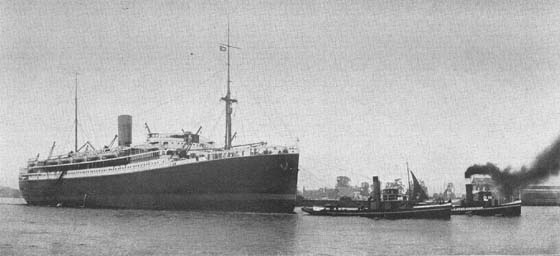

The Pieter Corneliszoon Hooft was built by Société des Ateliers et Chantiers de la Loire, St Nazaire, France under yard number 256. Although Dutch firms also tendered for the ship the contract was awarded to the French on the basis of cost. At the time of construction this ship was the largest & highest powered motor ship built or under construction in France. The ship was launched in 1925, but prior to completion a fire on Christmas Day 1925 severely damaged her passenger accommodation. The ship was moved to Amsterdam in order to repair the fire damage as quickly as possible. She was delivered to her new owner Stoomvaart Maatschappij Nederland during 1926, making her maiden voyage on July 26th 1926, arriving Singapore on September 29th. The Stoomvaart Maatschappij Nederland (Nederland Steamship Company) had recently converted the Bintang, a large cargo ship from steam to diesel power, using a 3,600bhp Sulzer engine. Its success had led to Sulzer engines being installed in the Pieter Corneliszoon Hooft, and shortly after in the Christiaan Huygens.

The Pieter Corneliszoon Hooft was intended for use on the Amsterdam - Java service and would be the second large motor passenger liner to operate under the Dutch flag - the Rotterdam Lloyd 'Indrapoera' would be the first. Ports of call for sailings during 1928 included Amsterdam, Southampton, Algiers, Genoa, Port Said, Suez, Colombo, Sabang, Belawan Deli, Singapore & Batavia. Homeward bound voyages included Colombo except during late May-mid August, when it was an optional stop. The fuel oil capacity of the ship was sufficient to complete one round-trip without refuelling. About six hundered passengers could be carried, interchangeable 1st & 2nd class and 2nd & 3rd class cabins created flexibility, whilst accommodation for 130 servants was available. The smoking saloon, gymnasium and nursery were on the boat deck, the promenade deck included the first class music saloon, a smoking room and verandah, with similar provision aft for 2nd class passengers. The dining saloons were on E deck, a gallery separated the 1st class (208 seats) from the 2nd class (274 seats). The decoration of these spaces represented a variety of modern Dutch ideas.

Large cargo holds were situated forward of the oil bunkers and aft of the engine-room, with a capacity of about 10,600 tons. Above the oil tanks were located luggage and mail rooms.

1926, September 29th: arrived at Singapore whilst on its maiden voyage from Holland to the Dutch East Indies.

1926, October 26th: on its return maiden voyage the ship stopped in Singapore and hosted a shipboard luncheon in celebration of the ship entering service. To a group of about 200 the Captain apologised that time had not permitted the luncheon to be held on the outward voyage.

1927, October 28th: at Singapore, from Amsterdam for Batavia.

1927, November 18th: at Singapore for Amsterdam.

1928, May 10th: at Singapore from Amsterdam for Batavia.

1928, November 22nd: at Singapore from Amsterdam.

By late 1928 the ship had completed six round trips covering more than 105,000 miles, always on schedule and without any mechanical problems. Advertised fares for the spring of 1929 from Singapore were to Southampton 1st Class $825, 2nd Class $568, Amersterdam & Rotterdam 1st Class $850, 2nd Class $586. A 25% rebate was available if the return trip was made within 12 months.

1929, March 22nd: at Singapore for Amsterdam.

From May 1929 through January 1930 the ports of call included Amsterdam, Southampton, Algiers and Genoa with the eastbound voyages terminating in Batavia.

1929, June 6th: arrived Singapore from Amsterdam for Batavia.

1929, June 28th: at Singapore, for Amsterdam.

1930, May 5th: at Colombo, seven passengers left behind as ship sailed, later contacted by wireless and returned to harbour entrance to meet the missing passengers.

1930, July 3rd: arrived Singapore from Amsterdam.

1930, July 25th: timetabled departure from Singapore for Amsterdam.

1930, October 29th: depart Batavia for Amsterdam.

1931, May 30th: departed Singapore for Amsterdam.

1931, October 24th: expected at Singapore from Amsterdam.

1931, November 13th: timetabled departure from Singapore for Amsterdam.

After four years in service the ship was considered too slow and consequently taken out of service to allow for modifications to be made which included the installation of new, larger engines built by Sulzer, Winterthur. Two nine cylinder engines, with cylinders 760mm x 1,240mm, producing 4,000 bhp each at 130rpm were to be erected on the same foundations as the original engines. Two fuel tanks on each side of the forward end of the engine-room were cut away while the engine seatings were strengthened. The scavenging was changed from electrically driven turbo-blowers to engine driven pump scavenged, the cooling pumps were changed to a higher capacity. These changes increased the plant weights from 824 tons to 1,407 tons. The Rotterdamsche Droogdok Maatschappij (Rotterdam Drydock Company) lengthened the hull by 9 feet adding a raked stem to reduce the bow wave, her new maximuum speed would now be 17.5 knots, comparable to the new motor ships being built for similar service. The funnel was also altered, including the fitting of the spark arrestor within the structure. Sixteen weeks had been alotted for the work however delivery would be made a week early. During trials one of her propellors broke. The engines removed from the ship were installed into two company cargo steamers, the Saparoera and the Salawati, both built in 1920 and originally equipped with triple expansion engines.

Advertised fares for the summer of 1932 from Singapore were to Southampton 1st Class $825, 2nd Class $568, 3rd Class $364, Amersterdam & Rotterdam 1st Class $850, 2nd Class $586, 3rd Class $371. A 25% rebate was available if the return trip was made within 12 months.

1932, February 5th: timetabled departure from Singapore for Amsterdam.

1932, April 29th: timetabled departure from Singapore for Amsterdam.

1932, July 22nd: timetabled departure from Singapore for Amsterdam.

1932, September 28th: arrived Singapore from Europe for Batavia. Under command of Captain Potjer.

On November 14th 1932 the ship was moored at Sumatra Quay, Amsterdam for cleaning and fumigation when a fire broke out. The fire quickly took hold of the ship, in order to prevent the fire spreading to the dockside buildings tugs towed the burning ship out to the compass buoy in the IJ, where she burned for nine days. The ship was too badly damaged to repair, considered a total loss of £670,000 to the underwriters, and on December 6th 1932 she was sold for scrap. Whilst being towed to the scrapyard, she almost capsized, ran aground and broke free from her tow, hitting the harbour wall at Pernis. Another fire broke out and she then sank. The ship was raised, and on December 15th 1932 arrived at Hendrik Ido Ambacht for scrapping.

On November 19th 1932 the N.V. Stoomvaart Maatschappij 'Nederland' issued a report to the underwriters which admitted that the cause of the fire remained unknown. On the morning of Sunday November 13th 1932 the Pieter Corneliszoon Hooft was lying alongside the Sumatra Quay at Amsterdam. There was no cargo on the ship and all the ship's personnel had left pending the fumigation of the vessel, using cyanide powder, by the Municipal Sanitary Service at 11am. The only access to the ship was through the entrance on E Deck amidships, which provided access to the engine room and the well aft on D deck. Company guards monitored the ship to ensure no one gained access apart from the fumigation staff. At 7.30pm that same evening the Sanitary Service allowed access to the ship to permit an engineer and donkey-man to enter the engineroom. One of the dynamos was started, the electric heating heating for the ship was turned on as was the ventilation system, as far as this could be achieved from the engine room. The ventilators in the fan rooms were then put into operation to assist in the de-fumigation process.

At about 11.30pm the guard heard breaking glass on the ship, he climbed one of the dockside cranes to get a better view into the ship and saw fire in what he thought was the gymnasium. He notified the watchman at the gate by telephone. At about 11.45pm the donkeyman in the motor-room smelt something burning. A serious fire was located in the accommodation at the fore end of the bridge deck. The first class music saloon was on fire, but the witnesses could not determine if the fire was also beneath the music room. Shortly after this the lights went out. Although the fans in the saloon were not to operate during the de-fumugation there was some urgency to get the ship into drydock. For this reason the ventilation system in the holds had been activated which was not a normal procedure during the defumigation process. The fire brigade was called and the ship's own firefighting system was activated. The ship had sustained minor damage caused by previous fires in the neighbourhood of the ventilators, these being in the second class smoke room and in some cabins of the office staff and the maitre d'hotel. A minor fire had been noted by Captain Potjer in the switchboard of the lighting system on E deck on a recent trip. The equipment was repaired by the ship's engineer and electrician. The chief purser had also reported a fire on the last voyage, the insulation on the cabling had started to burn in wiring located behind a wooden panel. Likewise a similar event had been reported in the second-class music room and the engineers messroom. Vibration damage was believed to have caused some of these failures. Prior to the commencement of the fumigation the quayside electrician in service of the shipping company disconnected the ship's dynamo on Sunday morning followed by connecting the ship to the shoreside electric supply to provide lighting to the ship during the fumigation. following the completion of the fumigation this witness ensured the ship's dynamo was running prior to turning off the shore supply to the ship. It was noted during an inspection of the ship the the fan ventilators in the holds and thermotanks were already working. The fans in the living accommodation were not yet running. It had been noted that the previous day (Saturday) a fan had run hot in the No.3 hold. A donkeyman moving from the motor room to the separator at about midnight detected a burning smell, further investigation confirmed the presence of fire.

The company of Groeneveld & v.d. Poll who supplied and installed the electrical fittings on the ship advised the fans were of the direct current or alternating current types. The fans in the holds were of the alternating current type, and contained three fuses, should one fuse blow prior to the other two intense heat could generate for a brief period, usually being transmitted to and dispersed by an iron tube. These fans were not situated near the seat of the fire.

The Chief Inspector of Shipping in the Netherlands could not identify the source of the fire due to the level of destruction sustained by the ship. It was however noted that:

The rapidity of the spread of the fire was in part caused by the types of paints, varnishes and other materials used in the passenger spaces of the ship.

Continuous technical supervision of the ship was required at all times.

The ship had ben left technically unguarded for about nine hours.

Use of the fire-resitant doors in the bulkheads and other openings could have mitigated the rapid spread of the fire, but would require a change in the de-fumigation procedures.

A closer watch should be maintained on the fans and ventilators when de-fumigation was taking place.

The responsibility of the Municipal Medical Service needed review when they were in effect fully responsible for the ship during the fumigation process and thereafter.

A fire was reported on the hulk of the ship on January 14th 1933, presumably whilst the ship was being dismantled. A strong breeze rapidly fanned the flames, which are reported to have damaged the engines which had survived the earlier fires.

The steamer Johan De Witte replaced the Pieter Corneliszoon Hooft on the Amsterdam - Batavia service.

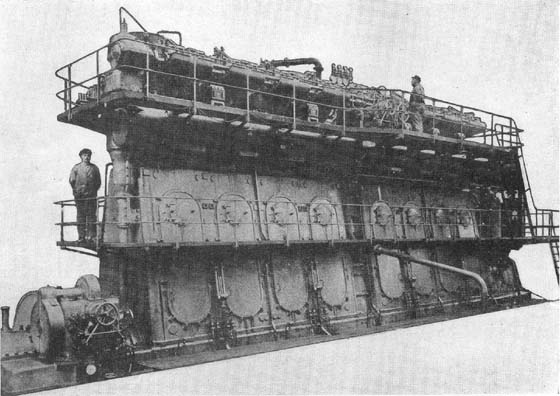

A view of one of the two 8-cylinder two-cycle, single-acting engines built for the P C Hooft. The engine was rated at 4,000hp at 100rpm. Similar pairs of engines were installed in the Bibby Line passenger vessels 'Cheshire' & Shropshire', although these engines ran at the slightly higher 110rpm. Under construction at the same time were four similar engines for two new vessels ordered by the Grace Line, two quadruple screw vessels ordered by NYK Ltd, two for the Hamburg American Line and one for the Anglo-American Oil Co.

Details

Built: Société des Ateliers et Chantiers de la Loire, St. Nazaire - Yard number: 256

Launched: 1925 at St Nazaire, completed July 1926 at Amsterdam

Tons: 14,729 gross

Length: 525ft, then 534ft after 1931 rebuild

Breadth: 68ft 1in

Draught: 35ft

Propulsion (1925 - 1931): 2 x 8-cylinder two-cycle Sulzer Winterthur diesel engines totalling 8,000hp at 95rpm (760mm x 1,240mm)

Propulsion (1931 - 1933): 2 x 9-cylinder Sulzer diesel engines 14,000hp

Auxiliaries: 2 x 520 bhp Sulzer two-cycle engines at 180 rpm coupled to 2 x 325 kW generators (all on port side).

Auxiliaries: 1 x 120 bhp airless injection Sulzer engine driving a 70kW dynamo (on starboard side).

Screws: 2

Speed: 16 knots, then 18 knots after 1931 rebuild

Passengers: 284 1st class, 238 2nd class, 34 3rd class

Crew: 300

Home port: Amsterdam

Resources:

Singapore Newspapers/National Library Singapore Archive.

Busch-Sulzer Marine Diesel Engines

Sulzer Technical Review, No. 2 1928

Page added October 9th 2010.

Last updated January 21st 2014.

Return to Ship menu

Return to site menu