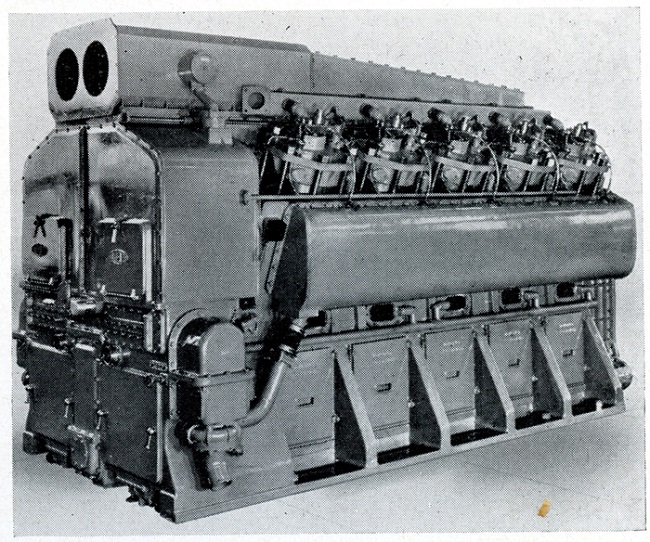

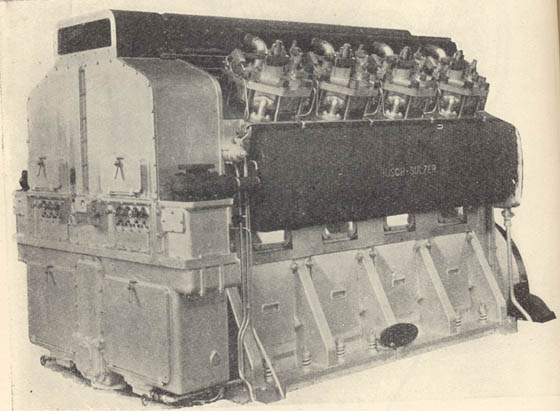

A 1936 2,000hp Busch-Sulzer demonstrator, ICRR 9201, powered by a two-stroke ten cylinder V engine, producing 2,000bhp at 550rpm. Maximum speed was 60mph, maximum tractive effort was 103,200lb at starting, 36,500lb continuous at 16.5mph, weight in working order was 154.5 tons. General Electric built the locomotive and provided the main generator and the six traction motors. The locomotive was equipped with 'V' engined 10 cylinder diesel engine supplied by the Busch-Sulzer Brothers Diesel Engine Company (see image below).

This locomotive was one of three demonstrators supplied to the Illinois Central Railroad, the second was built by Ingersoll-Rand, utilising two of their 900hp four-stroke engines direct coupled to two International G.E.C. d.c. generators which provided power to the tractions motors. Maximum speed was 60mph, maximum tractive effort was 80,000lb, weight in working order was 143 tons. A third locomotive was powered by two Winton engines providing 1,800hp total.

The three locomotives were all scrapped by June 1947.

![]()

The Early Years - Busch-Sulzer of St Louis, Missouri.

On October 9th 1897 beer magnate Adolphus Busch of St Louis, Missouri signed a licence agreement with Rudolf Diesel with rights for building diesel engines in the USA and Canada. Following on from the agreement Busch founded the Diesel Motor Company on January 4th 1898 in New York.

In 1902, a successor company to the Diesel Motor Co was created by Busch and the International Power Company, namely the American Diesel Engine Company. In 1908, Busch acquired all assets of this company and became its sole proprietor moving the company to St Louis.

On December 7th 1910 Adolphus Busch and Sulzer Brothers entered into an agreement to form a joint venture as a successor to the American Diesel Engine Company. Rudolf Diesel joined the venture in the following year, so creating the Busch-Sulzer Brothers-Diesel Engine Co. Busch contributed his American Diesel Engine Company interests, Sulzer assigned their US and Canadian rights together with drawings for two- and four-stroke engines, and Diesel contributed his US patents. A licence was granted to the new company by Sulzer Brothers in April 1911.

The engines built by Busch-Sulzer appeared to have relied little on Sulzer designs. They were designed in the USA, though based on Sulzer patents. Busch-Sulzer concentrated on diesel engines for the marine & stationary power plant (public utility) markets. During World War One the US Navy Department asked Busch-Sulzer to design & construct several types & sizes of diesel engines, upto 2,500hp, for use in submarines. Such was the demand that the entire plant was turned over to this task during World War I.

The Sulzer licence expired in 1926, though the involvement of Sulzer in Busch-Sulzer may have ended well before that date. After 1926, the Busch-Sulzer engines cannot be regarded as Sulzer engines. The name of the company, however, has long led to the misconception that there was some connection, especially as Busch-Sulzer was still actively building diesel engines until 1946 when the company was bought by Nordberg.

(In normal practice, engines are referred to by the names of "licensee-licensor" joined by a hyphen. Thus it is easy to see how confusion can creep in when the US company name was "Busch-Sulzer").

Busch-Sulzer only started developing and building rail traction engines in 1932. The company supplied an engine in 1936 for the experimental diesel-electric locomotive which is featured at the head of this page, though it must be clearly pointed out that the only Sulzer connection to this locomotive was the 'Busch Sulzer' nameplate carried by the power unit (see picture below).

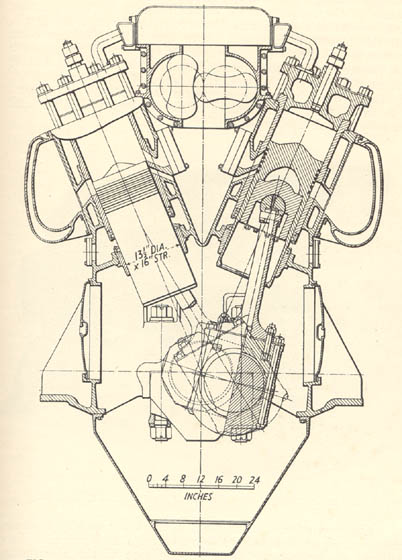

At the end of 1933 Busch-Sulzer Brothers-Diesel Engine Corporation USA produced an eight cylinder two-stroke V engine of 1,600hp followed by a ten cylinder unit developing 2,000hp. The cylinders have a bore of 13.5in and a stroke of 16in, the rated speed is 550rpm. The crankcase and cylinder block are formed in a single casting, a large sump is attached underneath. The portion of the cylinder block located between the two cylinder banks serves as a distributing reservoir for the scavenging air, the blower is mounted above this. Please note that this power unit bears no resemblance to any Sulzer Brothers power unit supplied for rail traction purposes.

Demands of a similar nature occurred during World War Two, with diesel engines being supplied for use by the Army, Navy & Merchant Marine. In 1946 Busch-Sulzer was acquired by the Nordberg Manufacturing Company, Milwaukee, Wisconsin.

None of the other Sulzer licensees in the USA employed their licence for rail traction engines:

* 1935: ALCO's licence was for marine and stationary engines but had

an option for traction engines which was not taken up.

* 1964: Nordberg, though no engines appear to have been built under

that agreement.

* 1976: Westinghouse signed an agreement but never took up production

* 1980: Waukesha used the licence for stationary engines.

![]()

1974: a demonstrator with a 6LDA28B engine

In 1974 one Faur LDH 125 locomotive was shipped to the United States of America as a demonstrator model. This was intended to be the forerunner for an order for a further twenty five similar locomotives to be exported to the U.S.A. However this never materialised which is probably not surprising considering the competition that this locomotive was up against in the land of EMD & GE. Even if the 6LDA28B engine had found favour with those testing it, the locomotive's hydraulic transmission certainly would be a leap of faith for those willing to operate the locomotive.

The locomotive carried the lettering 'Quarter Horse' on the striped band along the long hood.

After its initial testing in the Mid-West by the North American Car Company, Illinois, it was acquired by Washington Terminal, being renumbered 78, for use in switching duties in Washington DC. It is reported that due to the light weight of the locomotive, at least by American standards, it was not the greatest success.

It was later acquired by a freight car repair company that operated from the former Lehigh Valley shops at Sayre, PA. It would be scrapped here during the late 1980's.

The Later Years - Sulzer of Winterthur, Switzerland.

In 1970 the development of the Sulzer LVA24, which had been designed purely for rail traction ended. With the merged companies of Sulzer Brothers & Swiss Locomotive and Machine Works looking to develop a new range of engines, the A25/30 moved from the drawing board to reality. The primary focus was on electricity generation in marine and stationary installations. It was also recognised that it might also see use in rail traction. With this in mind the engine characteristics were to include robustness, compactness, high specific output, ease of accessibility to major components, especially those sustaining high wear & tear and economy in construction and operation.

Although the LVA24 development had stopped in early 1970, this engine surrendered many features for incorporation in the A25 design. Standard output was raised from 184hp/135kW per cylinder at 750rpm to 270hp/200kW per cylinder at 1,000rpm, and later 300hp/220kW per cylinder at 1,000rpm.

For the A25 engines destined for use in the USA changes to the basic design included:

* Special matching of turbocharger and combustion system to provide optimum engine conditions up to 300bhp/220kW per cylinder.

* Additional matching of piston, piston rings, liner, bearings etc to withstand the increased service temperatures - cooling water and lubricating oil temperatures up to 100C.

* Addition of special protective devices.

* Addition of free end power take-off.

* Mounting of oil cooler and filter on engine.

* Larger lubricating oil pump.

* Provision of two cooling water pumps.

* Provision of 'traction' governor.

These provisions recognised certain unique operating conditions found in North America that may only occur in a couple of other countries worldwide and certainly were not encountered in Europe. These include:

* Lengthy, heavy trains run over great distances powered by multiple locomotives within a similar power range.

* Operating in regions of high altitude with extremes of climate in many areas.

* The existance of long established diesel locomotive American manufacturers that understood the necessity of standardisation leading to reliability and economy and had well proven off-the-shelf products available.

* Operation of trains on an 'as-required' basis rather than a European style timetable, leading to extended periods of idling as locomotive await their next call to duty. This creates a conflict between fuel economy and the fouling up of engines during long periods of idling.

* Operation in mountainous regions through lengthy stretches of tunnels or snowsheds causing overheating and poor air quality to the the trailing and/or helper units.

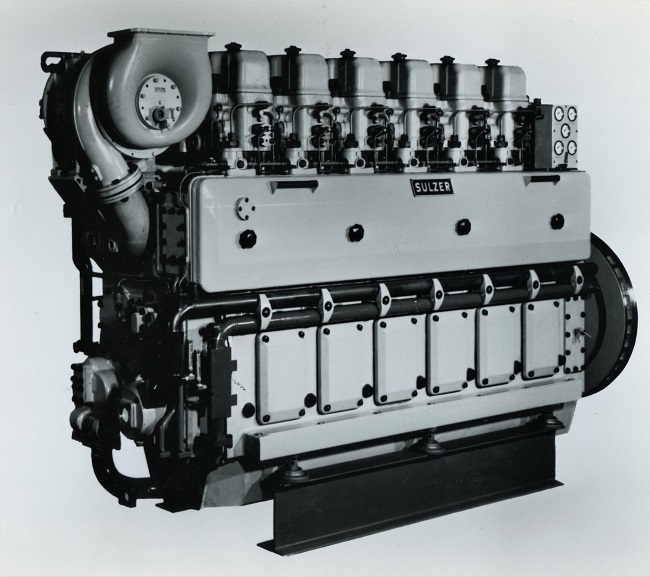

In bringing their products to the USA, Sulzer provided three different engines:

6ASL25/30 one engine for the Morrison Knudsen demonstrator of 1,670bhp/1,245kW at 900rpm with 1,500bhp/1,120kW available for traction.

12ASV25/30 four engines for the Southern Pacific of 3,240bhp/2,400kW at 1,000rpm (rated at 2,800bhp on the Southern Pacific).

16ASV25/30 ten engines for the Union Pacific (UP) and the Santa Fe (ATSF) of 3,600hp/2,645kW at 900rpm.

In general Morrison-Knudsen was tasked with the installation of the engines at their Boise, Idaho facility. This required either complete rebuilding of hulks or an engine installation with only minor bodywork changes.

![]()

Morrison Knudsen, Boise, Idaho

Morrison Knudsen (M-K) had embarked on a search for a replacement of the GE FDL model, the search was of an international nature. Their interest in Sulzer Brothers lay with Sulzer's highly fuel efficient engines and their proven use in the European market. Regretably the use of the Sulzer engines in the USA didn't provide M-K with the success they were looking for and M-K transitioned to Caterpillar engines, generally with more success, although the MK5000 series wound up having many of the same issues as the Sulzers did.

In February 1979 Morrison Knudsen acquired retired Union Pacific GP9 278 (new Sept 1954 - retired May 1978, builders #19875). It was rebuilt using a six cylinder 6-ASL 25/30 1,500hp Sulzer engine and was renumbered MK5001 - MK model TE50-4S. It spent time on lease in Canada, and on the Boston & Albany RR, Conrail, Chicago & North Western, Maine Central & Washington Union Terminal.

The locomotive ended its days on the Morristown & Erie Railroad in 2006, sidelined due to lack of spares, with the engine being removed.

In hoping for success in the USA market Sulzer would have needed an American licensee to build and support the engines. This was obtained by Waukesha for the AT25 in 1981. Primarily this was to allow them to develop a spark ignition gas-fuelled derivative, the ATGL. But at the time (and until 1995), Waukesha was also in the diesel engine business, so presumably could have built the traction version of the AT25. Waukesha did have a nationwide support organization, although it had not been involved with traction applications since the mid-1950s.

That the AT25 was a wet-block engine might have occasioned some resistance. Apparently the UPís biggest objection to Alco locomotives was the fact that the 251 engine was wet block, whereas the EMD and GE engines were dry block, with easily and quickly replaceable power assemblies.

![]()

Southern Pacific

During February & March 1978 the Southern Pacific took delivery of four new four-axle models, the GP40-2, GP40X, B30-7 & MK's TE70-4S. This gave SP the opportunity to evaluate the new Sulzer powered locomotives against similar new machines.

Morrison Knudsen had acquired four retired General Electric U25B units from SP (numbers 6717, 6733, 6745 & 6752), the trucks, frames, traction motors, main generator, cabs and nose would be reused in the rebuild. The long hood was rebuilt ten inches higher, and four inches wider to accommodate the Sulzer engine, giving the appearance of a GP30 over the cab roof area.

The Southern Pacific required the complete installation of standard US components and to be able to work in multiple with EMD & GE locomotives. The ability of MK to marry the old and new components in these units would not be to the satisfaction of Southern Pacific and lead to operating difficulties with the locomotives.

They were fitted with a Sulzer 12ASV25/30 power unit becoming model TE70-4S in MK's terminology.

The engines had cast aluminum pistons, conventional double-bottom cylinder heads, alloy valves with stellite facings working against alloy steel valve seats, a single-piece cylinder block/crankcase of cast iron and aluminum/tin main and big end bearings. It was rated at 2,400 kW/3,240bhp at 1,000rpm/min b.m.e.p 16.3 bar.

The locomotives were outshopped in a striking livery, reminiscent of the 'Daylight' livery found elsewhere on the SP. The 'popsicle' liveried locomotives would spend their careers working out of California & Oregon, the Roseville freight pool being their home depot. This included the mountainous routes through the Cascades to Eugene, Oregon and across the Sierra Nevada to Reno, Nevada, both routes included lengthy tunnels, snowsheds and tight curves. The workings also took them south into the flat and hot San Joaquin Valley.

Regrettably whilst the four locomotives were on their inaugural trip into California during March 1978 SP7032 was removed from the consist, reportedly with traction motor problems

The mountainous routes with tunnel operation saw locomotives encounter high temperatures and poor air quality in the tunnel sections, requiring the engines to be self-protecting when encountering these conditions. When coolant temperatures fell to safe levels the protection systems would allow for power to be restored automatically. These routes also featured low speeds and hours of full power running, leading to high stress loadings, not commonly found with European operators.

These conditions saw changes that provided for larger turbochargers, two-part pistons, traction governors with four 'set' engine speeds, hydrostatic pump for cooling fan drive and increased lubricating oil pump & water pump capacity.

The four TE70-4 engines were fitted with automatic deraters, which allows the engine to be off-loaded in steps to keep exhaust temperature and cooling water within bounds. The device allowed for a higher mean output allowing for higher mean train speeds under the worst conditions of temperature and loading. It was felt that this gadgetry proved its worth.

Special dynamometer car tests were run between Roseville, California & Sparks (Reno), Nevada over the Sierra Nevada mountains, with altitudes reaching 7,000 feet. The engines behaved well but issues with the electrical equipment led to higher rated traction motors being fitted. Shortly after the completion of these tests one engine suffered a piston seizure, caused by a broken exhaust valve. Austenitic valves had been fitted due to the expected high temperatures in the tunnel portions, stem bending became apparent in other positions, a change was made to rotocaps with increased valve stem/guide clearance.

In September 1979 another piston failure occurred and a loose piston crown was discovered. In checking the security of other crowns more bent valves and damaged rotocaps were found. The valve material was changed to Nimonic material for exhaust valves and Ferritic material with Stellite 20 faces for inlet valves.

The method of securing the steel piston crown to the aluminium body was reviewed and the piston redesigned. Originally the crown was bolted from above, a common arrangement, but difficult to check once in service due to carbon deposits etc. A change was made to have the steel crown bolted from below when needed.

Between 1978 - 1980 average mileage was about 140,000 miles. The total operating hours to the end of January 1982 was about 15,000 hours per engine.

A downturn in the economy in the early 1980s saw the MK units taken out of service and put to storage at Eugene, Oregon. The higher level of maintenance required by these units no doubt assisted in the decision to take them out of service. This action also sank any plans for the Southern Pacific to have Morrison-Knudsen rebuild possibly a further fifty U25B hulks with Sulzer engines. Apparently construction of the power units had already begun (by Sulzer or Waukesha?) - these engines would end up in marine use.

Issues affecting the TE70-4S locomotives included:

* Their dislike by many maintenance personnel due to their 'differentness', not helped by their sporadic operation in revenue service

* Maintenance of the cooling system was a time-consuming process. Radiator air was circulated by two sixty-inch cooling fans driven by hydrostatic (instead of electric) motors that received high-pressure oil from an engine - mounted oil pump.

* Cooling system overheating was such an issue that, despite the increased surface area, the Southern Pacific moved the dynamic brake grids from the radiator side inlets to the roof.

* Contamination of lubricating oil.

* New oil filter cleaning concept.

* Different component overhaul concept.

* EMD & GE were unreceptive to having their locomotives re-engined with a foreign prime mover; supply & support for such projects was virtually non - existent.

Late in December 1987 the retired MK units were moved from Eugene, Oregon to Oakland, California following their sale to the Seaborn Towing Company, with their prime movers to be reused in towboats/tugboats. The gutted locomotives then sat in Oakland for two decades before final scrapping in 2008.

![]()

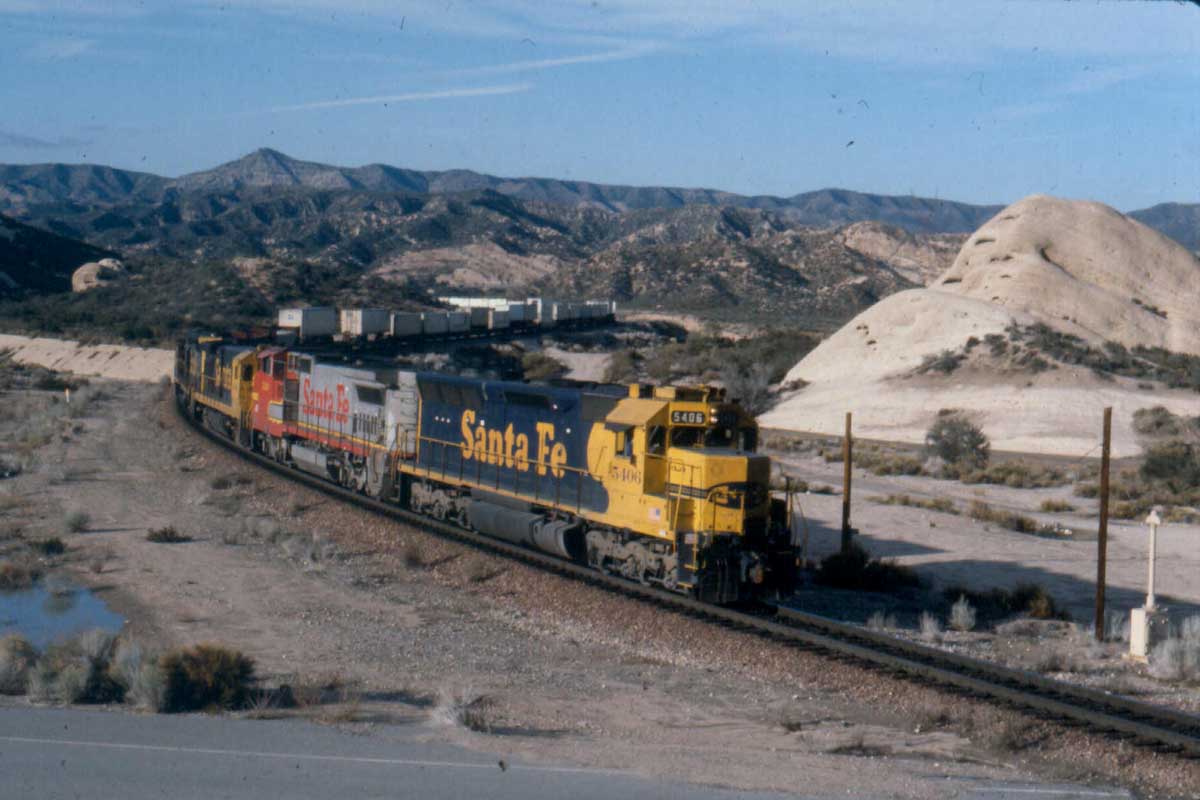

Atchison, Topeka & Santa Fe

Morrison-Knudsen installed a total of ten 16ASV25/30 engines into rebuilds of former SD45 locomotives, four for the Santa Fe and six for the Union Pacific. Although nominally rated at 3,200kW (4,320bhp) at 1,000rpm, the later had to be reduced to 900rpm because of alternator limitations, a gross output of 2,970kW (4,010bhp) was achieved, still allowing 2,645kW (3,600bhp) for traction.

Four ATSF SD45's were selected for the replacement of their EMD 645 V20 power units by Sulzer 16-ASV25/30 power units, rated at 3,600hp. These locomotives were delivered to Morrison Knudsen's facility at Boise, Idaho for the rebuild, they were designated by MK as Model TE83-6S. Much of the remanufacturing work was handled by the ATSF shops at San Bernadino, California, the power units were installed at Boise.

The width of the Sulzer engine required the hood to be widened by about two inches adjacent to the power unit. When released from Boise the locomotives sported Southern Pacific style numbers on the cabsides and number boards.

The locomotives suffered from lack of familiarity, this included the mismatching of the engine with the external lubricating oil system. In conditions of high ambient temperatures and low idling speeds there was insufficient lubricating oil pressure. This led to bearing and/or piston damage, with much of their time spent in the shops. Larger pump capacity resolved the lubricating oil problem. Two returned to Morrison Knudsen for modifications, but the project was soon abandoned and the units stored prior to the re-installation of the EMD 645 V20 power units during 1985.

Whilst in service (1980 - 1985) the locomotives averaged 100,000 - 120,000 miles. After being taken out of service the engines were removed, purchased by a yard/shipowner and installed, in pairs, in two Mississippi pushboats.

| Orig ATSF # | ATSF Re# (4/70-7/70) | Sulzer Rebuilt # & Date | Back to EMD645 config & # | Date to WC RR & # |

| 1815 6/66 | 5515 | 5497 12/80 | 5406 6/85 | WC6596 3/93 | 1830 10/66 | 5530 | 5498 6/81 | 5407 4/85 | WC6597 3/93 | 1841 10/66 | 5541 | 5496 2/81 | 5405 7/85 | WC6595 3/93 | 1851 11/66 | 5551 | 5499 3/81 | 5408 4/85 | WC6598 3/93 |

![]()

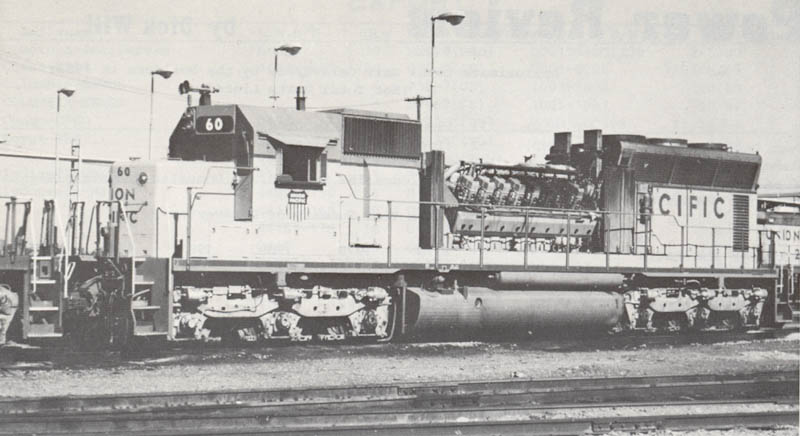

Union Pacific

Of the ten Sulzer ASV25/30 V 16's installed at Morrison Knudsen, it was Union Pacific 60 which was the first to be completed in July 1980. This machine had been stored out of service at Salt Lake City and was moved to MK Boise late in 1979. All bodywork alterations for this machine were carried out by MK, the other conversions were carried out at the UP shops at Omaha, the locomotives then transferred to Boise for final installation of the power units.

As with the ATSF units the hood was widened by two inches to accomodate the larger power unit, the two inches were stepped out at the cab end but tapered at the other end. Because of the location of the two turbochargers the combustion air could not be drawn easily from the clean air compartment. The last carbody door was removed and a new primary air filter was installed. A new wall was installed in the carbody behind the air compressor and the engine air filter located above the compressor to draw air out of the new intake compartment. This alteration was carried out only on the left side of the locomotive.

The locomotive weight remained about the same, as did the horsepower, 3,600hp at 900rpm, utilising the original AR10 generator. The locomotives were worked east to North Platte for painting and renumbering, then back to Salt Lake City for final adjustments by MK personnel prior to entering service. The UP shops at Salt Lake City were the major maintenance point for these machines. The distinctive Sulzer sound was likened to an Alco 251 when under load, the crews liked them for their pulling power. Teething troubles were such that the first five machines by the end of 1981 had been stored at Salt Lake City prior to the delivery of the sixth example, UP65. This last machine remained operational in 1982, serving as an engineering testbed in an attempt by the MK personnel to make the Sulzer's roadworthy in the US operating environment. The continued tests were eventually terminated by MK, UP65 returned to Salt Lake City joining the other five in storage, all were retired in December 1983.

The problems that affected the ATSF & UP units related primarily to inadequate engine cooling and high lube oil temperatures related to the tight clearances of the rotating parts. There was also high usage of aluminium main and rod bearings. To rebuild the engine would cost about $140,000. One feature that received favourable comment was the Sulzer twin turbocharger design, making for a very clean exhaust.

They were eventually moved to Council Bluffs and were later sold to Precision National, Mt Vernon, Illinois in October 1987. They remained here for over ten years, even surviving the bankruptcy of their new owners. National Railway Equipment eventually acquired the assets of PNC, later negotiating a rebuild program that would send remnants of these former Sulzer powered locomotives back to the Union Pacific as SD40-2's. Originally the intention was only to salvage the frame and trucks but the hoods were also retained as a cost saving measure, the distinctive flared radiator cowls easily revealing their heritage.

Whilst in service (1981 - 1983) the locomotives averaged 140,000 - 200,000 miles. Ultimately the engines were sold to a scrap dealer and sold for spares.

| Orig UP # | UP Re# (9/78 - 12/78) | Sulzer Rebuilt # & Date | 1998 rebuild # |

| 3608 | 8 | 64 12/81 | 4749 | 3613 | 13 | 63 10/81 | 4758 | 3614 | 14 | 61 8/81 | 4753 | 3615 | 15 | 62 9/81 | 4756 | 3634 | 34 | 60 7/80 | 4764 | 3637 | 37 | 65 6/82 | 4742 |

Information drawn from:

Diesel's Engine, Lyle Cummins, 1993

Diesel Locomotives & Railcars, Brian Reed, pub The Locomotive Publishing Co Ltd c1938

Extra 2200 South - various issues

Union Pacific Motive Power Review - various years

Southern Pacific Motive Power Annual - various years

Casey Carlson

Union Pacific 1977-1980, George R Cockle, pub Overland Models Inc.

Sulzer Diesel Engines, Sulzer Diesel Engine Division with successor companies.....by B.O.Eckert-Martin 2015.

Steve Palmano - insight & comment

Espee Historic Diesels Volume 5 - Joe Strapac

Page updated May 21st 2023.

Return to Sulzer page

Return to site menu