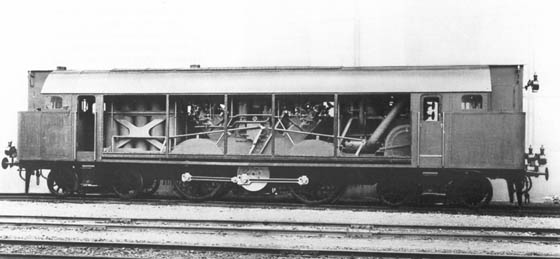

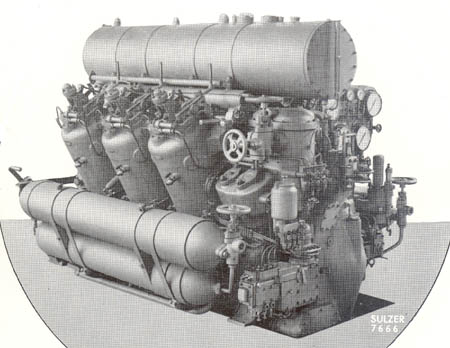

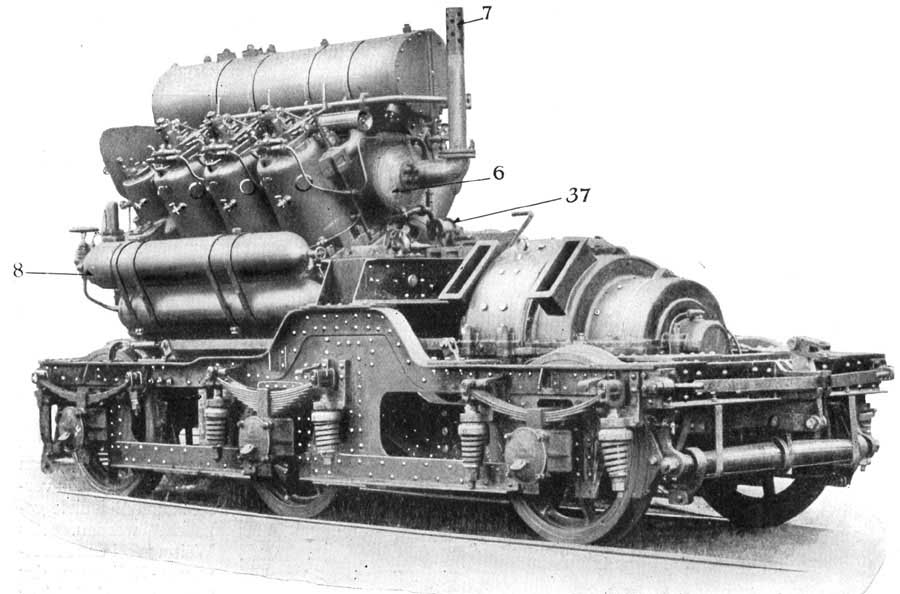

Presumably a manufacturer's photograph taken upon the completion of the 4-4-4 Thermo-Lokomotive showing some of the internal workings of this interesting but unsuccessful machine. The bank of compressed air bottles are on the left with the engine dead centre and the auxiliary equipment (compressors & motor?) to the right.

The first diesel engine supplied by Sulzer Brothers for rail traction was for the unsuccessful 'Thermo-Lokomotive' built by Borsig under their works number 7409/1910. It had been ordered in 1909, but because of the challenges in completing the locomotive it was not available for testing until September 1912. The Thermolokomotive Company was a partnership involving Sulzer Brothers, Rudolf Diesel & Adolf Klose with much assistance from Adolf Brunner & Robert Sulzer.

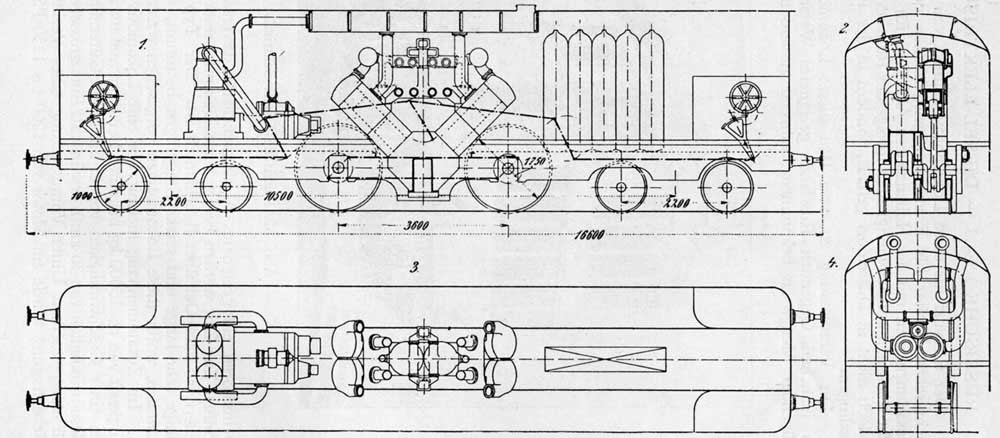

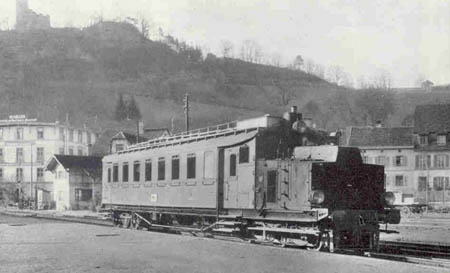

The engine was a valveless two-stroke 1,000hp V-four 4LV38. This direct-reversing engine drove two axles directly through coupling rods on disc cranks on the ends of the crankshaft. Trials took place during 1912 but almost immediately the engine cooling system proved unsatisfactory, the locomotive returned to the Sulzer works for modification. Further tests commenced in March 1913 on the Winterthur - Romanshorn line, they proved satisfactory because at the end of March the locomotive began a four day journey to Berlin, under its own power, but mostly running as a light engine. It did assist on two goods trains, reaching a maximum speed of 70km/h.

In Berlin the locomotive was sent to the Grunewald Testing station during May 1913. During testing the 'Blindwelle' (the link between the engine and wheels) broke, it took six months for this to be replaced. Trials recommenced in February 1914 making half a dozen test runs with loads up to 200 tons. The locomotive's lack of power was such that the testing station would not increase the trailing load above 200 tons for fear of the locomotive failing on the main line. However during the first week of March a cylinder cracked, the testing was stopped, the locomotive was not repaired and scrapped soon after. The start of World War One in August 1914 ended further research for the duration of the war.

The locomotive was a 95 ton 2-B-2 (or 4-4-4) with a cab at each end. Starting was by means of compressed air provided by a bank of cylinders charged by an air compressor driven by a 250hp motor. Once approx 7mph had been reached fuel replaced the compressed air in the cylinders. In service the cut over from air to diesel was found to be closer to 10km/h. The compressor motor proved to be inadequate in maintaining a sufficient supply of air, particularly when the trials included much stopping & starting. Frequently the locomotive would remain stopped whilst the air supply built up. Severe stresses were entertained by the engine as the air/fuel transition occurred, fractured crankshafts and cracked cylinder covers were frequent. Fuel consumption was high and the locomotive was considered very noisy.

With the failure of the Thermolokomotive the First World War stalled continued research by Sulzer Brothers in the application of large diesel engines for rail traction. However modest research continued with the development focused on the experience gained in the petrol-mechanical & petrol electric railcars.

![]()

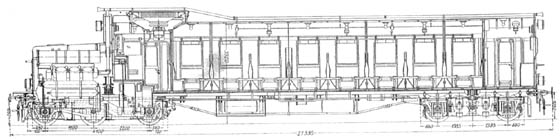

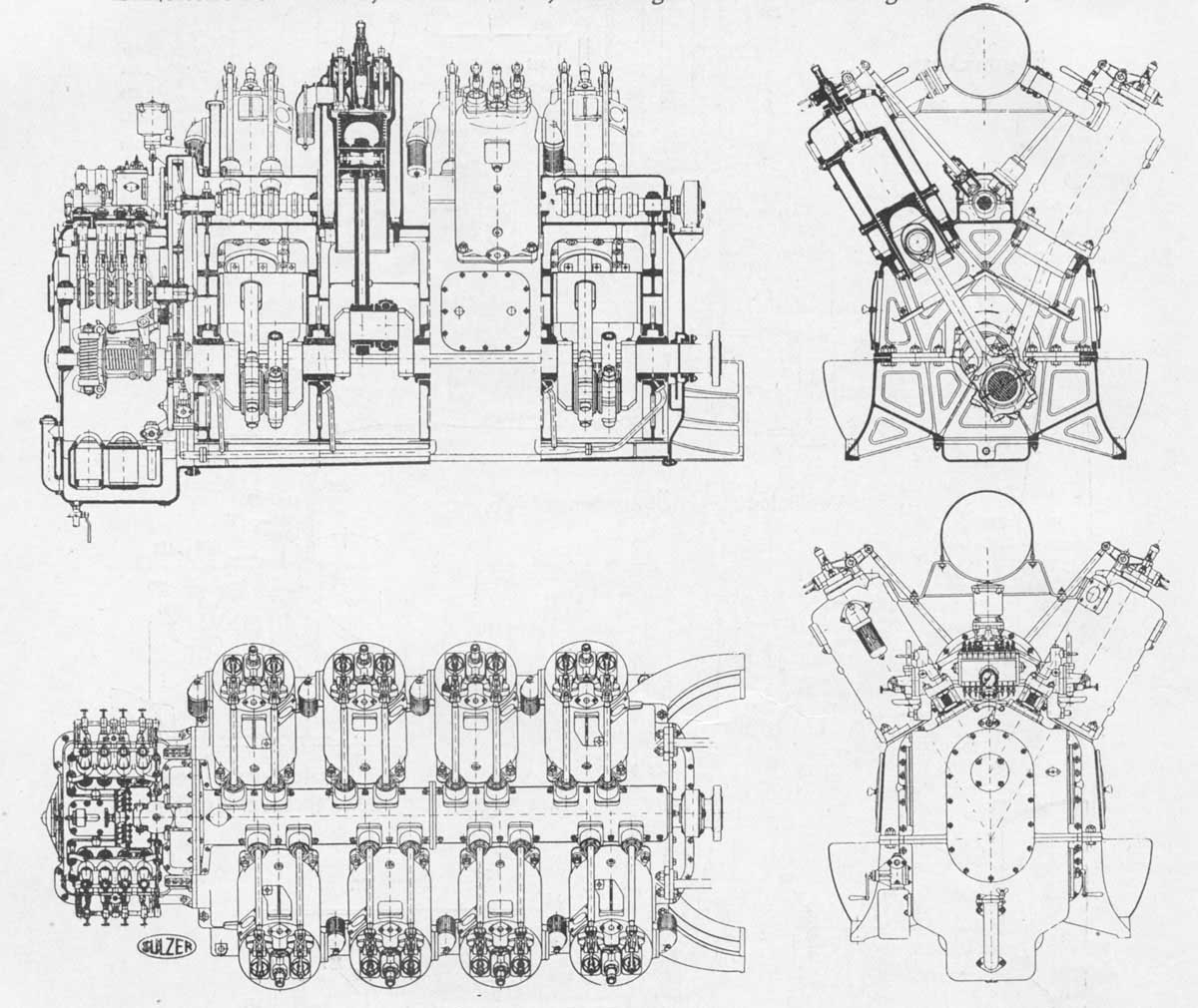

The result of entering the railcar market which required smaller, more compact engines than Sulzer had been used to building led to the development of an eight cylinder four stroke air-blast 'V' engine providing 200hp at 440 rpm. Five diesel electric railcars were provided to Prussia & Saxony in 1914. After the war the engines were converted from air-blast to solid injection.

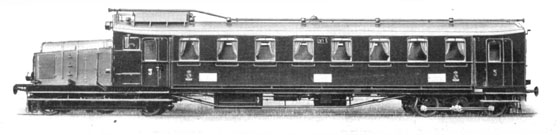

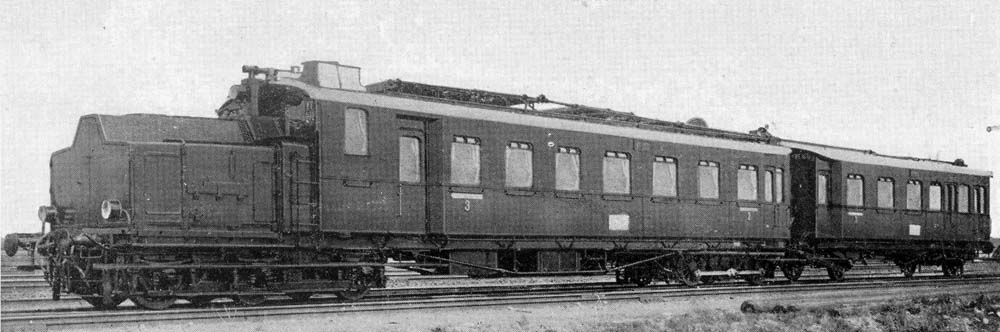

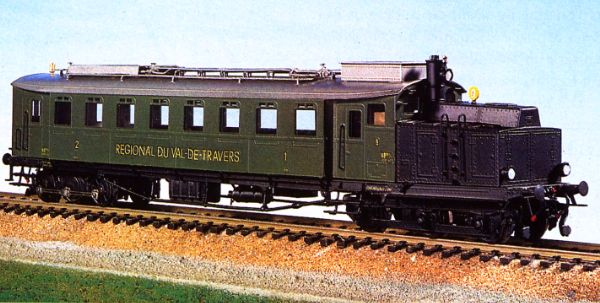

Two of the railcars were eventually bought back by Sulzer, the cars were rebuilt, with numerous detail alterations to the engine and structure, the two being sold to the Val De Travers Railway in 1923. Electric starting replaced the air start, the main generator being used to motor the engine.

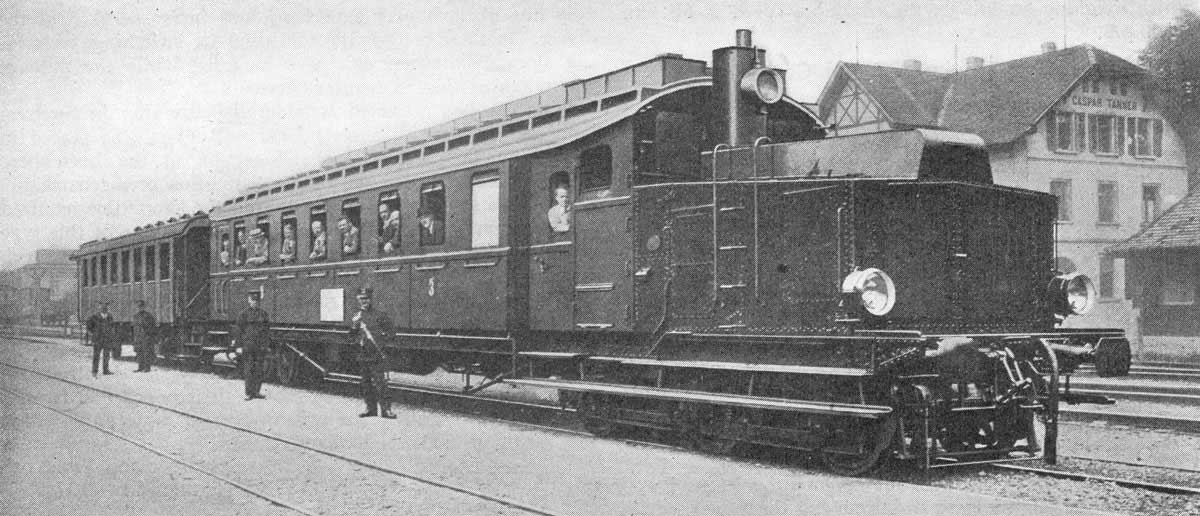

The railcars ran on bogies of two and three axles to carry the weight of the railcar and all its equipment. The three axle bogie carried the weight of the engine and generator whilst the smaller two axle bogie carried the weight of the two traction motors and the cranks and coupling rods that transmitted the power to the wheels. The total empty weight of the railcar was 66.5 tons, 38.65 tons carried by the three axle bogie and 27.85 by the motor bogie. Overall length of the railcar was 65ft 11in.

When running alone the railcar could reach 70kmph, with trailers weighing about 30tons the maximum speed was reduced to 60kmph. Operating at average speeds the railcar had a range of about 500km (300 miles).

Trial runs were completed on the Wallisellen - Winterthur - Romanshorn line, on test a maximum speed of 75kmph was reached from time to time. It was possible to stop the diesel engine completely when not needed on the down grades. The railcar also spent a month in service on the Baden - Wettingen - Niederglatt line with its many steep gradients. On this route the fuel consumption fell 15% as the drivers became familiar with the operation of the engine.

The two railcars that went to work on the Val-De-Travers Railway were certainly not overtaxed by their low speeds and the infrequent service demanded by the timetable. Information from their operations during 1937 reveal a combined total mileage of 58,365km. Since being placed in service BCm8 had run a grand total of 360,509km (daily average of 83km) and BCm9 373,873km (daily average of 87km). During 1937 the railcars had been out of service for a total of 120 days for running repairs & maintenance.

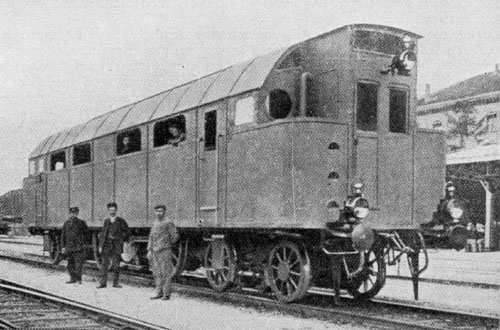

A fine view of the refurbished railcar, now equipped with a new & improved engine and upgraded Brown Boveri electrical equipment. The view shows the railcar attached to a trailer, a frequent occurrence in regular service. From a Manufacturer's photograph.

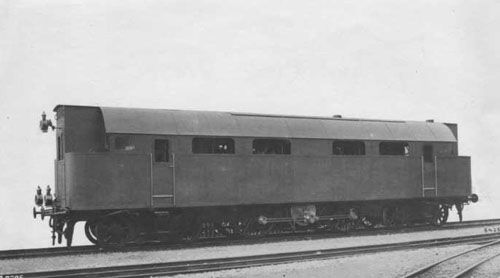

A view of the other side of the railcar, when compared to the view above. From a Manufacturer's photograph.

The Val de Travers diesel-electric railcar in the snow with two trailer coaches. From a Manufacturer's photograph.

![]()

One of the 6LV26 engined 200hp railcars from 1914 survived into preservation and is seen here in 2003 at a museum in Lucerne. (From a photograph by T B Kohler)

![]() Sources:

Sources:

Verbrennungs-Motor-Lokomotiven und Triebwagen, Franco Jabrijn, 1932

Moteurs Diesel Sulzer; CMC/Sulzer June 1933 (French)

Sulzer Technical Review No.1B of 1933 - special edition for the International Railway Congress 1933.

Various Railway Gazette/Diesel Railway Traction

Railway Gazette August 4th 1939

Diesel & Electrics Special Edition No 1; Locomotives International Publication, Paul Catchpole Ltd ISBN 1-900340-16-X

Page added September 19th 2003

Page updated December 15th 2011.

Return to Sulzer page

Return to Picture menu