and overseas to inspect items under construction.

On April 11th 1932 it entered regular passenger service in the Newcastle area. After six months it moved to handle services in the Middlesborough area. It was purchased by the LNER in November 1932, although not taken into stock until January 1933. In regular service it worked to Hexham, to Rowlands Gill & Lintz Green and on the North Wylam line. The railcar was in service for seventeen hours a day, just over half of which was scheduled running, the remainder idling. Daily mileage was just over 200 miles and average fuel consumption was a fraction over five miles per gallon. They were operated by a roster of a dozen LNER steam engine drivers, always with an Armstrong Whitworth representative alongside.

When the railcar moved to the Middlesborough area in October 1932 its operating statistics dropped slightly, working to Guisborough and sometimes Lofthus & Saltburn. The fuel consumption dropped to four miles per gallon due to the more heavily graded lines. Whilst operating from these two locations the mileage totalled 34,146, whilst total fuel consumed was 7,087 gallons. Mechanically the engine and electrical equipment were in good condition after thirty five weeks of intensive service in which period 100% availability had been achieved.

On November 24th 1932 'Tyneside Venturer' was purchased by the LNER for GBP7,500, it would keep its name and be numbered No.25. Its livery would be changed to green and cream late in 1934.

During the summer of 1933 the 'Tyneside Venturer' was employed by the LNER to run a daily excursion over the Yorkshire Moors, leaving Scarborough at 10am for Whitby, where lunch was taken, then returning along the coast route to Scarborough during the afternoon. This proved to be a popular outing, the railcar frequently having a trailer coach added to it to meet the demand. During the first six months of 1933 this railcar ran 22,000 miles over the heavily graded routes between Middlesborough, Saltburn, Whitby & Scarborough, including the 1 in 39 Ravenscar Bank - its regular duty once the summer season was over.

For a short period in 1935 the railcar was used in the Bradford/Keighley area.

'Tyneside Venturer' received Works visits in September 1934, April 1936 & October 1937, generally spending eight to twelve weeks in Works. It was taken out of service during April 1939 after sustaining minor collision damage at Middlesborough. Repairs were not forthcoming, having completed just in excess of 250,000 miles running.

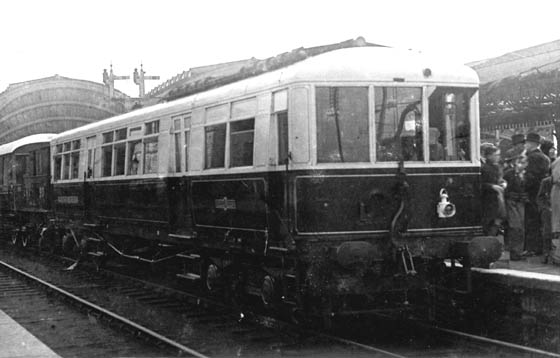

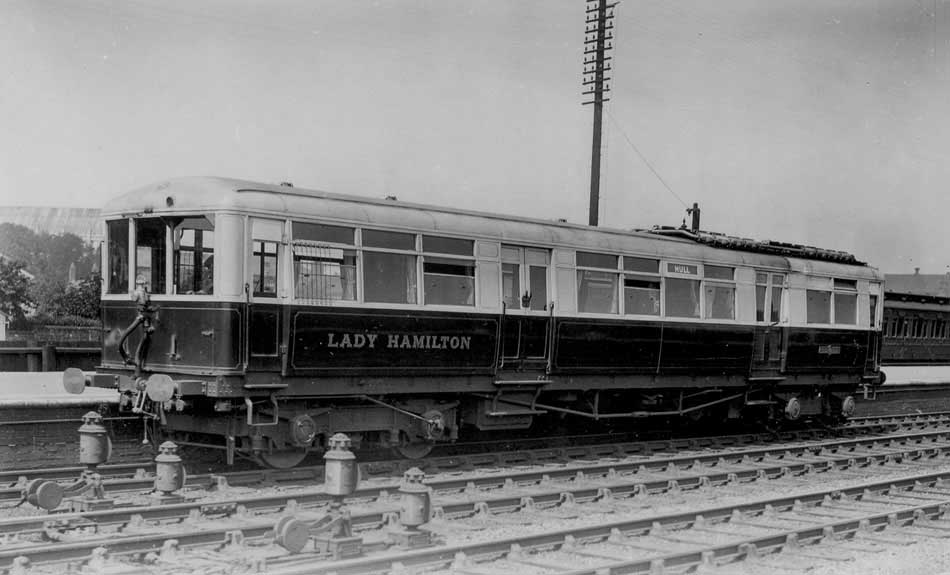

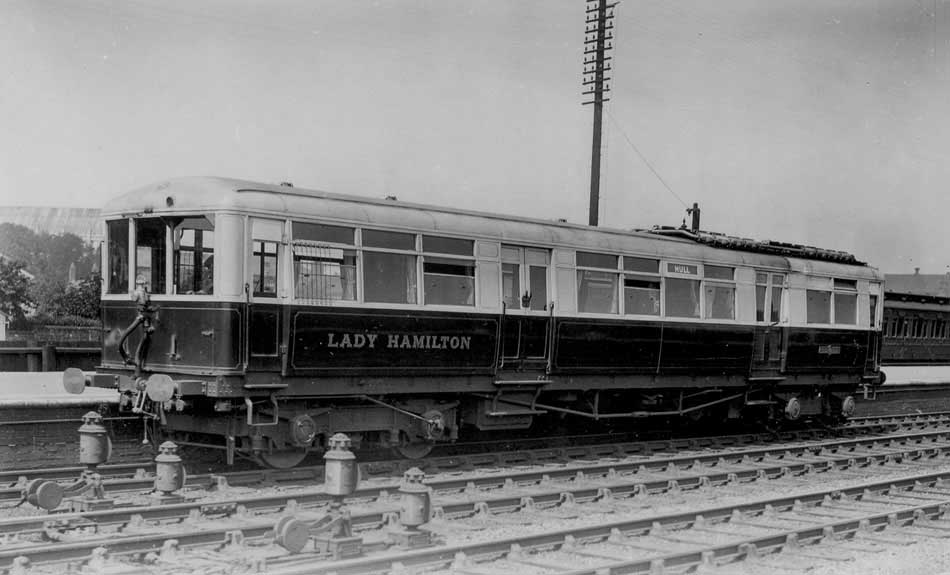

Lady Hamilton, #224

'Lady Hamilton' was tested on the LNER during January 1932, but was not purchased by them until April 1934 & taken into stock during June. This vehicle initially ran in grey livery, identified as 'Armstrong Whitworth Oil Electric Railcar', but by the early summer of 1932 had also received the dark blue and cream livery and now named 'Lady Hamilton'. Its livery was changed to green and cream in the summer of 1936.

Photograph courtesy LNER.

Platform 11 at York on January 20th 1932, an Armstrong Whitworth railcar in overall grey, later to become the 'Lady Hamilton'.

Early tests saw it run to Alnmouth and later on a publicity run past George Stephenson's birthplace near Wylam. On this trip the grey liveried railcar hauled an NER coach.

On January 20th 1932 the railcar now lettered 'Armstrong Whitworth Oil Electric Railcar' made a run to York, the next day working the York - Malton - Whitby - Scarborough - York circuit, the party onboard included some significant names associated with the LNER.

Another significant journey was made on July 7th 1932 when the now named 'Lady Hamilton' ran up to Kings Cross, remaining in the London area for several days to perform demonstration runs for railway officials and the Press between Kings Cross & Hertford. Its return to the north took place on July 15th 1932, taking just over five and a half hours, at an average speed of 47mph (maximum speed allowed was 65mph) with an average fuel consumption of 6.27 miles per gallon. Twelve stops and nine signal checks were included in the journey time.

Photograph courtesy LNER.

Its July 11th 1932 and the railcar mentioned in the above paragraph draws some attention at Hertford North. One wonders what it must have been like as a passenger in the seats nearest to the engine compartment when the railcar was being driven at their maximum speed of 65mph?

Photograph courtesy LNER.

A view from inside the railcar on its July 11th 1932 journey

A railway exhibition at Hull Paragon in the middle of October 1933 featured 'Lady Armstrong'.

Late in 1933 enquiries from the Southern Railway Locomotive Committee were sent to Armstrong Whitworth with regard to diesel railcars. These enquiries eventually led to one of the railcars visiting the Southern Railway for trials during 1934. It is not known if it was the 'Lady Hamilton' that made the visit since little is known of the trials apart from a note that at New Cross shed on April 28th 1934 the railcar sustained fire damage from steam locomotive sparks.

On April 26th 1934 the LNER purchased 'Lady Hamilton' & 'Northumbrian' for GBP5,500 each.

From June 18th 1934 the Lady Hamilton commenced working a service between Hull, York, Selby & Pontefract, running up a weekly summer mileage of 2,380, and 1,626 in winter.

'Lady Hamilton' probably only achieved two thirds of the mileage run up by 'Tyneside Venturer' - it seems to have been troubled by many issues that affected its reliability. It received unclassified repairs in January/February 1935 and general repairs in December 1935. Further unclassified repairs occurred in June, August & October 1936 and January & May 1937. These last repairs kept it in the Works until December 1938! Electrical problems saw possibly its last visit to Works during April 1939. After working in the Hull area it was taken out of service in early December 1939. This was the last of the three Armstrong Whitworth railcars to remain in service.

Northumbrian, #232

Like 'Lady Hamilton' this railcar started service in grey livery and nameless during February 1932. After its service on the LMS as the 'Armstrong-Shell Express' it would receive the dark blue and cream livery for its LNER service. Green and cream livery was applied early in 1936.

Photographer unknown

A view possibly of 'Northumbrian' on display at Newcastle with other rolling stock, date unknown.

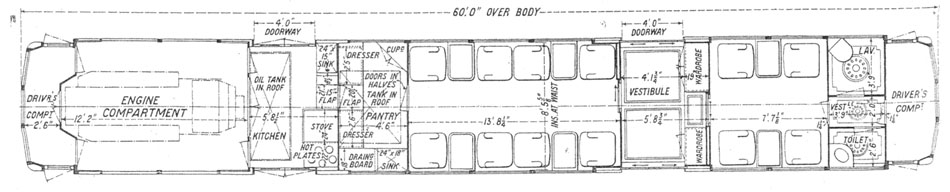

The third vehicle was named 'Northumbrian' and saw service on the LMSR & LNER. It had been completed in early 1932 and was tested between Newcastle and Hexham. On February 16th it trialled between London Euston & Castle Bromwich prior to its regular use in linking up the two sections of the British Industries Fair. For this special service the railcar was sumptuously equipped at Wolverton Carriage Works, the Pullman Car Company provided some of the fittings for the twelve people that could be accommodated. A complete kitchen was also fitted for serving meals enroute. The Fair operated between February 20th & March 3rd 1933, the railcar working one round trip each weekday. It left Euston at 11.35am and returned from Birmingham at 4.55pm, in each case the run was slotted in between two express passenger services, on the up Coventry - Willesden run it was required to maintain an average of 61mph. It had been renamed the 'Armstrong-Shell Express' for this event.

Over the 113 mile one-way route its maximum recorded speed was 70mph. Fuel consumption was 23 gallons, with the cost of fuel per gallon at 3.5d (old pence) fuel costs averaged 0.71d (old pence) per mile. In total on these workings 2,420 miles were travelled and 427 gallons of fuel consumed. This is believed to be the first diesel-electric express train service to be operated in the United Kingdom.

After this prestigous duty the railcar lost its lavish fittings and returned to more normal passenger duties with seating for sixty five passengers reinstated, eventually being purchased by the LNER in April 1934 and taken into LNER stock during June 1934.

'Northumbrian' was put to work in the Leeds area (Leeds - Harrogate - York) after being purchased by the LNER in June 1934. Late in October 1935 it was received at Darlington Works requiring major repairs to the power unit, which was removed and sent to Armstrong Whitworth's for repair. It was not until February 1936 that it returned to Neville Hill for further service. An engine failure was suffered during July 1936, the railcar remaining out of traffic for exactly a year, returning to further troubled service in the Hull area during July 1937. Two months were later spent out of service whilst a traction motor was repaired. 1938 seems to have been a good year, not being called for a general repair until May 1939. During this last spell of service it stood in very successfully for the troubled 'Lady Hamilton' on the Hull area services. Again repairs were not forthcoming and the railcar was taken out of service, having the least mileage of the three, perhaps 150,000 miles in total.

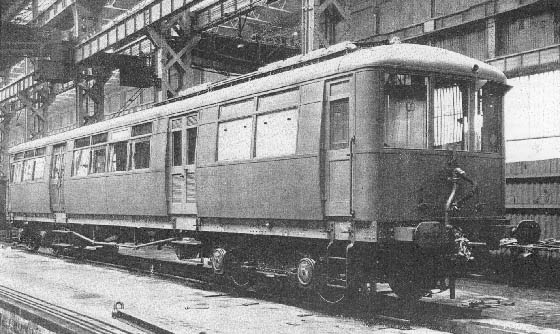

Photograph from an article in Railway Gazette.

A view inside the Armstrong Whitworth factory showing one of the three railcars that operated briefly on railways in the United Kingdom.

Photograph courtesy D M Newband.

LNER's No.25 Tyneside Venturer, date and location unknown. The railcar still carries its Armstrong Whitworth brand, but its now painted over.

Photograph courtesy LNER.

The railcar 'Lady Hamilton' in service, possibly in the Hull area.

Photograph courtesy Armstrong Whitworth.

A portion of the Armstrong Whitworth trade stand at the Shipping, Engineering & Machinery Exhibition held at Olympia during September 1933. Of interest in this view is, in the foreground an Armstrong-Saurer diesel engine complete with generator, control panel and traction motor for use in small shunters or railcars. Behind this sits a 250 hp Armstrong-Sulzer diesel engine used in the three heavier 'Tyneside Venturer' railcars.

Photograph courtesy Armstrong Whitworth.

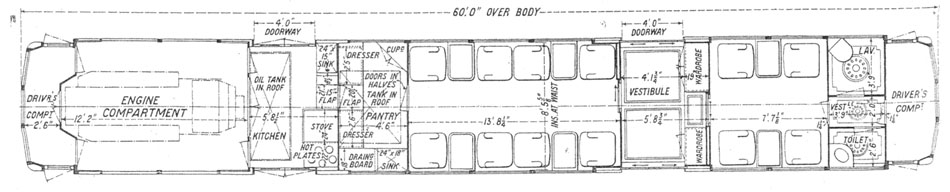

Internal plan of the railcar that was used on the Armstrong-Shell project, clearly showing the comfortable accomodation for just twelve passengers.

Photograph from materials provided by Alan Morley.

Side view of the Armstrong-Shell Express. The livery was blue & cream. The luxurious fittings included a well equipped kitchen, wardrobe and toilets - in normal service the railcars were not equipped with toilets.

The three railcars lingered for a while at Darlington Works, all being noted there during the summer of 1944.

These three pioneering railcars should not be mistaken with the very similar English Electric 1933 built diesel electric railcar 'Bluebird'. There is a remarkable resemblance in the body styles.

Photograph from materials provided by Alan Morley.

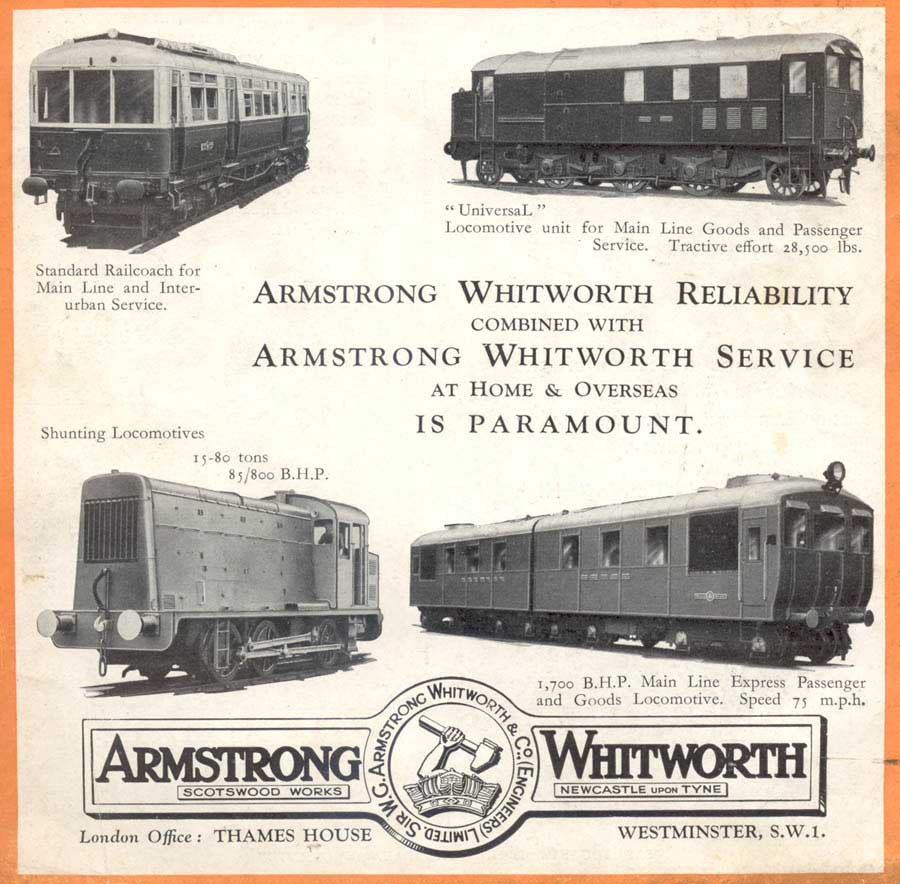

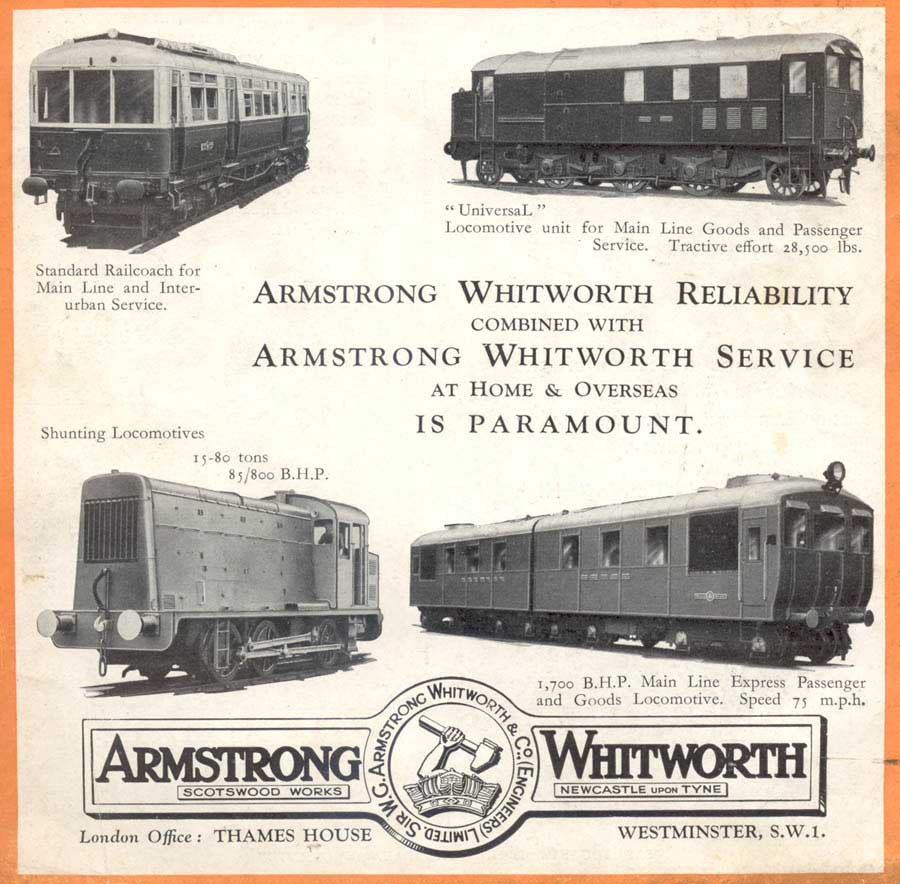

The cover of Diesel Railway Traction of December 29th 1933 included this advertisement for Armstrong Whitworth featuring three of their domestic products and one for the overseas market. All were powered by Armstrong Sulzer engines, with the shunting locomotive depicted being the basis for those later supplied to the LMSR.

A stylised view of Armstrong Whitworth's 0-6-0 diesel electric shunter operating at Heaton Goods Yard. This forty ton locomotive was offered with the 6LV22 or 6LD22 engine, some of these Armstrong Whitworth locomotives were the first to receive the LD series engines, forerunner of the LDA series that would eventually span the globe.

The locomotive carries no markings but is probably the prototype of AW's 0-6-0 shunters, which eventually was purchased for work in Preston Docks, remaining in existance until at least 1969. The locomotive is smartly lined out but there is no clue as to what the colour scheme is. Presumably the photograph is in the Newcastle area.

Builders plate No.D20 (7408, later 7058) sold at Great Central Railwayana Auctions for £620 during January 2014.

Sources:

Armstrong Whitworth Record, Autumn 1932

Armstrong Whitworth Record, December 1933

The Selection of a Diesel Shunting Locomotive, an Armstrong Whitworth Catalogue of December 1934.

Diesel Railway Traction (Railway Gazette supplement) February 24th 1933.

Diesel Railway Traction (Railway Gazette supplement) November 3rd 1933.

Diesel Railway Traction (Railway Gazette supplement) December 29th 1933.

Armstrong Whitworth - A pioneer in World Diesel Traction, Brian Webb (2010).

A Railway Harpist With Gresley Connection, Rodney Towers (Nov 2017).

The British Internal Combustion Locomotive 1894 - 1940, Brian Webb.

Page added March 28th 2004.

Page updated September 3rd 2024.

Return to Sulzer page

Return to site menu

|

|

|

![]()

![]()

![]()

![]()

![]()