The Shunters from the 1950s

Diesel Electric 0-6-0

Ten shunters had been ordered each year (1945/46/47) for construction at Derby. Although the demand for further shunters was high it would not be until 1950 that further orders took place - see table below. The first two orders were simply follow-ons to those placed in 1945, 1946 & 1947.

| Summary of the shunting locomotives ordered by British Railways 1948 - 1959 | ||||

| Order #, Date & Quantity | Cost | Delivery | Numbers | Retired |

| 4311; ??; 19 | ?? | 7/50 - 12/50 | 12069 - 12087 | 1968 - 1972 | 5127; ??; 15 | ?? | 6/51 - 6/52 | 12088 - 12102 | 1969 - 1971 | ??; ??; 15 | ?? | 1952 | 13000-13014, 3000-3014, 08001-08006 | 1972 - 1983 | 6232; 1953; 10 | ?? | ?? | 13015-13024, 3015-3024, 08008-08017 | 1973 - 1983 | 6739; 1953; 9 | ?? | ?? | 13025-13033, 3025-3033, 08018-08025 | 1972 - 1986 | 6839; 1953; 26 | ?? | ?? | 13034-13059, 3034-3059, 08026-08046 | 1972 - 1985 | 8240; 1954; 15 | ?? | ?? | 13082-13096, 3082-3096, 08067-08076 | 1972 - 1983 | 8340; 1954; 20 | ?? | ?? | 13097-13116, 3097 3116, 08077-08091 | 1972 - 1986 | 8350; 1955; 10 | ?? | ?? | 13117-13126, 3117-3126 | 1966 - 1967 | 9244; 1955; 25 | ?? | ?? | 13167-13191, 3167-3191, 08102-08124 | 1972 - ? | 9245; 1955; 25 | ?? | ?? | 13192-13216, 3192-3216, 08125-08148 | 1967 - ? | 9248; 1956; 53 | ?? | ?? | 13245-13297, 3245-3297, 08177-08227 | 1972 - ? | 252; 1957; 82 | ?? | ?? | 3337-3418, 08267-08348 | 1976 - ? | 658; 1958; 70 | ?? | ?? | 3503-3572, 08388-08457 | 1976 - ? | 1400; 1959; 40 | ?? | ?? | 3763-3802, 08596-08635 | 1977 - ? | 2277; 1959; 74 | ?? | ?? | 3937-4010, 08769-08842 | 1978 - ? |

Diesel electric 0-6-0 BR 12069 - 12102 (Order #'s 4311 & 5127)

This order was simply a follow on from the previous LMSR batch, the only change being that it was ordered under the auspices of post-Nationalisation British Railways. A following order for 12103 - 12138 was given to Darlington Workshops for construction.

The Derby built examples remained in service from December 1968 until June 1972. Nine went into industrial service, a number of those lasting long enough to reach preservation.

![]()

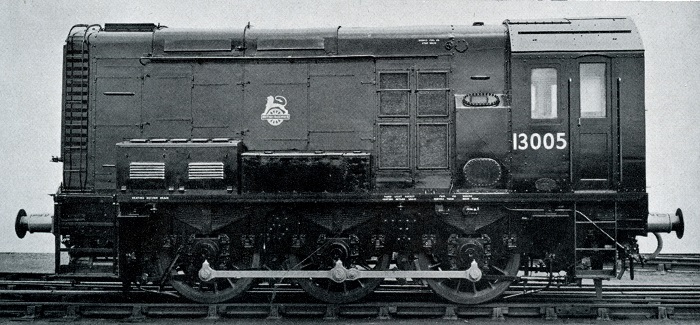

Diesel electric 0-6-0 BR 13000 series (Various Orders)

(Later number series D3000+, 3000+, 08001+)

The operational experience gained from the GWR/LMSR/LNER/SR shunters saw some changes made to the future orders. The most significant alteration to the existing design was the increase of the wheel diameter to 54 inches, which allowed the coupling rods and cranks rods to adequately clear the Southern Region's electrified third rail and yet remain within the universal 'L1' loading gauge. This change was based on the 26 0-6-0 locomotives built at Ashford in 1949 - 1952. These had been numbered 15211 - 15236 (Class 12). Other changes to future orders affected the chassis so as to accomodate equipment supplied from various sources with the minimum of alterations. Changes were also made to the cab.

Once the LMSR/BR orders for the Class 11 shunters were completed the ensuing orders reflected the changes referenced in the previous paragraph. These would eventually become known as the Class 08 totalling almost twelve hundred 0-6-0 shunters. Derby would build 508 of these locomotives, Darlington, Crewe, Horwich & Swindon also received orders.

The first of the standard Class 08s - 13000 to 13014 were completed at Derby during 1952, none went to the LMR, they were about equally divided between the WR, ScR & SR.

The first variation occurred with 13117 - 13126 (later 3117 - 3126). These ten machines were powered by a Crossley 6cyl ESNT engine with Crompton Parkinson providing the two traction motors. Whilst dual sourcing of equipment has advantages it soon became obvious that the non-English Electric equipped shunters were considered 'non-standard' and were the first to be withdrawn. These ten locomotives were retired between December 1966 and July 1967, all were broken up by May 1968. 3121 ended its days at Derby Works.

There followed two other variants, those powered with a Blackstone engine with GE (146 built) or BTH (15 built) electrical equipment, however these were not built at Derby. All the remaining Class 08's built at Derby were of the standard design. Although Derby's last shunter built was 4010, its order books originally contained a further order for D4011 - D4027, these were diverted to Horwich at the end of 1960. However the Works would remain heavily engaged in the building and repair of Classes 24/25/44/45/46 and the repair of much of the other LMR diesel fleet, and the commissioning of news diesels left the Workshops very busy!

![]()

1950

10001 was still at Derby Works during February 1950.

The prototype Fell locomotive, numbered 10100 was finally completed at Derby Works during the summer of 1950, with running trials commencing during December. This was a 2,000hp diesel mechanical locomotive, a unique locomotive to run on British Railways.

![]()

1951

During December 1951 10800 visited Derby Works and would be a frequent visitor here through April 1952.

![]()

1952

During July 1952 Fell locomotive 10100 returned to Derby Works for a lengthy stay after sustaining a major gearbox failure, remaining in Works at least until September 1953.

![]()

1953

![]()

1954

![]()

1955

As Derby and several other Workshops continued the building of the diesel shunters and BR Standard steam locomotives, a study into the building of diesel and electric locomotives and other forms of non-steam powered traction had commenced. This was revealed in the 1955 Modernisation Plan for British Railways.

During early February Derby Locomotive Works recieved four L.T.S.4-4-2s 41971/72/73/74 from Durranhill for scrapping. As L.M.S. 2153 - 2156 they had been transferred to Dundee in January 1948, then on to Perth & Stirling. They were highly disliked and were transferred to Skipton on June 19th 1948, but got no further than Durranhill where they all went into store, seeing no further revenue earning service. After nearly seven years in store (a record of some sort?) they were moved into the shed on February 6th 1955 to be prepared for travel. On February 10th they were noted in the Leeds area behind 90769, though a hot box on one locomotive saw them stopped at Holbeck. After arrival at Derby Works the locomotives did not linger, by early March they had been broken up. Forty years later some withdrawn Class 25s would have similar stories of a drawn out demise.

The Modernisation Plan, 1955 onwards (a brief summary)

The Sulzer powered Bo-Bo's & 1Co-Co1's

With the established history of diesel locomotive building at Derby Works it was no surprise that two of the Modernisation Plan designs were to be built there. Frames for twenty of the BR/Sulzer Type 2's & ten BR/Sulzer Type 4's were laid down in 1958/1959. The 'meltdown' of the intended direction of the 1955 Modernisation Plan led to many new orders being placed. The BR/Sulzer Type 2 had become one of the favoured 'standard' designs with the result that a further 131 were ordered, with Crewe & Darlington sharing in the orders. For the BR/Sulzer Type 4's a further 127 were ordered, shared between Derby & Crewe.

The first of the Class 24s, D5000 was completed during the summer of 1958, coming off the production line amidst new Class 08's D3545 - D3555. Based on my humble list D5000 was the 465th diesel locomotive to be built at Derby. A year later, in September, the first of the BR/Sulzer Type 4's was delivered, D1 'Scafell Pike' amidst shunters D3777 - D3783 and Type 2's D5020 - D5023. D1 was (give or take) the 527th diesel locomotive built at Derby.

As the 1950s closed Derby was busy, very busy, the last of the Class 44's, D10 'Tryfan' was about to be delivered, the shunters had reached D3802 and the Class 24's had reached D5068. The Works was also handling the repairs for the growing LMR diesel fleet and was commissioning the new diesels that were to be allocated to the LMR.

During 1960 the Class 08 & Class 24 production lines continued with the first of the Scottish Class 24's, D5114, turned out in April, featuring a redesigned cab roof incorporating a four charachter route indicater, and a cleaned up cabfront with the circular indicator discs removed. During spring a new production line opened up, being a follow on from the Class 44's, now with the uprated 2,500hp engine. The last half of 1960 was probably one of the busiest times at Derby with these three diesel types in production and ongoing repairs to both the diesel & steam fleet. As the year closed out Derby's final shunter, D4010 emerged alongside the last few examples of the Class 24's and the first half dozen Class 45's.

1961 started with the last Class 24, D5150, delivered in February leaving Derby to concentrate on construction of the Class 45's from the block D11 - D49. If my calculations are correct D21 became the 700th diesel built at Derby, outshopped in March. When the order for the Class 45's was completed another fifty six had been ordered (D138 - D193), substantially the same except for the electrical equipment, this last build became the Class 46's. The first of these was outshopped in November 1961.

Production of the Class 46's continued throughout 1962, with the last example, D193 being outshopped in January 1963, just in time to experience one of the severest winters in fifteen years. Coming after this production run was a further batch of Type 2's, now equipped with the uprated 1,250hp engine, the first of which had gone into D5151 - D5175, being built at Darlington. For Derby's examples the bodystyle remained similar to the final Class 24's, though with some noticeable changes, gone were some of the styling features and the boiler/fuel tank arrangement was altered. Derby's batch ran from D5186 - D5222, the order for D5223 - D5232 was transferred to Darlington whilst Derby worked on a cleaned up redesigned bodyshell for the next order of Class 25's. As usual with such a large order there were bound to be 'odd men out' and for Derby it was D7568 - D7577, these ten machines followed on from D5222 retaining the same body style but with GEC series Two equipment, yet numerically out of order.

D5201 was the 800th diesel locomotive built at Derby, delivered during June 1963.

At the end of the summer of 1963 the first of the frames were laid for the redesigned Class 25 bodyshell, by December 1963 D5233 was ready to go into traffic. Unique to this batch (D5233 - D5238) was the fitting of boilers, beyond D5239 all the Class 25's coming out of Derby were without train heating equipment.

Production continued on through 1963 & 1964 with the 900th diesel rolled out in November 1964, the lucky winner being D7502.

More of the same occurred in 1965, Derby's 950th diesel locomotive appearing as D7552 in July 1965. Oddball D5299 was delivered way out of sequence during November 1965. This had been the intended testbed for the R series Sulzer 6 cylinder engine, but major problems with the 12LDA28C in the Class 47's diverted all available resources away from new projects. Thus D5299 was completed as a normal Class 25 a year after its numerical sisters.

In September 1966 D7623 came off the production line, the 992nd diesel constructed at Derby. It would have been the last except for the request by Beyer Peacock Ltd, Manchester, who were building D7624 - 7677, to be released from their contract for the final eighteen locomotives. Derby took back the construction for D7660 - D7677 with the final locomotive delivered to traffic in May 1967, the last of 1,010 diesel locomotives built at Derby Works.

Although D7677 was the final diesel locomotive built at Derby, the Works completed one more 'locomotive' order, for six electric non-driving motor coaches to power the six Advanced Passenger Train formations. These were built in 1978/79 and were numbered 49001 - 49006.

10800 visited Derby Works during May to permit power unit repairs.

During the summer of 1955 10100 started a lengthy spell in Derby Works, remaining here at least until August 1957.

The delivery of increasing numbers of railcars to the network led to the overhaul work being handled by the regional workshops. Derby Carriage and Wagon Works allocated space totalling 40,000 sq ft in the lifting shop for the overhaul of railcars on progressive lines. However the overhaul of the railcar engines, gearboxes, transmissions and final drives would be handled by Derby Locomotive Works, with an existing shop being adapted for this purpose.

![]()

1956

The LMS Twins would spend quite a bit of time in Derby Works, having been absent whilst operating on the Southern Region, where Brighton Works took over their maintenance needs. When released in 1956 they would initially return to working over the Midland mainline.

![]()

1957

In June 1957 Derby turned out its last new steam locomotive, Standard Class 5 4-6-0 73154, the last of 2,941 to be built at Derby between 1851 & 1957. During August 1957 10000 made a visit to Derby Works.

![]()

The following paper 'The Design and Construction of the Two Derby Diesel Electric Locomotives' by G R Mahy was presented at the Midland Centre, Derby on March 17th 1959.

The paper discussed the Derby Type 2 and Type 4 locomotives, the sections relevant to the Type 2 locomotive is recorded below (some editing and paraphrasing has taken place).

Planning & Scheduling

With orders placed for twenty 1,160hp locomotives and ten 2,300hp locomotives and with the potential for more to follow, the previous experience with diesel locomotive contruction and repair acquired by Derby Locomotive Works whilst very useful was about to be taken to new heights. An erecting schedule was compiled, spreading evenly throughout the year the number of locomotives to be built. The erecting time, from 'frames down' to 'completion' was unknown, but the planning office utilising the information on hand assessed 12 weeks for the Type 2 and 16 weeks for the Type 4. It was recognised that these periods were short, especially for the first few locomotives.

With the erecting time known it was then possible to break it down into erecting stages and in conjuction with the schedule allow the creation of manufacturing schedules and material delivery dates. The drawing office covered all the major items of material and components required from contractors. Detail drawings were created, followed by the production office preparing specification sheets, operation layout sheets, route cards, material requisitions and wages tickets.

In general the planning and documentary work for the Type 2 & Type 4 was twice that of the Derby built BR Standard Class 5 Locomotive (see below); the first number represents the diesels, the number in parentheses is for the Class 5 steam locomotive:

Items included in specifications: 9,762 (4376)

Number of requisitions: 7,491 (4,119)

Number of items on material ordering sheets: 1,932 (842)

Number of operation layout sheets: 4,900 (3,000 approx)

Allocation of Work

The considerable differences between the construction of a steam locomotive and a diesel locomotive led to the Works adopting changes to areas where the new components required were not clearly defined when applied to the current allocation of steam work between workshops and craft grades.

Decisions taken included:

1/ allocating the underframe production to the boiler shop because the underframes were built up with channel sections and plate fabrications. The boiler shop would also handle the construction of the many jigs and fixtures needed, this would be a heavy workload leading to contractors handling the supply of battery boxes, water and fuel tanks. Once the jigs and fixtures tasks had been completed the boiler shop would be more focused on the future building programs.

2/ the sheet metalworking shop would handle the engine housing roof, radiator ducting, water ducting and numerous aluminium items. The staff requirement for this shop would be increased, with some work also allocated to contractors.

3/ the Brass Foundry would manufacture the nine cab, gangway and bulkhead doors as alumimium castings. This area would also handle other items as weight saving measures took place with future Type 2 orders.

4/ the electrical section was provided with an annex to facilitate the increased workload. At most stages of production there was some form of electrical work ongoing. The annex allowed for the production of power and control cables with connection sockets and terminals, where possible the conduits were pre-assembled. The locomotives contained about 2.5 miles of cable comprised of about 450 separate cables, each requiring terminals / fitting to accessories and continuity testing. Mobile battery charging equipment and mobile external starting equipment was produced here. The instrument section (repair & testing) also saw its workload greatly increase.

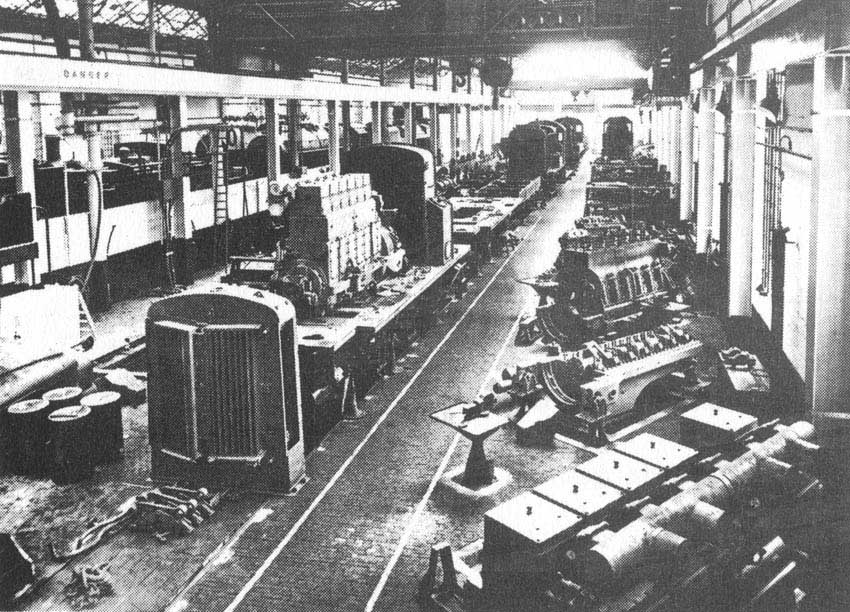

5/ in the erecting shop No.3 bay was partitioned for diesel production with the floor fitted with oil-resisting tiles. Customised engine stands were built (the existing cast-iron stands for steam locomotives were not suitable), since the power units were installed after the bodysides were completed there were clearance / height issues. The crane had clearance of 21 feet, in lifting a power unit the Type 2 the stands were 2ft 6in tall and for the Type 4 2ft 3in tall.

6/ the machine and fitting shop contained five hundered machines and employed eight hundred staff. This shop required careful management as it transitioned from steam to diesel production. Some jobs required considerable fine machining before welding of parts commenced, such as the bogie side frames, whilst other compoments required only rough machining, with fine machining carried out after fabrication, as with the axlebox guide blocks and brake hanger bosses. Correctly judging and controlling shrinkage and distortions during fabrication was a critical part of the processes in this area.

7/ the work of the paintshop frequently became a battleground between late erecting shop completion and expected date into traffic, so important to Headquarters. The diesel locomotives had the added burden of requiring much more internal painting than the steam locomotives and many surfaces required multiple coats of paint, each having to dry before the next coat was applied.

Staff Requirements

With Derby Locomotive Works having been in the business of diesel manufacture and repair since the 1940s there was already a core of workers familiar with this work. There was also an adaptability to move from steam to diesel work and the provision for training apprentices in diesel production.

With the extensive use of aluminium in the Class 24s, particularly the cabs, staff training was required in the technique of Argon arc welding.

Jigs, Fixtures and Pattern Equipment

With at least ten Type 2 & 4 locomotives forming the initial order a full set of templates, jigs and fixtures were needed, in itself a considerable amount of work. Once the drawings had been prepared, sets were sent to Crewe and Darlington for their production needs. Major items volumes were (1st number = Type 2, 2nd number = Type 4):

Templates: 1,931 & 2,241

Patterns: 151 & 85

Drill jigs: 127 & 107

Fixtures for welding, milling etc: 92 & 89

Fabrication of Body Side Truss

For the bodyside trusses the two main longitudinal angles and the extreme outer end angle presented no construction issues, but the top hat sections presented challenges. It was insisted that the center line of the top hats of both diagonal and vertical members must intersect as exactly detailed in the assembly drawings. The method chosen proved quite satisafactory, with shrinkage being within 1/32nd of an inch over a fabrication length of 36 feet.

The top hat sections after pressing were ground on the foot portion, this being the surface that made contact with the body side (skin) panels. Any imperfections would be greatly magnified when the skin plates were positioned and welded. The longitudinal angles, the extreme outer angles, top hats and gussets were then brought together in the welding fixture. Welding moved from the center outwards bringing together the top hats and appropriate gussets, once this was completed the welds to the longitudinals were made. This method reduced distortion to a minimum and allowed for the accurate placement of the members.

The rotary welding fixture used in the process was 40 feet in length. Truss statistics were:

Total length: 36 ft 6 in

Maximum height of truss only: 5 ft 6 in

Approximate weight: 19 cwt. 1 qtr. 8 lb

Approximate number of separate operations: 506 with 526 electrodes used

Construction of Underframe

The underfames were constructed using special jigs, with submerged arc welding employed as much as possible when welding the various members incorporated in the sub-assemblies. The use of sub-assemblies would reduce the final assembly time, but the assembly jig which allowed these components to be brought together would not allow complete welding because it was permanently in the horizontal position. To overcome this issue as much welding as possible was completed in the main assembly jig. Then the partially welded structure was removed from this jig and adjustable pivots were mounted at each end of the headstock. The assembly could then be rotated through 360 degrees to allow completion of the welding.

For some of the sub-assemblies it was necessary to fully machine pads, seating and locations at the sub-assembly stage, owing to their inaccessability in the final structure.

The completed underframe created the following details:

Finished size: length 46ft 10 1/2 in, width 8ft 9 7/8 in

Approximate weight: 5 tons 12 cwts

Number of sub-assemblies: 32

Number of details: 672

Approximate number of electrodes of various gauges: 3,943 with 2,470 separate operations.

With the underframe and side frame trusses complete, the underframe was removed from the jig and placed on floor stands, the side frames were lifted into position and welded to the underframe. The bulkheads, roof girders, C.S. bogie center etc were positioned and welded in sequence. The body unit is then handed over to the erection shop staff. The Type 2 had 138 brackets and snubs which were positioned and welded, these mostly provided floor supports. Water ducting and inter-cooling pipes were located within the main frame members, followed by the sealing plates. These were carefully positioned and welded to each other as well as the main frame, passing through these were snubs for the floor plates and required careful seal-welding. The sealing plates drained into two five gallon containers to capture any leakage / spillage from the engine area.

The empty body was then loaded with weights totalling about 14 tons, representing half of the total weight of equipment to be installed in the body. The body skin was then fitted and welded in position to each member of the side truss. The weights were then removed and cable ducting, water ducting, radiator ducting, radiators, electrical and brake cubicles fitted. Service pipes were fitted along one side of the locomotive whilst cables wrapped in brown impregnated canvas were laid in their ducting on the other side. These pipes and ducting were inbetween the sealing plates and the Kynal floor plates. At this time the battery boxes complete with sliding gear and the underslung fuel and water tanks were positioned.

The locomotive was then lifted off the stands and placed on 'three point stands'. The contractors had laid down a detailed plan for the fitting of the engine and this required the very accurate fitting of the four engine bearers. The special stands allowed for the precise drilling of the engine bearers and included the fitting of steel shims and rubber pads to ensure the engine was perfectly level. Each of the four bearers was monitored by an erector capable of making adjustments and all working in unison to meet the contractor's specifications. Crankshaft alignment was also monitored and all measurements recorded before the final bolting down of the engine.

Completed cabs from the coppersmith's shop were brought to the erecting shop, and after checking for proper fitting were bolted to the bulkheads and secured into the four supports under the floor. Elsewhere many components were added to the engine room, boiler room and cabs, work also proceeded on connecting all electrical circuits and services including the brake work controls from the cabs under the flooring. The steam generator was also wired and the water and steam connections made.

The bogies were then recieved from the bogie shop. Unlike steam locomotives, the bogies were wheeled at the bogie shop in order to save space in No.3 Bay. The locomotive body would then be lifted and positioned on its bogies and any connections completed. It would then be prepared for testing.

Test House, static testing and on-the-road testing

Prior to the construction of the Type 2s all testing had used water resistances. However with large locomotives orders expected a new test house had been completed utilising grid resistance of the expanded metal type, mounted in standard frames and housed on the first floor of the test house. The banks of resistances could be progressively connected across the main generator output providing current loading upto the maximum designated for the generator. Measurement of the outputs of the auxiliary generator and ancillary machines was also possible by the test house instrumentation.

A high voltage test was carried out (twice working voltage plus 1,000 volts with a minimum of 2,000 volts), power and control circuits were tested to earth and to each other. Equipment was then checked to ensure it operated in sequence. The traction motor leads were then disconnected and the generator connected to the test equipment. If all other functions were working correctly the generator was gradually brought up to full load, at which point the fuel rack and governer settings were adjusted as necessary to give the rated horsepower output of the engine. Tests were also made across a variety of speeds to compare the actual output with the declared characteristic curves. The locomotive was then disconnected from the test house equipment, traction motor cables reconnected and tests made to confirm all connections were correct and the traction motors rotated in the same direction.

Braking systems were tested and the steam generator fired up to confirm proper operation.

Testing on the road comprised a light engine run of fifty miles and a two hundred mile run with fifteen coaches. Frequently for the Type 2s the testing was carried out with pairs of locomotives. Painting of the locomotives could occur before or after the test runs.

![]()

1958

January 1958 saw Derby working through 0-6-0 shunter order D252 with D3409 - D3418 in various states of construction. Also present in the new diesel bay were the very beginnings of order D658 that would become D3503 - D3572. Derby's order book as of 1958 included shunters D3503 - D3527 for the Western Region, D3528 - D3572 for the Scottish Region and D5020 - D5029 for the Eastern Region.

Early February found nine diesel locomotives under repair, including 10800 and almost brand new D8010 & D8011, the latter pair having been recently on loan to Bradford.

March saw work commence on the first locomotive for order D251, D5000. The middle of March saw the Works including ED2, 15001, 11147 (to become 2508), 10000, 10001, 10201 & 10800. Noted in sorry shape were 12000 & 12001.

By April the shunter order had reached D3519 and four Class 24s were under construction. 10201 was still present in the Works.

By the middle of May Class 24 construction had reached to D5006, with D5000 almost complete. The shunter order was moving swiftly, all the Western Region bound shunters were in some state of construction whilst work on D3528 - D3524 for the Scottish Region had started. A considerable quantity of steam locomotives continued to pass through the Works, for classified and unclassified repairs, some for stripping and scrap, whilst others came for stripping prior to movement elsewhere for final scrapping.

Shunter construction had reached D3536 during June whilst Class 24 construction had stopped at D5006.

During July D8000 visited Derby for attention prior to commencing dynamometer car testing from Toton. Also present at this time was D8015 in the diesel shop. Shunter construction had reached D3539, Class 24 construction was still stalled at D5006, little would be done during the Works summer holiday. Towards the end of July D5000 was released from the Works and paid a visit to Marylebone for inspection by the BTC.

With the Works holiday over the construction picked up at Derby with shunters under construction reaching D3552 and work had commenced on D5007.

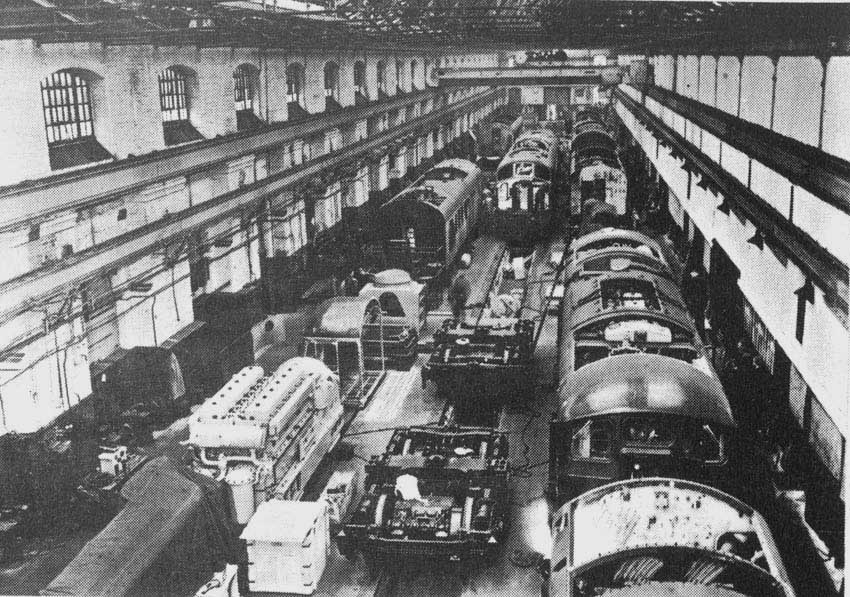

The Works Open Day on August 30th featured on display in front of the Works offices: D3542, D5001, D5700, 70017 & 92166. The 9F was equipped with a mechanical stoker was was on its way to the Rugby Testing Station. Visitors to the Works could find three production lines (see photos above) of new diesels involving Class 08 shunters, the D5000 series Type 2s and the very beginning of the larger Type 4s to be numbered D1-D10. Also present were many steam locomotives undergoing repair.

Shunter construction had reached D3558 during September, Class 24's were up to D5009 and the frames of D1 & D2 were noted. Steam repairs continued at a high volume to LMSR and BR Standard types, some received repaints on outshopping others did not.

By October construction had commenced on D3562, D5010 & D3, priority appears to have been given to the shunters and then the Class 24's. A recent visitor to the Works was 15000 which was outshopped in green livery.

Fell locomotive 10100 returned to Derby Works for the last time during November 1958. A train heating boiler had caught fire at Manchester Central on October 16th 1958 causing serious damage to other parts of the locomotive, sadly ironic that the locomotive would be retired by a component in no way related to its very unusual engine/gearbox set up. And also ironic that the heating boiler would become the achilles heel for many of BR's modernisation fleet locomotives. The Fell locomotive was withdrawn after reaching Derby, with no future it would be slowly stripped of parts.

Elsewhere in the Works shunter construction had reached the last of the present order, D3572 whilst no new construction had occurred on the Class 24/44's.

Little change was noted in December on locomotive construction with the shunters moving along the fastest.

Details from a Derby Locomotive Works publication prepared for the visit of the Chairman & Members of the London Midland Area Board on Thursday November 5th 1959 2.45pm to 4.15pm. Cars from the Mifdland Hotel were to go direct to the Boiler Shop Entrance (Bottom Yard).

Introduction.

The main activity of the Locomotive Works, Derby, is to build a proportion of the new locomotives required by the British Transport Commission, and to maintain in good repair a large number of the locomotives in service, both steam & diesel. Comprehensive facilities are also provided for the repair and testing of all types of diesel engines used as the propulsion units for two-car and multiple railcar units. In addition a considerable amount of work of great variety is performed on behalf of the Outdoor Machinery and other Departments, since the latter do not possess facilities for the execution of heavy work of which the Works is capable.

General Information.

Total area of Works: 47 acres

Area occupied by Shops: 13 acres

Total number of Wages Staff employed: 3,526

Average weekly wages bill: GBP38,600

Number of Salaried Staff in Shops & Offices: 303

Output of Repaired Locomotives during 1958:

General repairs:

Steam: 277

Diesel: 7

Heavy Intermediate Repairs:

Steam: 107

Diesel: 11

Light Intermediate Repairs:

Steam: 154

Diesel: 0

Heavy Other Repairs:

Steam: 4

Diesel: 6

Heavy Other Repairs:

Steam: 85

Diesel: 20

Totals:

Steam: 627

Diesel: 44

Output of New Locomotives 1958

Diesel Electric Shunters: 81

1,100hp Bo-Bo Type 2 D.E.: 7

Number of Diesel Railcar engine units reconditioned during 1958: 220

Scheduled output of New Locomotives 1959

Diesel Electric Shunters: 40

2.300hp 1-Co-Co-1 Type 4 D.E.: 10

1,100hp Bo-Bo Type 2 D.E.: 35

Planning and initial manufacture of items for Main Line Diesel Locomotives for 1960

Works Organisation & Administration

The Works is controlled by a Works Manager, an Assistant Works Manager and a number of Assistants eg. Production Engineer, Assistant for Locomotive Repairs, Plant Engineer.

The Production Office comprises the following sections:

Estimating, Ordering, Progress, Ratefixing and Jig and Tool, each Section being controlled by an Assistant responsible to the Production Engineer.

The Organisation controls the manufacture of all types of work., whether it be for new locomotives, stock replenishment or work of a miscellaneous nature. Operation layouts are compiled by the Estimating Section for all details and these indicate the machines to be used, feeds, speeds etc. Estimates for new work and modifications to locomotives are also prepared and the actual expenditure is controlled by the Section. Special tools and fixtures are designed by the Jig and Tool Section, whilst the progress of material delivery and manufacture is pursued by the Progress Section, who also prepare the prospective dates on which material should be to hand so that all machine and fitting groups can be loaded with their proportion of work. Extensive use of 'Kardex' slotted charts enables the Progress Staff to tell immediately when and where delay is imminent so that pressure can be exerted where necessary.

Time Studies are directed from the Ratefixing Section by Staff designated as Ratefixers, who observe and register piecework prices. Concise records are kept by this Section of all operating times and prices. Production within the Works is assisted by well established Incentive Schemes, and their value has been proved over a number of years.

The Locomotive Repair Organisation controls the shopping of locomotives for repairs, the provision of an economic stock of boilers, the repair methods and the authorisation by Initial Examiners of all repair work to be carried out on locomotives, tenders and boilers. Responsibilities embrace the progressing of material for locomotives on the Works and also for those awaiting components at Motive Power Depots. Forecasts are made for the future requirements of major components such as cylinders, tyres, crank axles, wheels etc which ensures their availability when the locomotives are received on the Works for repair. The progressing of special fitments and modifications to locomotives is also undertaken.

The Plant Engineer is responsible for the purchase, installation and modification of all Works Plant and Machinery. Life expired and obsolete machines are earmarked for replacement and competitive quotations are obtained for equipment of modern design before orders are finally placed. Layouts of the new schemes and the design of specialised machinery are carried out in this Office which also controls and follows up their installation. Close co-operation between this section and the Millwright's Shop ensures that a strict schedule is maintained for the repair and overhaul of machinery and plant on the Works.

The Works Inspection Department ensures that components are machined within drawing tolerances which guarantees interchangeability and easy assembly. The Department is responsible to the Works Manager through the Chief Finished Work Inspector.

Works Surgery

All the first aid appliances with which the Works Surgery is equipped are of modern design, and a qualified Doctor together with Nursing Sisters are in attendance. In addition to the attention given to personnel involved in accidents, minor ailments are also treated. It is not intended that the Works Surgery should surplant the General Practitioner but that it should assist Staff with minor illnesses to remain at work. A supplementary service to the Surgery is the First Aid practised by Works personnel trained at the Railway Ambulance Classes who use the kits which are widely distributed throughout the Workshops. Adjoining the Surgery is a garage which houses the Works Ambulance.

Canteen Facilities

The Works Canteen is a building modernised at a cost of GBP20,000, which was officially opened in March 1943. It covers an area of 15,400 square feet and is one of the finest Works Canteens in the Midlands. 960 persons can be accommodated in the Main Hall, the meals being supplied fram an up-to-date kitchen. At one end of the Main Hall is a stage complete with property and dressing roms. The Canteen is directed by a Committee under the Chairmanship of the Works Manager, and a Manageress is responsible for the day to day business of the Canteen. A Mobile Canteen is in operation which supplies tea, biscuits, cakes and other refreshments to the individual Workshops at a fixed time during the morning.

The Works Training School

The Works Training School is situated in the centre of the Works thus ensuring the closest contact between the School and the Works, as well as maintaining the atmosphere of the Workshops. The School is self-contained and covers an area of 13,000 square feet. It includes a lecture room and a science room. Accommodation is available for a hundred trainees and the approximate intake is thirty boys every four months. Provision is made for Workshop training in the following trades: Joinery and Patternmaking, Moulding and Casting, Plate and Sheet Metalwork, Smithing and Forging, Turning and Machining, Fitting and Assembly and Electrical Work. The School hours are 8.15 am to 12.25pm and 1.25pm to 5.00pm Mondays to Fridays. Two-thirds of the total available time is devoted to practical work and the remainder to classroom instruction.

Apprentice trainees are paid the standard scale rates for Juniors, a monthly bonus being awarded as an encouragement for good work. The Chief Instructor is directly responsible to the Assistant to the Works Manager (Training). Practical instruction in the Workshops is covered by Instructors who have been selected for their knowledge of the trades concerned. Theoretical instruction is given by lecturers from the Staff of the Derby and District College of Technology and selected members of the Railway Technical Staff.

Apprentice Training

1. Trade Apprentices

After their initial twelve months course in the Works Training School, the boys enter the Workshops as Trade Apprentices and are systematically moved from Section to Section under the Progressive System of Workshop Training, the work undertaken being in ascending order of training importance. The ability and attention to duty of each Apprentice is recorded, and on the completion of an Apprenticeship, a report is submitted by the Works Manager to the Regional Headquarters. From the study of these detailed reports it is possible to select young men who, by their progress, ability and educational successes have proved themselves worthy of promotion.

2. Engineering Apprentices

Promotion to the status of Engineering Apprentice is made from Trade Apprentices who have made outstanding progress in both their practical work and technical studies and from boys leaving Grammar School who have obtained their General Certificate of Education in the necessary subjects. Engineering Apprentices spend a short time in the Training School before being transferred into the Works where they receive a general training in engineering by passing through all the principal departments. They are required to attend approved courses of day and evening study at a Technical College or Institute and fit themselves for eventual application for membership of either the Institution of Mechanical Engineers or the Institution of Electrical Engineers.

3. Sandwich Course

This course lasts for five years and consists of alternately spending five months at the Derby and District College of Technology and seven months in the Department of Railway Service to which the Student is allocated. Candidates may be selected from either the Engineering or Trade Apprentice categories if their progress suggests that they will benefit from the course.

Wheel Shop

Wheels, tyres and axles are manufactured, assembled or repaired in the four separate bays of the Shop. In the South-Eastern bay there is special machinery for the high speed boring of wheel tyres and for turning wheel centres, also gas furnaces for shrinking tyres on to wheel centres. The cleaning of wheels before repair is carried out in a wheel washing machine. The wheels are totally enclosed and are revolved whilst a hot caustic solution under pressure is sprayed upon them. This task, previously undertaken by manual labour, is completed in six minutes. Heavy centre lathes are installed in the next bay for rough turning and finishing axle journals, cranks and wheel seats. In the third bay is hydraulic pressure equipment for pressing wheels on and off axles, and a special machine for grinding external crankpins in situ. In the Northern bay, there is heavy machinery for the turning of tyres which is also used for facing smokebox joint rings to ensure an airtight joint. The Shop contains the heaviest turning machinery in the Works; special techniques and improved tools playing a large part in the rapid production of high quality wheel sets.

Boiler Shop

The two main classes of work are firstly the repair of locomotive boilers and secondly the cutting and fabrication of components from plate and rolled sections. Tank repairs are carried out in one bay of the Shop, the tanks being so positioned that all repairs can be completed without their being removed. Each tank is tested after repair before it is returned to service.

Boiler repairs are carried out on the South-Eastern side of the shop. The layout allows the boilers to be repaired on a progressive system, distinct operations being performed in specific positions which are equipped to deal with the particular work in hand. In this way the required output is obtained with the minimum number of boilers in the Shop at any one time. The special equipment consists of rigs for removing the firebox stays in the initial stages and for later reaming and tapping holes for new stays. Many of the heavier tools are suspended by balancing devices from an overhead framework. Standard equipment includes a hydraulic riveting plant, electric rivet heaters, electric stay drilling and tapping machines and pneumatic riveting tools and stay drivers.

One Section deals with the cutting and machining of plates and the building-up of complete assemblies, some of the more notable items being the side truss structures for the main line diesel locomotives, which are assembled in two large rotatable welding jigs; the Type 4 locomotive cabs; roof sections; frame stretchers and many other components for both main line and shunting locomotives. Another bay houses the heavy drilling, planing and shaping machines, whilst nearby there are small hydraulic presses which produce many thousands of firebox baffle plates and other small pressings.

One of the bays contains separate cubicles for Electric Arc Welding. Fabrication of many locomotive details by electric welding has increased greatly in recent years and as a result, the elimination of much riveting, bolting and other laborious work has been made possible. Considerable quantities of locomotive details that would otherwise be put to scrap are reclaimed by building-up with electric weld deposit on cracked or worn surfaces. A Metropolitan Vickers machine for the automatic deposition of electric weld on shafts, axles and beam ends is available; also plant for building up non-ferrous details by metal spraying. Welding techniques are constantly being improved and in addition to the Nitrogen Arc welding of copper firebox plates two comparatively new processes, those of Submerged Arc welding for selected steel details and the Argon Arc welding of aluminium, have been introduced.

Heavy duty presses of 500 and 350 tons capacity, operated by hydraulic pressure at 1,650lbs. per sq. inc, deal with the pressing of major locomotive and boiler components from copper and steel plate. Before pressing the plates are heated in oil-fired furnaces to approximately 1,000C. Situated on the South-Western side of the Shop are the large power operated plate rolls which are used for straightening plates or rolling the curved barrel plates for boilers.

Coppersmiths Shop

All types of copper and fabricated steel pipework together with sheet metal work such as dome covers and locomotive boiler clothing details are produced in this Shop. Hydraulic presses are used for pipe bending and an electric spot welding machine is used extensively. The fabricated cabs for the Type 2 main line diesel locomotives consisting of a framework of special aluminium section covered with aluminium sheet are made in this Department.

Erecting Shop

Locomotive and tender repairs are carried out on a progressive system in which separate gangs of men deal with each class of work. The time allowed for the repair of a locomotive ranges from 5.5 days to 9.5 days according to the nature of the work. The Shop consists of three bays, two of which are used for steam locomotive repair work. The total accommodation of these two bays is a maximum of twenty five locomotives and ten tenders, and each bay is equipped with three overhead electric cranes of 50 tons capacity. The third bay has been partitioned from the other two and modernised to establish the conditions necessary for the construction of main line diesel electric locomotives. After laying down the underframes at the Northern end, the locomotives pass through the progressive stages of erection as they proceed to the South-Eastern end of the bay, by which time they have reached an advanced stage of assembly. This bay is equipped with four overhead electric cranes, two of 50 tons capacity and two smaller auxiliaries.

Two types of main line locomotives are being built; the Type 4 2,300HP with a 1-Co-Co-1 wheel arrangement and the Type 2, 1,160HP with Bo-Bo wheel arrangement. Both types are powered by Sulzer diesel enginesbut the former has Crompton Parkinson transmission whilst the latter has BTH equipment.

Diesel Finishing Shop

The diesel locomotives are transferred from the Erecting Shop to this Department for the final assembly of the remaining components. Some air line and vacuum tests are also carried out whilst the locomotives are in this building. The Shop is equipped with a 30 ton capacity electric overhead crane.

Diesel Locomotive Test House

After completion of the diesel locomotives in the Finishing Shop they are supplied with fuel and water and passed to the Test House. This building was brought into operation in 1958 and employs naturally ventilated grid resistances of the expanded metal type which can be progressively connected across the main generator output so as to give increasing steps of current loading from zero to the maximum for the generator of the locomotive being tested. Measurements can also be taken of the outputs of the auxiliary equipment which absorb some of the output of the main generator. There is an intercommunication system between the Engineer on the locomotive and the Inspector in the test room in order that close control of the test can be maintained. This test procedure ensures that newly constructed locomotives are giving their full rated output at each point of the control and enables load tests to be carried out on locomotives coming into the Works for attention to the power unit before repairs are effected.

Machine and Fitting Shop

Covering an area of 108,000 square feet, this large Shop contains almost 500 machines and has a staff of approximately 800 men. Production is of a batch type and to give the best conditions for work of this nature, the machines are concentrated into groups according to their type e.g. drilling machines, lathes, planing machines. This feature also applies to the fitting groups, where men are grouped in sections to deal with the fitting operations performed upon the various components. One Section deals with locomotive and tender frames which are burnt-out to profile on a large oxy-acetylene cutting machine and are straightened, drilled and machined with the minimum of handling.

At the South-Eastern end of the shop are the separate Sections concerned with the machining and fitting operations on axleboxes; brakework; the Section which deals with the machining of brass details for the many valves, cocks, injectors and ejectors which are fitted to locomotives; and a further Section concerned with the turning, screwing and tapping of many small components such as bolts, nuts, pins, studs and rivets. This latter Section is staffed entirely by Apprentices. Close by, is the battery of Automatics which is employed upon similar work where the production is required in quantity.

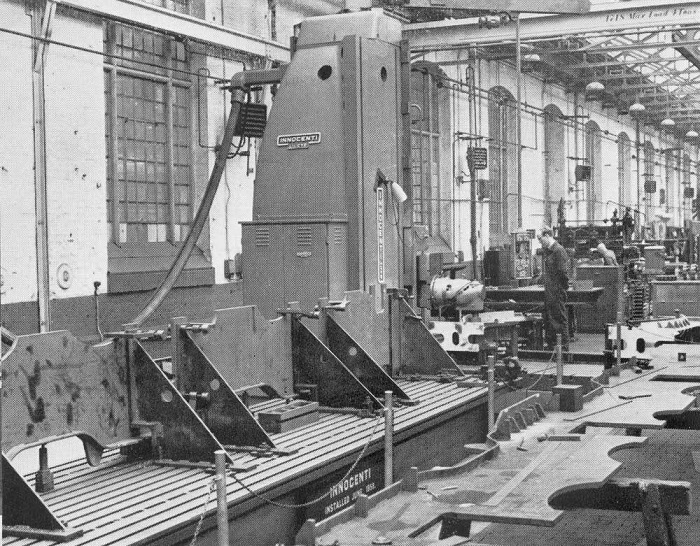

Situated in the centre of the Shop is the Toolroom, which is equipped with special gear-cutting, thread-grinding and jig-boring equipment, producing tools and gauges to the necessary close limits. These tools and gauges are housed in a well arranged Gauge Stores which is attached to the Toolroom. On one side of the Toolroom, is the General Turning Section which is an extensive layout of every type of lathe, both vertical and horizontal, and a Grinding Section equipped with many different types of machines; whilst on the other side of the Toolroom the Shaping and Slotting Sections are located. Near to the last named Sections is the large Innocenti boring and milling machine which has been recely installed. At the North-Western end of the Shop, are the Drilling, Planing and Milling Sections and on the large machines of the latter Section the familiar coupling and connecting rods are machined.

Heat Treatment Plant

The Heat Treatment Plant is located in a separate building, adjacent to the North-Western end of the Machine Shop. The Plant consists of three salt baths, including a cyanide bath, for the heat treatment of all types of carbon and alloy steel tools and components, under carefully controlled and electrically recorded conditions. The Works Metallurgist is actively concerned in all matters relating to the heat treatment of various materials.

Brass Fitting Section

A building which was added to the Works in 1957 houses the Brass Fitting Section, and it provides increased accommodation combined with a more efficient layout than that used when the Section occupied part of the main Machine Shop. The Section deals with the repair and assembly of all brass fittings such as injectors, ejectors and the many valves and cocks, which are tested before being fitted to locomotives.

Diesel Erecting Shop

This Shop was adapted in 1947 for the repair and construction of diesel main line and shunting locomotives, although the construction of main line diesel locomotives now takes place in the Erecting and Finishing Shop. The Shop is equipped with two 50 ton capacity overhead cranes, the crane runways having been extended to the full length of the Shop in 1955 in readiness for the increased use of diesel traction due to the modernisation of British Railways. The first two 1,600HP diesel electric passenger locomotives to operate in this country were built in this Shop.

Paint Shop

Complete painting of locomotives is normally carried out at the time of a General Repair and takes three to four days. In the interests of economy only patches and renewed details are painted at an Intermediate Repair. Locomotives receive the minimum number of coats necessary to prevent normal corrosion and the resultant wastage and, in the main, synthetic paints are used as these provide better finish and durability.

Diesel locomotives require a great deal more internal painting than steam locomotives and all service pipes and connections have to be painted in their appropriate B.S.S. colour. Staff of this Department are also engaged upon the internal painting of the Workshops and the painting of Works Equipment.

Diesel Railcar Engine Repair Shop

This building was adapted in 1955 to give the best layout for flow production methods. Engine units are received at the South-Western end of the Shop where they are cleaned in three stages. The first stage is a general exterior cleaning, followed by a second stage after the units have been stripped into sub-assemblies. Both of these cleaning operations are performed by passing the components through a twin-chamber spray booth. The sub-assemblies are then stripped into their respective details and are immersed in baths for the final cleaning operation.

The cleaned parts are examined and those details which are retained are placed in storage racks to await repair. Parts which require machining are passed to the Machine Shop, whilst other items are dealt with at the fitting benches in the Shop. New and repaired details are stored in racks adjacent to the engine assembly positions.After assembly the engines are inspected before being transported to the dynamometer test plant which is housed in a separate building near the Shop.

Pattern and Joinery Shop

This Shop consists of woodworking benches on either side of a central gangway which divides the Patternmaking and Joinery Sections; together with a Machine Section for their joint use. The Joinery Section deals with all the woodworking requirements of the Works including alterations, maintenance work and special fitments.

The Patternmaking Section is concerned with making and modifying patterns for both hand and machine moulding in the Brass Foundry. In connection with the production of multiple patterns for machine moulding plates, metal patterns have recently been replaced by patterns produced in a plastic process using an epoxide resin. This modern process is proving to be most satisfactory and has many advantages over the previous method. All the woodworking machinery is of modern design, and includes a Wadkin Universal Milling Machine which is capable of machining many difficult contours on patterns.

Millwrights Shop

The function of this Shop is to maintain all Works services and buildings (excluding the electricity supply and telephone system) for which purpose the equipment installed covers all types of work. A large proportion of the Staff are engaged in other Shops on the installation and maintenance of machine tools; gas, water, compressed air, and heating apparatus. A considerable amount of production work for the diesel building programme including the air, vacuum and water piping is also undertaken. Hydraulic lifts on Derby Passenger Station and others in the Works are served by feed pumps, and it is another duty of the Millwrights Shop Staff to maintain these units. Miscellaneous work includes cycle repairs and leather work.

Attached to the Shop is a separate Section which deals with the overhaul of Steam, Diesel and Manual travelling cranes of up to 50 tons capacity, which are used for general and breakdown work. A test bed is provided which enables exhaustive crane tests to be carried out on the completion of repairs.

Smith and Spring Shop

The North-Western end of the Shop is laid out for the production and repair of laminated springs. The factor which determines the extent of a repair is the Scrag Test, to a deflection greater than that experienced under service conditions - in many cases this avoids the necessity of re-hardening and tempering. Defective plates are replaced, the spring plates being heated in oil-fired furnaces and, depending upon the material, are oil or water quenched. Springs are machine-buckled by hydraulic equipment and are tested before leaving the Shop to ensure that the correct deflection in relation to the load is obtained.

The Centre of the Shop consists of the Blacksmiths Section where the general forgings required by the Works are manufactured by hand or by means of the battery of 10 cwt. Massey Electro-pneumatic hammers. Two Flash Butt welding machines, one capable of welding an area of 9 square inches and the other 5 square inches, are located in this part of the Shop. At the South-Eastern end of the Shop is installed the equipment for the quantity production of nut, bolt and small detail forgings.

Boiler Mounting Shop

Repaired boilers are received from the Boiler Shop for the fitting of internal tubes and pipes, regulator valves, superheater headers and steam valves. Wherever possible the boilers are arranged so that the men may work at ground level without the use of staging. Hand filing for the purpose of bedding components and making joints is reduced to a minimum by the use of portable grinding tools. When completed, the boilers are transferred to the test plant, where they are subjected firstly to an hydraulic test for 5 minutes at 50% above the normal working pressure, and secondly to a steam test for one hour at 10 lbs. per square inch above the normal working pressure.

Sheet Metalwork Shop

The Sheet Metalwork Shop deals with the manufacture of all types of high-grade tinware and general sheet metalwork for Works maintenance requirements. Major components for the Type 2 diesel main line locomotives which are produced by the Department include sections of the locomotive roof, and radiator and water ducting, all of which are manufactured from aluminium sections and sheet. One of the machines in this Shop is a Power Press of 100 tons capacity which is used for blanking and drawing operations on components which are required in quantity.

Hot Brass Pressing Shop

For suitable locomotive and carriage components the hot brass pressing process is superior to the production of details by casting, since they are produced to such close limits that machining is either greatly reduced or entirely eliminated. Billets are sawn from brass bar and are then heated in gas-fired furnaces prior to being inserted in the dies of the four heavy presses.

Brass Foundry

Recent re-organisation has resulted in the Brass Foundry now being located in the former Iron Foundry building. Non-ferrous castings are produced for the Derby, Crewe and Horwich Locomotive Works and the Derby Carriage and Wagon Works. The more intricate details are produced by hand moulding but for the quantity production of other items, extensive use is made of machine moulding methods. The Foundry is equipped with eight furnaces of which five are Morgan oil-fired crucible furnaces, each having a capacity of 600 lbs., linked with the moulding machines by roller conveyors. The Fettling Section is well equipped with shot blast machines, saws and grinding machines.

Works Internal Transport

There is a considerable amount of internal rail transport, effected by means of locomotives provided by the Operating Department, a large number of wagons being received and despatched each day. It is the duty of the Internal Transport Section to see that the wagons are moved to the correct location and that the number of wagons on the Works is kept to a minimum. Road transport between Works Departments is by a tractor and trailer system which is organised to efficiently transport material and minimise the light-running of tractors.

A number of other vehicles including mobile cranes, the lorry and a loading shovel are used by the Department. Five of the tractors, the lorry, and a mobile crane are fitted with radio telephone transmitter/receivers, the control station being located in the transport foreman's office. Repairs to the motor vehicles up to, but not including, rebores are carried out by the Maintenance Staff at the Works Garage.

Mechanical Handling

Mechanical Handling has been introduced in the Works by a system of palletisation for the larger components and toteboxes for smaller details, and this system is most apparent in the Machine Shop. Movement of pallets is by means of Fork Lift Trucks (of which the Machine Shop has two, the Erecting Shop one, and the Smith's Shop one), battery electric stillage trucks, and hand operated pallet trucks. A yard model, heavy duty Fork Lift Truck, is a further item of equipment used by the Internal Transport Department.

The Power Station

Situated on the North-Eastern bank of the Derby Canal, the Power Station is being re-organised under the Modernisation Plan. Formerly its prime function was the production of electrical power, but in the future the main power requirements will be taken from the East Midlands Electricity Board. When the Station has been re-built it will be equipped with five boilers, three of which are new, and two new turbo-alternators of the back pressure type. Production of steam for the Works processes and heating will be the primary function, but some electricity will be produced, at a very low cost, to supplement requirements.

Compressor House

The Compressed Air Plant comprises a battery of three Ingersol Rand water-cooled compressors which are each rated at 800 cubic feet of air per minute. These compressors supply compressed air to the whole Works at a pressure of 100 lbs. per square inch, and are each driven by a 150HP synchronous induction motor. The motors have a leading power factor which is so arranged to assist in correcting the power factor for the whole Works electrical supply.

Locomotive and General Stores

The Locomotive and General Stores Department is a separate Oganisation which, under the direction of the Area Storekeeper, works in close liason with the Works Department. The Locomotive Stores houses all locomotive details, chiefly in one large building, whilst the General Stores supplies general user materials.

Works Stores

A separate building adjacent to the Erecting Shop, and under the control of the Works Manager, is used for the storage of finished details required for the current new engine building programme.

![]()

1959

The 1959 building programme called for Derby to handle D5066 - D5075 for the Eastern Region & D3763 - D3802 for the London Midland Region.

The New Year brought new construction to the Works with work taking place on D5011 - D5013 and D4, whilst a new order of shunters (order D1400) started with D3763 & D3764. Under repair in the Works included 10000, 10800, 12000, 15004, D8014, ED2 & ED7. Also accumulating in the Works were a growing number of stored steam locomotives, others could also be found around the station area and at St Mary's goods yard.

Even though D1 was still months away from completion an order was confirmed for 137 further locomotives of the Type similar to D1-D10, currently under construction at Derby. This new order would be split between Derby & Crewe.

During February the shunter construction had advanced to D3765 and the Class 24's had reached to D5016. It was at that this time the D1 - D10 locomotives would receive names of mountains within England & Wales. Visitors to the Works included 10001, 10203, 10800, 12000, D8001 & D2910. The withdrawn Fell locomotive had now migrated from the depot to the Works.

By March the shunter construction had reached D3767 and D5017 had been started. Diesels under repair included 10202, 10800, 11127 & 12001.

Another order for the BR/Sulzer Type 2 was placed, a further 37 went into the order books, nineteen for the Scottish Region, fourteen for the London Midland Region and four for the North Eastern Region. They would be numbered D5114 - D5150 and were scheduled to be built at Derby.

April construction had reached D3771, D5019 and D5 and the names for D1 - D10 had now been published, this Class of ten would quickly become known as the Peak class. In the Works were ED4, ED5, 10202 & D5714. Moved to the Klondyke sidings were 10100 & 10800.

During May the shunter construction had reached D3773, frames were laid for D5 & D6, D5019 was still the highest numbered Class 24 on the Works. The first of the Peak's, D1 was now complete. Locomotives under repair included ED4, ED5, D5702 & 10202.

By early July shunter construction had reached D3783 and Derby's second order of Class 24's had reached D5023. Some of the stored steam locomotives on the Works premises had been there for over a year whilst most sidings around the Derby area were host to many other withdrawn steam locomotives. And gradually these locomotives were towed away to private breakers.

There was little change in the Works production as August began, possibly due to the Works holiday break in July. The shunters had reached D3786, the Class 24's to D5025 and D6 was still the latest Class 44. 10800 which had been dumped at Derby Works for a while was withdrawn at the beginning of August.

The Works Open Day on August 29th featured the following locomotives on display in front of the office block: 70004 William Shakespeare, 92165, D2 Helvellyn, D5021 & D3782. Diesel production still consisted of three types, the Class 08 shunters, the Class 44's and the Class 24's. Derby had just completed its initial Modernisation Plan order of twenty Type 2's, being built now were the next ten D5020-D5029. The Works were still heavily involved with steam repair, but as a sign of the times long lines of withdrawn steam locomotives could now be found not only on the Works premises but also alongside Derby Midland station, in St Andrews Goods yard, at Chaddesden and Spondon Jct. In all almost one hundred steam locomotives could be found at these locations, and the vast majority would be towed away to other locations for scrapping.

September saw shunter construction up to D3792, Class 24's as far as D5027 and work on D7 was well underway.

By October Derby's second order for Class 24s was complete with construction commencing on D5029, the shunters had reached D3796 and work on D8 was progressing well. Visitors to the Works included D5719 & D8210 on test.

During November Derby was well into its third order of Class 24s with D5066 - D5068 under construction, elsewhere work had already started on the last of the Class 44s, D10. Additionally Derby's shunter order ending with D3802 was complete with the laying of the frames for the last of the batch followed by several for the next order numbered D2277 starting with D3937. Repairs included ED6, whilst D8211 had arrived for acceptance testing.

December saw the Works moving along with its third Class 24 order, construction had reached D5070, whilst D10 was almost complete, but there was little change with the shunter order. The variety of diesels under repair continued to grow, those present included ED6, 12093, D5705, D8002 & D8209 to mention afew. The great variety of locomotives under repair continued with the likes of 10000, D2220 & D2901 during February.

![]()

Principal Sources Used in no particular order:

Diesel & Electric Disposal; A Butlin, Coorlea Publishing 1987

Diesel Locomotives of the LMS; JWP Rowledge, The Oakwood Press 1975

LMS Diesel Locomotives & Railcars; EV Richards, RCTS 1996

BR Locomotives & Other Motive Power (Combined Volume); Ian Allan - various years

Page added October 22nd 2007.

Last updated November 9th 2024.

Derby Works 1932 - 1950

Derby Works 1960 - 1969

Derby Works 1970 - 1975

Derby Works 1976 - 1980

Derby Works 1981 - 1983

Derby Works 1984 - 2007