There are many railway lines in the world which present some sort of challenge in running trains over them. For the Caile Ferate Romane (CFR) the well used line between Campina & Brassov presented a multitude of operating challenges. It was heavily used by domestic traffic and carried substantial longer distance international traffic between Bucharest and central Europe. The 75km (44 miles) between Campina and Brassov crossed the Transylvanian Alps (a part of the lengthy Carpathian moutain range) on gradients varying between 1 in 40 & 1 in 50 (2.5%) with uncompensated curves of 900 feet radius. In particular the route north of the summit from Predeal to Timisul De Sus contained many curves. In the days of steam operation two steam locomotives were required at the head of the train and either one or two bankers at the rear, a costly operation in terms of manpower and equipment.

Plans to double track the route, electrify the route or modernise alternate routes were all stifled by the costs involved, leaving the possibility of dieselisation as the only alternate available to improve the working of the route. Specifications called for unassisted operation of 600 ton trains over the mountainous route, with the ability to restart a train on the steepest grade. This suggested an engine output of at least 4,000hp which, coupled to a 20 ton axle loading and eight driving axles meant building a locomotive of two parts to meet all the requirements.

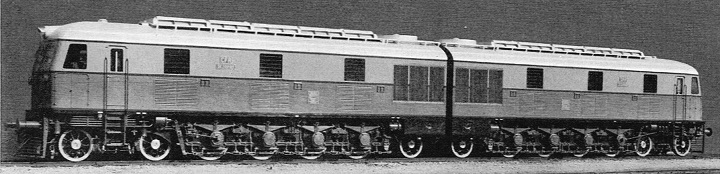

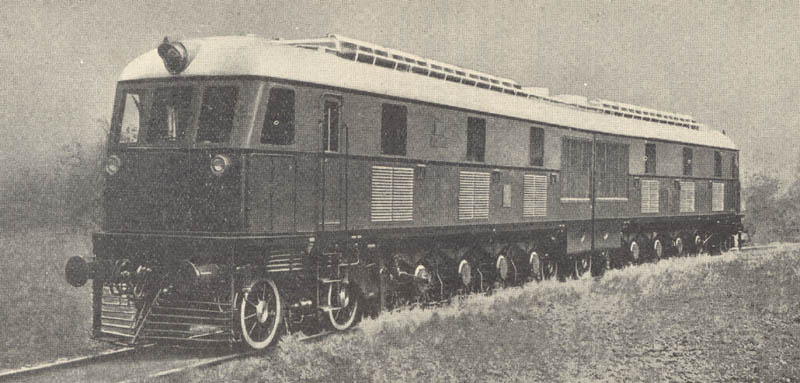

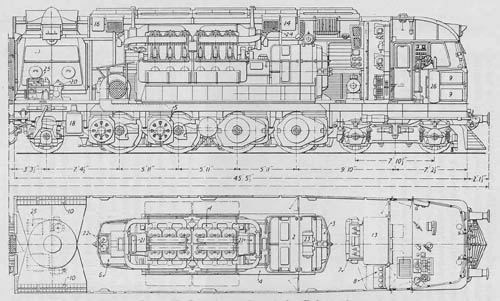

There was an interval of about two years between the placing of the contract and the delivery of the double locomotive to the CFR just prior to the start of World War Two. The finished locomotive had a 2-Do-1 + 1-Do2 wheel arrangement and was powered by two 2,200hp Sulzer engines similar to those fitted in the French PLM double locomotive. It had a maximum speed of 62mph, a maximum tractive effort of 81,500lb and weighed 230 tonnes loaded, 218 tonnes empty. The axle loading was 19 tons. CFR and the builders opted for a 2-Do-1+1-Do-2 wheel arrangement, providing four driving axles per unit and so greater adhesive weight, whilst retaining a total axle count of seven per unit.

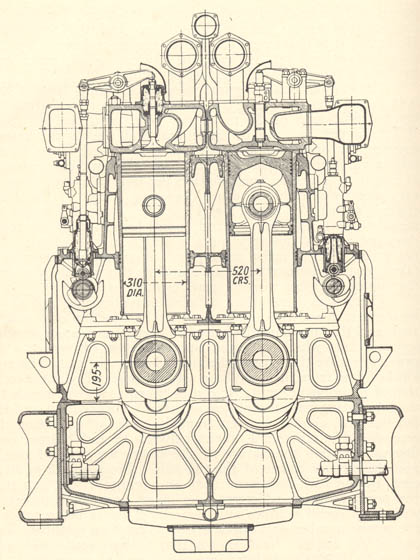

Each 2,200hp engine, designated 12LDA31, had two vertical banks of six cylinders, each with its own crankshaft, which drove a single main generator through spur/step-up gears. The cylinder size was 310mm by 390mm (12.2in by 15.4in) which, with the use of the two Buchi superchargers provided a one hour rated output of 2,200hp at 700rpm. Under test a peak of 2,500hp had been attained for at least two hours without difficulty. The crankcase and cylinder block for the whole engine is in four parts, of cast steel; the cylinder block portion is in two halves, each containing six cylinders (three in each bank), and welded on the transverse centre line to its partner. The crankcase is in two corresponding halves welded together, the cylinder blocks and crankcase portions are bolted to each other. The engine measures 13ft 9in long, 6ft 3in high above the crankcase center line and 3ft 8in below, and 6ft 5in wide.

The empty weight of the engine, including step-up gears and main generator was 21 tons (21.5lb per bhp), with the welded steel underfame added the weight increased to 23 tons.

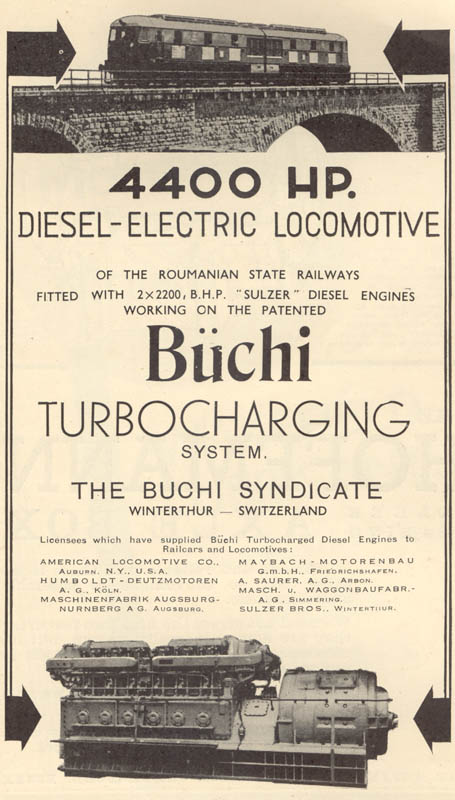

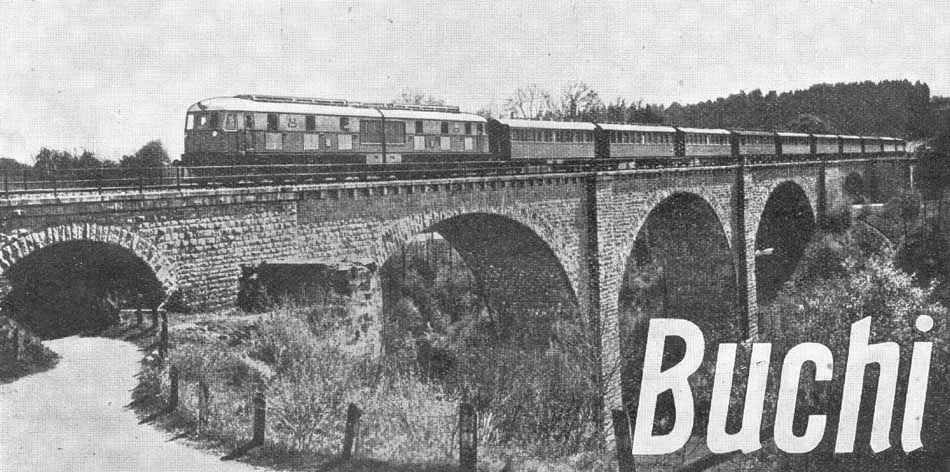

An advertisement from a 1938 railway journal features the Roumanian locomotive in an advertisement for the Buchi turbocharger.

The starting tractive effort for the locomotive was 81,500lb, when operating at the maximum speed of 62 mph and under full power 21,500lb tractive effort was available at the wheel rims which was sufficient to haul a 600 ton train up a straight 1 in 200 grade. For the toughest section of the line the locomotive's output was more that sufficient to maintain 19.5mph with a 600 ton train. The one hour tractive effort rating at the wheel rims was 53,800lb at 20.8mph and 38,400lb at 29.8mph.

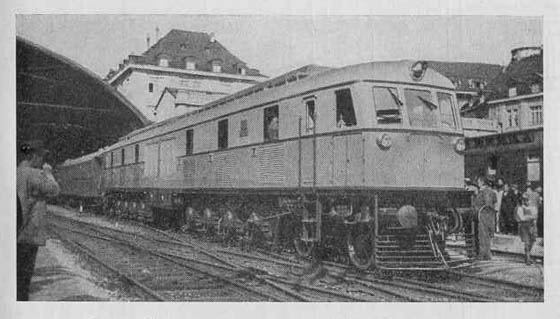

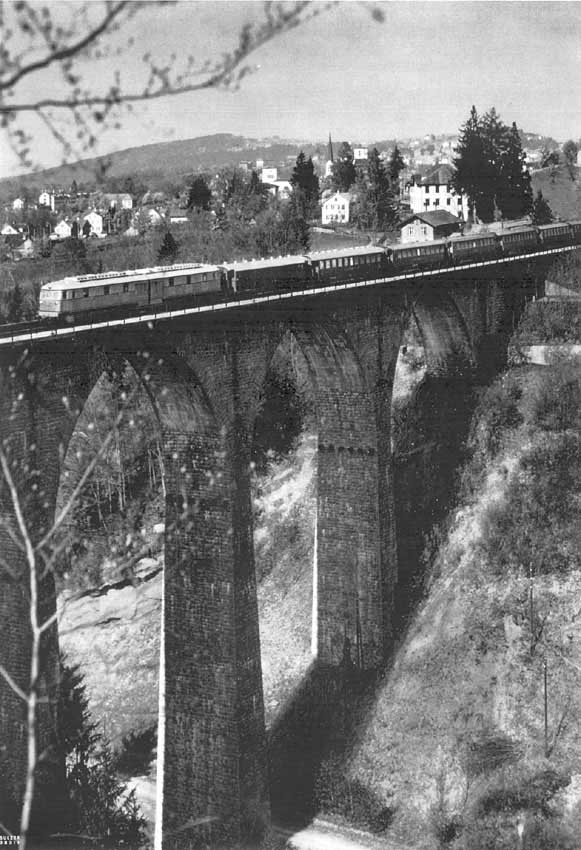

Henschel & Sohn AG, Kassel built the mechanical portion of the locomotive, it was then moved on its own wheels to the Brown Boveri & Co. workshops at Munchenstein (Basle) for the installation of the power and transmission equipment prior to testing in Switzerland between Winterthur & St Gallen. From Winterthur it is 57.5km to St Gallen, mostly up hill with ruling grades of 1 in 100 & 1 in 125, the steepest grade being 1 in 83 for 3km between Gruze & Raterschen. With a trailing load of 300 tons the 57.5km was completed in 45 minutes, which included certain slacks and a top speed of 62 mph.

Acceleration from a standing start over a rising grade and curved route was to:

30 kmph in 35 sec

40 kmph in 46 sec

50 kmph in 58 sec

60 kmph in 69 sec

70 kmph in 84 sec

75 kmph in 91 sec

80 kmph on 98 sec

It was not necessary to use full power for these numbers, with straightline acceleration being maintained to about 70kmph.

Normal starting current for each generator was:

2,000 amp at 400 volts on notch one

2,500 amp at 400 volts on notch two

2,700 amp at 400 volts on notch three

1,800 amp / 1,200 amp at 430 volts on notch four.

Two manufacturer's views of the prototype 2-Do-1 + 1-Do2 locomotive. Internally the locomotive was similar to the French PLM operated Sulzer powered locomotive, but externally the Roumanian machine seems to bear a little of the Swiss influence, unlike the two very stylised French machines. The locomotive was not equipped with any train heating equipment, in cold weather the CFR would allocate a steam heating wagon for passenger trains worked by this locomotive.

The empty weight was 218 tonnes with the service weight as 230 tonnes (226.4 long tons). The adhesive weight was 148 tonnes (145.7 long tons).

The auxiliary electrical system was of 215 volts nominal, using a 128 cell alkaline battery. The control and lighting voltage was 24 volts and fed by a small motor-generator unit.

The control system was of the Sulzer-Brown Boveri type, in this case with a Brown Boveri servo field regulator. 8-step power control was provided. Four engine speeds were used, namely 380, 485, 625 and 700 rev/min. Notches 1 through 3 were of the fixed excitation type at 380 rev/min, notch 4 was fixed excitation at 485 rev/min, notch 5 was of the load control type at 485 rev/min, notches 6 and 7 were load control at 625 rev/min, and notch 8 was load control at 700 rev/min. Thus one-hour rating was available at notch 8, and the continuous rating at notch 7. A key feature of the BBC system was that engine speed and load points were set independently. This allowed a reasonable number of load control notches whilst using a small number of engine speeds.

The Brown Boveri servo field regulator was of the recently released 'new' type, based upon a rotary vane hydraulic motor and using solenoids to set torque levels. In this case two solenoids were used to set three torque levels. It was noted that notch 8, which accessed the one-hour rating of the engine, was used mainly for acceleration purposes. It was readily apparent that the 8-notch power control of the DE241 was much coarser than the 15- and 20-notch controls respectively of the SNCF 262BD1 and 262AD1. To some extent this may have reflected the control systems chosen for each. The Simplex-Secheron (262AD1) and Jeumont (262BD1) systems readily allowed for multiple torque settings with a small number of engine speeds, so it could well have been that multiple notches were provided simply because they could be provided. With the Sulzer system of the time, fewer torque settings were feasible, hence fewer notches. Apart from that, the 262AD1 and 262BD1 probably needed, or certainly would have benefitted from finer control because of their lower adhesive weight, 108 tonnes nominal as compared with 148 tonnes for the DE241. During acceleration, the 262AD1 and 262BD1 would have been operating much closer to the adhesion limit than the DE241. In that situation, relatively small notch steps are needed to minimize the risk of slipping at a notch change. For various reasons, Sulzer moved on to much finer power control systems in later locomotives, and those used in the SNCF 060DA (1954) and CFR 060DA (1959) are illustrative.

The main contractor was Sulzer Brothers, Winterthur, mechanical parts by Henschel (b/n 23549 of 1938), electrical parts and engine assembly by Brown Boveri & Co. After construction the locomotives trialled between Winterthur & St Gallen in May 1938, running up about 1,100 miles under test. The double locomotive was handed over to the CFR on June 16th 1938, with comprehensive tests commencing on July 5th 1938 over the route which they had been designed for. The testing was so successful that after only eight days they were accepted by the railway authorities and introduced into regular service on July 20th 1938.

They entered service on the Bucharest - Ploesti - Campina - Brassov mainline, a total of 105 miles, with the northbound trains facing uphill grades for 89 miles from Bucharest to Predeal (elevation 1,054m), whilst southbound trains faced only the short but challenging 16 miles from Brassov to Predeal. Daily one round trip was made between Bucharest & Brassov with a fast train weighing 500 - 600 tons. These trains made frequent stops providing a greater test of the locomotives abilities. The combined fuel capacity of 8,000 litres ?? (1,760 gallons) allowed for two round trips before refuelling and since the locomotive required no assistance on the mountain grades a considerable number of steam locomotives and their crews could be eventually re-allocated elsewhere. For a round trip with a total train weight of 730 tons (locomotive + trailing load) the fuel consumption averaged 22.9lb per ton-mile gross and 33lb per 1,000 trailing ton miles. Lubricating oil consumption was 0.7lb per 1,000 gross ton-miles

In the early days the locomotive was stopped for one day a week for inspection and the ability to make minor repairs if necessary. By the end of August 1938 the double locomotive had run 9,500 in service for the CFR.

During World War II the double locomotive was stationed at Grivita Works. When the railway station and workshops were bombed during 1944 the local power supply was disrupted. One of the double locomotives was used as an emergency power supply.

From 1946 - 1963 they were allocated to Brasov, being withdrawn from there in 1963. They were placed on display at Bucuresti Calatori depot, later restored in 1994. During 1996 they were moved to Dej Triage depot.

The survival of the twin unit 1938 built 'demonstrator' has to be one of the more charmed stories in the preservation of pre-World War Two diesel locomotives, perhaps just surviving the conflict is remarkable in itself. (Two large views of this machine can be found on the Roumanian page of the European Railway Server).

Builder:

Mechanical portions & bogies: Henschel & Sohn, Kassel

Engines: Sulzer Brothers, Winterthur

Electric Transmission: Brown Boveri & Co, Munchenstein

Brakes: Westinghouse

Compressors: Oerlikon

Radiators: Suddeutsche Kuhler Fabrik AG

Turbo Supercharger: Buchi, exhaust gas

Fuel pumps: Bosch

Oil cleaner: Rameshohl & Schmidt, centrifuge

Battery: Jungner, cadmium nickel

Cab windows: Sekurit glass

Axle boxes: Peyinghaus Isothermos

Flange lubricators: Friedmann

Speed indicator/recorder: Teloc

Window heaters: Royal, electric

Windscreen wipers: Bosch

![]()

Resources:

Diesel Railway Traction June 10th 1938

Diesel Railway Traction October 28th 1938

Diesel Railway Traction January 20th 1939

![]()

More details on the 060-DA Class

Page added July 3rd 2003.

Page updated June 17th 2020.

Return to Sulzer page

Return to Picture menu