In 1935 a design competition was initiated by the PLM for the building of locomotives that could haul heavy (up to 600 tons) passenger trains at fast schedule speeds over its 1100 km Paris-Mentone route without the need for refuelling or other servicing en-route. At this time electrification was not an option, leaving diesel locomotives as the obvious choice. These were specified to be able to develop full power at their highest speeds, and to provide fast acceleration from stops and slacks. It was calculated that an installed power of approximately 4000 hp would be required.

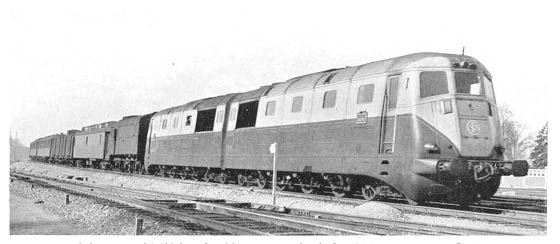

From this competition in July 1938 the SNCF put into service two double locomotives, a 225 ton twin unit diesel locomotive powered by a pair of Sulzer 12 cylinder twin bank engines and a twin unit locomotive powered by four MAN 1,050hp engines.

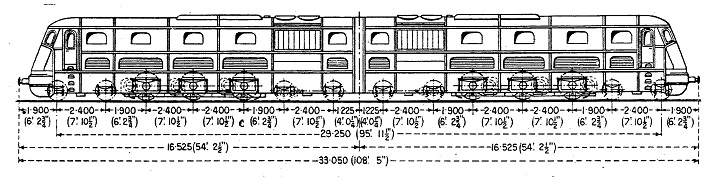

The 1935 timing explains the choice of the rigid-frame layout for the two locomotives. It was a little premature to seriously consider the independent bogie form for what were to be relatively high speed locomotives by the norms of the time. Apparently the articulated bogie form, presumably with pilot trucks, was considered, but was deemed impractible due to the required two engine assemblies. Instead, back-to-back rigid-frame units were chosen. As well as the 18 tonne maximum axle loading, a maximum weight per unit length (over buffers) of seven tonnes per metre was specified. Meeting these two requirements with a single frame locomotive would have been difficult, options might have been 2-Co+Co-2 wheel arrangement or 2-Co-1+1-Co-2 or 2-Co-2+2-Co-2, but length, headroom (reduced floor height to clear framing) and weight were all factors running against a single frame locomotive. The adhesive weight obtained with the chosen 2-Co-2+2-Co-2 wheel arrangement (nominally 108 tonnes) might have been considered excessive by the prevailing standards, but it did help with the starting of heavy trains.

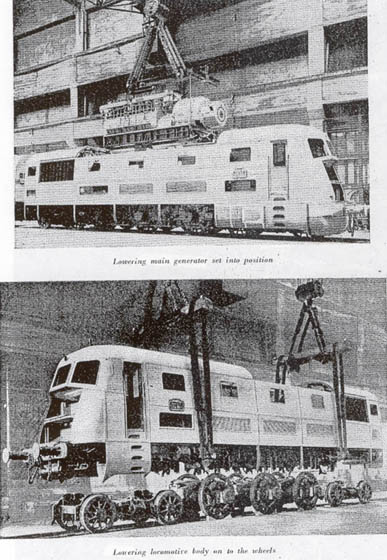

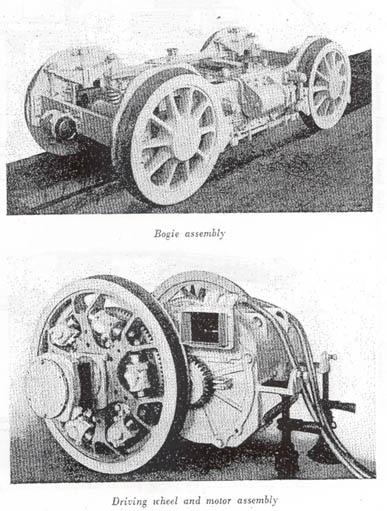

At the time of construction they were the most powerful engines ever installed in railway traction. The 12 cylinder twin bank engines were each rated at 2,200hp at 700 rpm on the one hour rating. Cylinder size was 310mm by 390mm (12.2in by 15.4in). Electrical equipment was supplied by les Forges et Ateliers de Constructions electriques de Jeumont, each half unit having a main generator, three traction motors, an axle driven exciter, an auxiliary generator and other subsidiary equipment. The total of six tractions motors are of the four pole series, with forced ventilation, permanently coupled in parallel. The motors have single armature winding, applying power through two pinions to a quill shaft concentric with the axle turning in pad lubricated bearings forming part of the motor body. The hollow shaft is fitted with two pinions attached by clamp plates. A Kleinow A.E.G. type flexible connection is fitted between the quill & the axle. A ninety cell cadmium nickel battery was fitted for use in motoring the generator and other support systems, split equally in each half unit, located near the cab.

The underframes were built up of one inch thick welded steel plates, with substantial cross braces at the ends and at the bogie pivot points. Less substantial transoms were placed above each motor axle and between the axles to serve as supports for the traction motors. The entirely suspended motors are fixed to the frame by two supports on the side opposite to the axle and by a midway fastening to the upperside of the motor body. The bogies with interior frames and oil boxes have a spherical pivot and are fitted with a centring system of laminated & coil springs in combination. A bogie axle adjoining the central coupling actuates the 6kW nose suspended exciter used to regulate the main generator set.

The lack of train heating equipment in these locomotives was deliberate. It was planned that a heating-boiler van would be used with them during winter months. A separate boiler car could provide a better working environment for the boiler(s), and the reputed unreliability of train heating boilers, at least in the early days, would not adversely affect availability of the then relatively expensive diesel locomotives.

Clearly, the PLM had engaged in some progressive thinking, intending to take advantage of specific as well as general diesel benefits. The chosen power output, 4000 hp, was well judged, too. In the USA in the immediate post-World War Two years the New York Central (NYC) undertook an extensive comparative motive power study, both theoretical and practical. One conclusion was: 'While from the charts, the 4000 bhp Diesel might not be expected to equal the performance of the J-3 steam with its somewhat higher maximum horsepower, even though the Diesel accelerates more rapidly up to 60 mph, actually with trains of fifteen or sixteen modern cars, it has proven more effective in maintaining the fastest schedules between Harmon and Chicago.' Fifteen cars were shown as a 1005 short ton (900 long ton) trailing load, with added drag from the air conditioning equipment. This was greater than the PLM trailing loads, but the NYC route under study was completely flat, whereas the PLM route had a small number of moderate grades, 0.8% ruling.

Another comment from that NYC study was: 'Electric power has the advantage over both steam and Diesel in regaining speed from stops or slowdowns because its excess reserve capacity permits accelerating the train at a much faster rate. As a train-handling unit only, the straight electric is the most satisfactory motive power available, and in this respect it is not expected that new forms herein described, either under development or in use, will exceed it.' Thus, whilst the PLM diesel pair were a step in the right direction, SNCF went one better with its post-World War Two decision to electrify the route.

Service History

The locomotive was originally intended to haul the 'Cote d'Azure' express between Paris and Nice or Mentone, returning the next day with the northbound working. Servicing and traffic reasons quickly found these plans replaced by the locomotive working a return day trip between Paris and Lyons, a daily mileage of 635 miles with average speeds of 56 - 60 mph on 350 - 450 tons trains prior to World War Two. After the war the average speed dropped to 50 - 52 mph but the loadings increased from 560 - 750 tons. The route was mostly undulating but included a continuous rise over eighty miles between Laroche & Blaisy-Bas. After the electrification of the Laroche - Dijon route the locomotive transferred south to cover the Riviera expresses, including the Blue Train, between Lyons & Nice, a return trip of 700 miles every twenty four hours. Due to track conditions existing at the end of the War the locomotive's top speed was limited to 120 kph (75mph), prior to the War 140 kph (87mph) was possible.

Between November 1937 and February 1938 the locomotive covered over 150,000km in regular service, at the end of February 1938 it was required for some special tests. New types of blades were installed in the Rateau turbo charger after the originals failed, for a while portions of the engine operated without pressure charging. Tests revealed that on a curved 1 in 125 grade with a trailing load of 535 tons a speed of 50mph could be achieved in four and a half minutes over 3.5km. A top speed of 60mph under these conditions would be achieved in seven and a half minutes.

Between July 5th 1938 and December 31st 1938 the locomotive covered 112,650km (70,000 miles) on the Paris - Lyon route with trains Nos. 13 & 16. On October 24th 1938 the locomotive entered the shops for a routine partial overhaul, having covered 80,947km (50,000 miles). Fuel consumption during this period averaged 3.24 kg (11.45lb) per train mile after working 500 tons trains with speeds up to 60mph. On a special trip between Paris & Marseilles with a trailling load of 460 tons to Avignon, then 530 tons to Marseilles fuel consumption was 4,750 kg (4.68 tons) over the 1,074 miles. At the 50,000 mile overhaul attention was given to a couple of piston rings, four valve springs, three valve guides and one fuel injector. Four big end and three main bearings were dismantled and were found to be in good condition, because of this the remainder were left in place.

Between July 1938 and the outbreak of war on September 3rd 1939 the locomotive ran 138,000 miles. During the hostilities the locomotive was stored, being recommissioned in June 1945, covering another 490,000 miles up to January 1950 principally on the Paris-Dijon route. It had recently received an intermediate repair, but following an accident it then received a general repair.

Since 1938 it had received three general overhauls and six intermediates. At the 1950 general overhaul the two power units still had the four original carbon-steel crankshafts. Of the twenty four original forged aluminium alloy pistons, only two had been replaced, in the 'B' unit. The cast iron cylinder heads and the fuel injection pumps were all original. A total of thirty two Sulzer fuel injection assemblies were orders as spares to the twenty four in the two engines, allowing for a rotation of these assemblies when cleaning became neccesary.

Each cylinder had one inlet and one exhaust valve, the exhaust valves were all originals, four inlet valves had been replaced, one in the 'A' unit and three in the 'B' unit. Before the War two split pins from the big-end bolts were found in the sump, as a result these were replaced by big-end bolts & nuts with a patented toothed locking arrangement, no further trouble was experienced in this area. Two of the original nickel-chrome steel connecting rods in the 'B' engine were replaced. Two parallel crankshafts drive the 1,420kW main generator through a step-up gearing. The main bearings - whitemetalled steel shells - have only needed four replacements, three on the 'A' unit and one in the 'B' unit. The big-end bearings are of bronze shells with white metal linings. For the twenty four rods in the locomotive, eleven top-half shells and eight bottom halves have been renewed in the 'A' engine and thirteen top halves and thirteen bottom halves likewise in the 'B' engine. The small ends needed practically no attention. They are of the stepped type with greater bearing area over the bottom half, only one has needed renewal, in the 'B' engine. The gudgeon pins are the originals, except for two where new pistons were installed.

Following the end of the War corrosion of the wet type cylinder liners became an issue, not only in this locomotive but in much of the French diesel & railcar fleet, and in many other countries too. Water treatment of a comprehensive nature eliminated this problem, but not before the replacement of sixteen liners in the 'A' unit & fourteen in the 'B' unit.

Statistics available at the intermediate repair effected during 1949 showed:

Miles completed: 600,000

Maximum ovality of the crankpin journals 0.04 tp 0.05mm

Maximum piston wear: 0.2 - 0.3 (on the diameter average over three points)

Fire-ring groove wear: 0.5 - 1.5mm

2nd to 5th ring wear: 0.2 - 1.00mm

Wear in scraper ring grooves: did not exceed 0.1mm

Play in teeth of crankshaft connecting gears: 0.05mm (was 0.03 - 0.04mm when new)

Cylinder liner wear: 1.0mm (at the top, after 499,000 miles, when replaced due to corrosion)

Rateau exhaust gas turbo pressure-charging groups: began to show defects by 1948, as these were non-standard components the delivery of spares was heavily delayed, such that for 129,000 miles one engine ran normally aspirated. The electric control system embodying automatic regulation of engine output according to the inlet air pressure was able to handle this condition, though the power unit suffered greater thermal stresses and the internal condition was dirtier.

Length over buffers (both units): 108ft 5in

Height over radiator fans: 14ft 0.5in

Height over cab roof: 13ft 5.1825in

Maximum width: 9ft 6.625in

Wheelbase (both units): 95ft 11.5in

Wheelbase of bogies: 7ft 10.5in

![]()

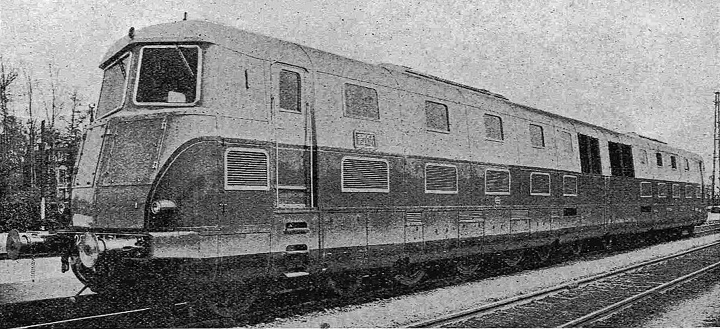

PLM/SNCF 262AD1

The Sulzer powered 262BD1 was one of a pair of twin units ordered by the PLM, the second twin unit, 262AD1 is shown above, this machine was powered by four MAN 1,050hp engines. Fittings on the locomotives were standardised where possible to keep spares to a minimum, likewise the bodyshells reveal much similarity.

The 262AD1 prototype was built by Fives-Lille as the general contractor and the builder of the electrical equipment. SGCM-MAN provided the engines whilst Secheron provided the control system.

The two engines which featured separate oil sumps were operationally independent, and one could be running with the other shut down. They did share a common external lubricating oil reservoir, the use of which may have followed marine practice.

The continuous output was 1900 hp at 700 rev/min, the same engine speed as for the one hour rating of 2100 hp.

In each unit, a separate Saurer BXD 150 hp auxiliary engine with 134 x 180 mm cylinders drove an auxiliary generator to provide the 150-volt auxiliary supply. Whilst normally set to provide 160 hp at 1500 rev/min, in the 262AD1 they were set to run at 1250 rev/min, at which speed 130 hp was available, although demand was not greater than 100 hp. However, if one unit failed, the other could be set to run at 1500 rev/min, in order to feed the auxiliaries of both units.

The power control system had 20 notches, two for starting and shunting, probably of the fixed excitation type, and 18 running notches. Load control was on the Simplex-Sécheron Wheatstone bridge system. This allowed the engine load to be determined by the throttle handle. The latter would also set the engine speed. In notches 1 through 7 the engine ran at 550 to 500 rev/min, in notches 8 to 16 at 650 to 630 rev/min, and notches 17 through 20 at 700 rev/min. The Simplex-Secheron bridge circuit used a Simplex-Cuenod regulator to control main generator excitation via the exciter.

Although somewhat complex in an electrical sense, the Simplex-Secheron bridge circuit did make it relatively easy to provide multiple load points for each engine speed, important back in the days when only a small number of engine speed settings were feasible, three in this case. And it was full load control, protecting the engine against overloading in the event of a malfunction, such as loss of a cylinder, and providing constant loading against such factors as variation of electrical machinery winding temperatures, and hence resistance.

The 262AD1 also had a manual control option. When switched to this mode, the driver controlled excitation manually, with reference to four diesel engine load indicators, which relayed fuel rod position. In view of the fact that full power at the highest speeds was one of the design objectives, early unloading seems to be been unlikely.

The driving wheels had equalized suspension, whilst there was no equalization with the pilot trucks, so as with the 262BD1, the 262AD1 had four-point suspension.

Of note is that the MAN 30/38 'double' engines, at 26.7 tonnes, were considerably lighter than the Sulzer 12LDA31 engines fitted to 262BD1, which weighed 41.2 tonnes. However the 262AD1 generator complement was heavier than that of the 262BD1, and if one takes account of the 262AD1 auxiliary engines, the complete powerplant weight difference was much smaller, about 2 tonnes in favour of the 262AD1.

Both twin units were retired from service during 1955.

Based on articles in Diesel Railway Traction, July 7th 1939, October 1945 (supplement) & August 1950.

Other resources:

CF PLM & Constituents Locomotive Lists 1829-1938 by Dr John Davies, 1996 (2nd Ed.) ISBN 0-646-15102-9

Les prototypes de 4000ch du PLM by Pierre Barry (in La Vie du Rail)

![]()

Review

The two locomotives featured on this page, in conjuction with >>>>>>>>>>>>>>>>> were all built just before the start of World War Two. This event not only precluded the building of additional examples of any of them, but also resulted in changed circumstances following its conclusion such that further building was not required. In any event, in the post-World War Two era the three large types, 262AD1, 262BD1 and DE241 were mechanically obsolete and had more locomotives with their characteristics and capabilities been required in the late 1940s, most likely new bogie designs would have been developed.

Unlike the case in North America, where the EMD E- and F-models of the immediate pre-World War Two era were continued in improved forms after the war, and effectively determined American practice for the first decade thereafter, the influence of European pre-World War Two diesel practice on post-World War Two events was largely indirect.

In the 1950s, SNCF and CFR both returned to the Sulzer double-bank engine in its smaller bore 12LDA28 form, used in their respective 060DA classes. BR also became a big user of the 12LDA28. In part it was probably influenced by what it had seen of the 12LDA31 and other Sulzer engines in service in Europe and elsewhere. And in part there was a faction (London Midland Region), one with considerable sway, that was 'sold on Sulzer'.

The body structure and bogie design of the Am4/4 informed subsequent Swiss electric locomotive practice, including the BLS Ae4/4, SBB Re4/4 and Ae6/6, and eventually found its way back into diesel practice. The CFR 060DA and the VR (Finland) Hr12 had similar structures and bogies that were derived directly from those of the Ae6/6.

The BR Class 33 may be seen as conceptually a latter-day version of the Am4/4, with a later, more powerful version of the Sulzer 8LDA28 engine and electric train heating (DC in this case). At 77 long tons, it was not a lightweight, though.

It has been observed that at the time of their building, the three 4000 hp locomotives had the best power-to-weight ratios of any locomotives in that power category. The obvious comparison is with a two-unit EMD E-series locomotive of the time, which weighed about 285 long tons total, 190 long tons adhesive. Power output was 3600 hp (tractive) for the E2, and 4000 hp (tractive) for the E3, the latter released during 1938. The three European locomotives each had a continuous gross output of 3800 hp. For the 262BD1 and DE241, tractive power could be estimated to be in the vicinity of 3500 hp. For the 262AD1, which had separate auxiliary engines, the tractive power would have been the full 3800 hp.

Thus on a continuous tractive power basis, the power-to-weight ratios were:

EMD E2: 12.6 hp/long ton

EMD E3: 14.0 hp/long ton

262AD1: 17.2 hp/long ton

262BD1: 15.8 hp/long ton

DE241: 16.1 hp/long ton

Thus the European trio definitely had the advantage. However, the highest possible power-to-weight ratio is not always desirable; there has to be enough adhesive weight to do reliably the required haulage job, and often this will point to a locomotive weight that is somewhat higher than the minimum achievable with the designated power equipment and whilst meeting the mechanical design parameters. The latter was often the case in American practice, where very high axle loadings were permissible, a legacy from the steam era, and very high trailing loads demanded very high tractive effort. Also it may be noted that the EMD E-series were fitted with steam heating equipment, which with its associated water tanks added weight in and of itself, as well as often requiring extra locomotive length which also increased weight. In Europe, more modest maximum axle loadings were somewhat of a design constraint, although not anywhere to the same extent that applied to most 'overseas' CMT-gauge systems.

The 4000 hp trio were at the apex when it came to rigid-frame line-service diesel locomotives. However, such technology often occurs on the cusp of a paradigm shift, and so it was in this case. Few rigid-frame line-service diesel locomotives were built after World War Two, with the independent bogie type becoming dominant. When used, the rigid-frame form was typically chosen to address special circumstances. On the other hand, the Am4/4 was the harbinger of the post-World War Two European independent-bogie line-service diesel locomotive.

Other French classes: SNCF 68000 , SNCF 65500 , Early French shunters

Page added March 2nd 2003.

Page updated January 13th 2021.

Return to Sulzer page

Return to Picture menu