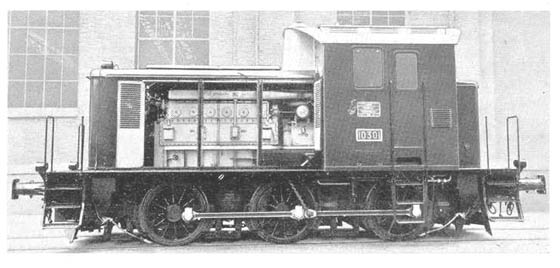

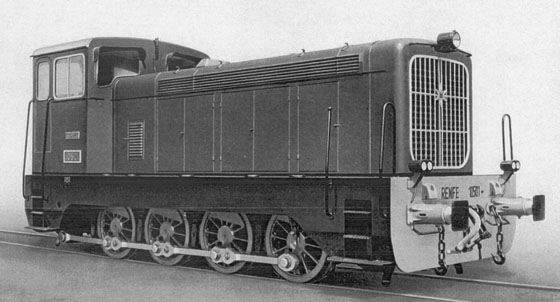

During 1953/54 two Spanish companies, licencees of Sulzer for diesel engines completed an order for twenty 0-6-0 diesel-electric shunting locomotives. The order was split equally between Maquinista Terrestre y Maritima SA of Barcelona & Soc. Esp. Babcock y Wilcox of Bilbao.

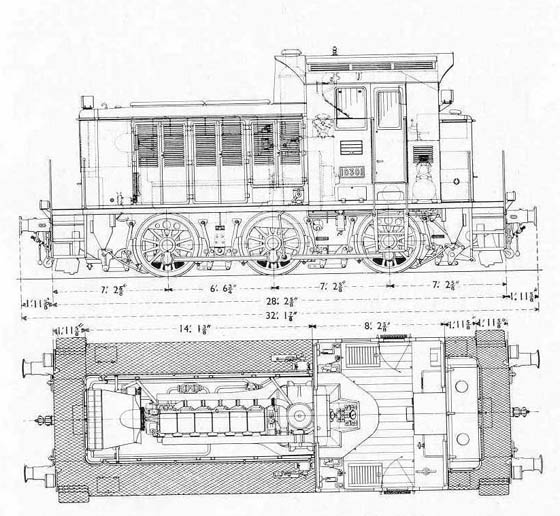

The power unit supplied, a naturally aspirated Sulzer 6LD22 developed a continuous output of 350hp at 870rpm using six 220mm by 290mm cylinders. All the usual Sulzer features were included, except the main crankcase transversals were of mild steel plate rather than steel castings. As usual the underbed supported both the engine & generator whilst tied in finely adjustable main bearings without cap studs in shear are retained. The group was mounted on rubber strips providing some resilience between the group and the locomotive frame. Sixteen of the power units were supplied from Sulzer's Winterthur factory, the two Spanish licensees each built two.

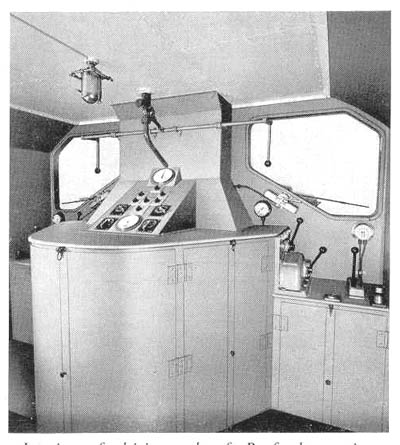

Apart from its electric functions the controller actuated a compressed air regulating valve, used for the control air for the governor. The governor was fitted with a servo-motor for varying the excitation of the generator, additionally it regulated fuel flow.

The main electrical equipment for the first order was supplied by Crompton Parkinson Co Ltd, Chelmsford - principally an eight pole 222kW main generator direct coupled to the engine, a four pole 12kW auxiliary generator recessed into the main machine and two 132hp nose-suspended traction motors driving through Silentbloc resilient gear wheels. The following two orders were supplied by Maqunista, Barcelona & Brown Boveri & Co Ltd, Baden.

A fully welded plate frame structure, inside of the wheels, formed the base of the locomotive. In front of the cab a steel casing housed the engine-generator group, the roof of this casing being fully detachable. Narrower ventilation traps in the roof were also detachable, allowing access to remove the smaller components - cylinder heads, pistons & liners. The main & auxiliary generator projected backwards into the driving control desk. Air for the engine and main generator ventiliation was drawn through a conduit on the back wall of the cab, fresh air coming in from cab roof level was not so tainted with dust & dirt. After passing over the main generator air was ducted to the two traction motors before escaping to the atmosphere. Behind the cab is the battery box, whilst the exhauster and compressor, with their own reservoirs were mounted in their own cabinets against the back weatherboard.

In front of the engine-generator set was a belt driven fan & radiator. The 275 gallon main fuel tank sits between the locomotive frames in front of the leading axle. Cooling water and fuel transfers pumps are compined in one group and driven from the front of the main engine shaft through a V-belt. A thermostat controls the flow of water returning from the engine, either through the cooling group or back to the main tank. The piping arrangement allowed for water to run out of the cooling system when the engine was stopped, avoiding potential freezing damage, yet ensured that cooling was available at all times after start-up.

The two traction motors were mounted on the centre and rear axles, both hung towards the rear. Fully laded the locomotives weighed 48 tons, top speed was 28mph, full output was available up to 22.5mph, though they were principally intended to shunt & haul 500 ton trains upto 12.5mph, though within the continuous rating 400tons could be hauled up 1 in 100 grade at 7mph. Vacuum braking was used for the locomotive and through connecting hoses to the train. Two cylinders working on the cross shaft were fitted at the rear end. A motor driven SLM rotary exhauster provides the necessary vacuum, having a high & low speed, weakening the field of the motor creating the high speed option. The exhauster can be fed either by the battery or from the auxiliary generator. The driver's brake valve was combined with the controller of the exhauster group. Sanding on the outside axles was air operated, powered by a motor driven compressor located alongside the exhauster group in the cab.

The electrical control equipment was provided by Maschinenfabrik Oerlikon.

This original order for twenty units eventually blossomed to a total of 202 locomotives numbered:

10301-10400, 11301-11400, 12301-12302

later 303.001-303.202

Based on an article in Diesel Railway Traction, May 1954.

![]()

During February 2017 10349 was saved from scrapping by the Spanish Railways Foundation (FFE), with its destination most likely the Madrid-Delicias museum. With the Miranda depot holding a considerable number of spares for this Class of locomotive, the possibility of the locomotive being made serviceable was considered. This would greatly assist the museum owners in being able to move museum exhibits within the property without having to rely on an outside contractor's locomotive.

![]()

An improved version of the Class 303, eventually totaling 63 locomotives.

![]()

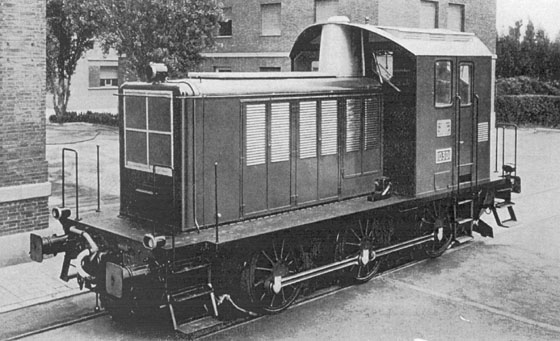

In supplying the Sulzer 6LDA22 engines for twenty shunting locomotives for RENFE some were built at Sulzer's Winterthur plant whilst the remainder were the first to be supplied by Henschel & Son AG after their acquiring a license for that engine. Cylinder size was 8.7in by 11.4in, with an output of 550hp at 900rpm. Sulzer's exhaust -gas pressure-charger was fitted. Starting was by compressed air.

Between the engine & transmission was a drive shaft fitted with two Secheron flexible disc type couplings. The hydraulic transmission was a Voith L37V comprising one torque convertor and two fluid couplings, with the usual driving gears and alternative sets of reduction gears allowing top track speeds of 18.5 or 37mph. Final drive was through a jackshaft & connecting rods.

Combined straight airbrakes for the locomotive & vacuum equipment for the train is fitted, the system being Knorr-vacuum. There are two airbrake cylinders acting on one block on each wheel. The air supply for the brakes also actuates the sanding equipment.

Gauge: 5ft 6in

Wheel Arrangement:0-8-0

Wheel Base: 13ft 9in

Minimum Radius Curve: 330ft (centre axles have side play of 20mm)

Fuel Capacity: 550 gallons

Weight, empty: 57tons, loaded: 60tons

Delivery commenced in 1954, these being the first locomotives delivered to RENFE with hydraulic transmission.

From an article in Diesel Railway Traction, September 1954.

Numbered 10501-10520.

![]()

![]()

Page added January 21st 2003.

Page updated October 30th 2025.